A modular prestressed concrete shell and modular shell assembly method

A prestressed and modularized technology, applied in the direction of walls, buildings, building reinforcements, etc., can solve the problems of high construction difficulty, high dismantling difficulty, high cost, etc., to reduce the difficulty and cost of decommissioning, reduce the risk of high-altitude operations on site, and easily The effect of demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

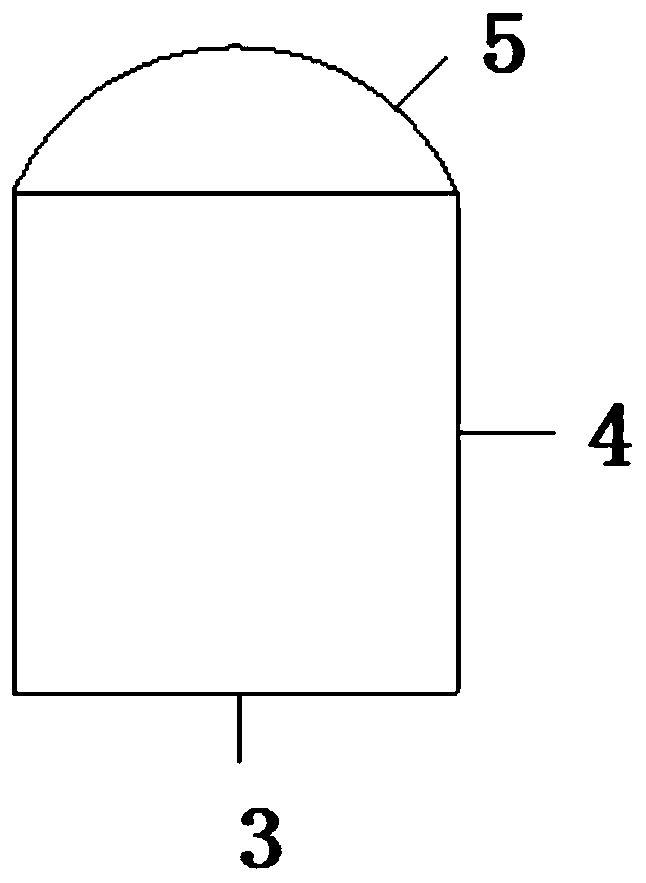

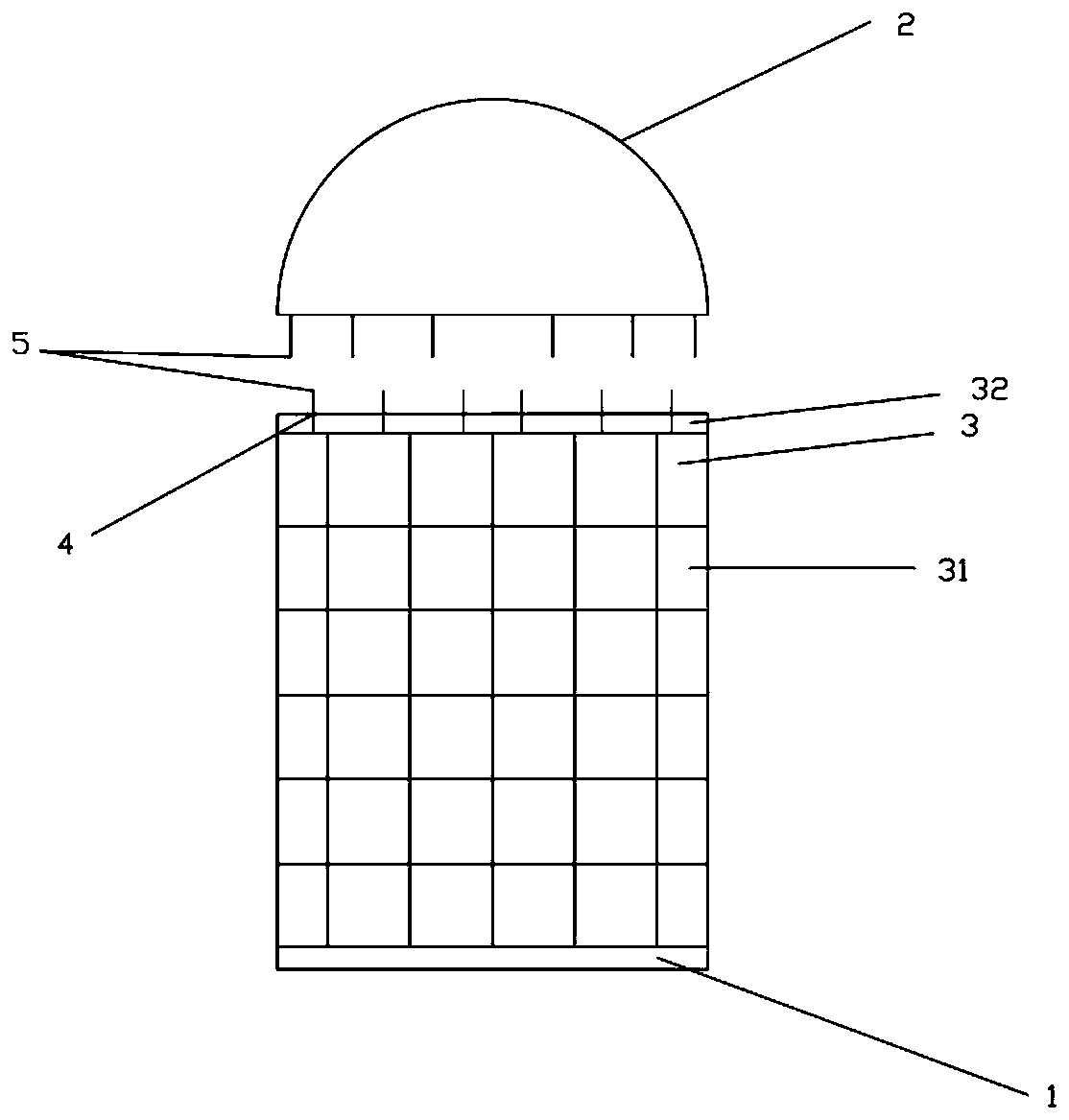

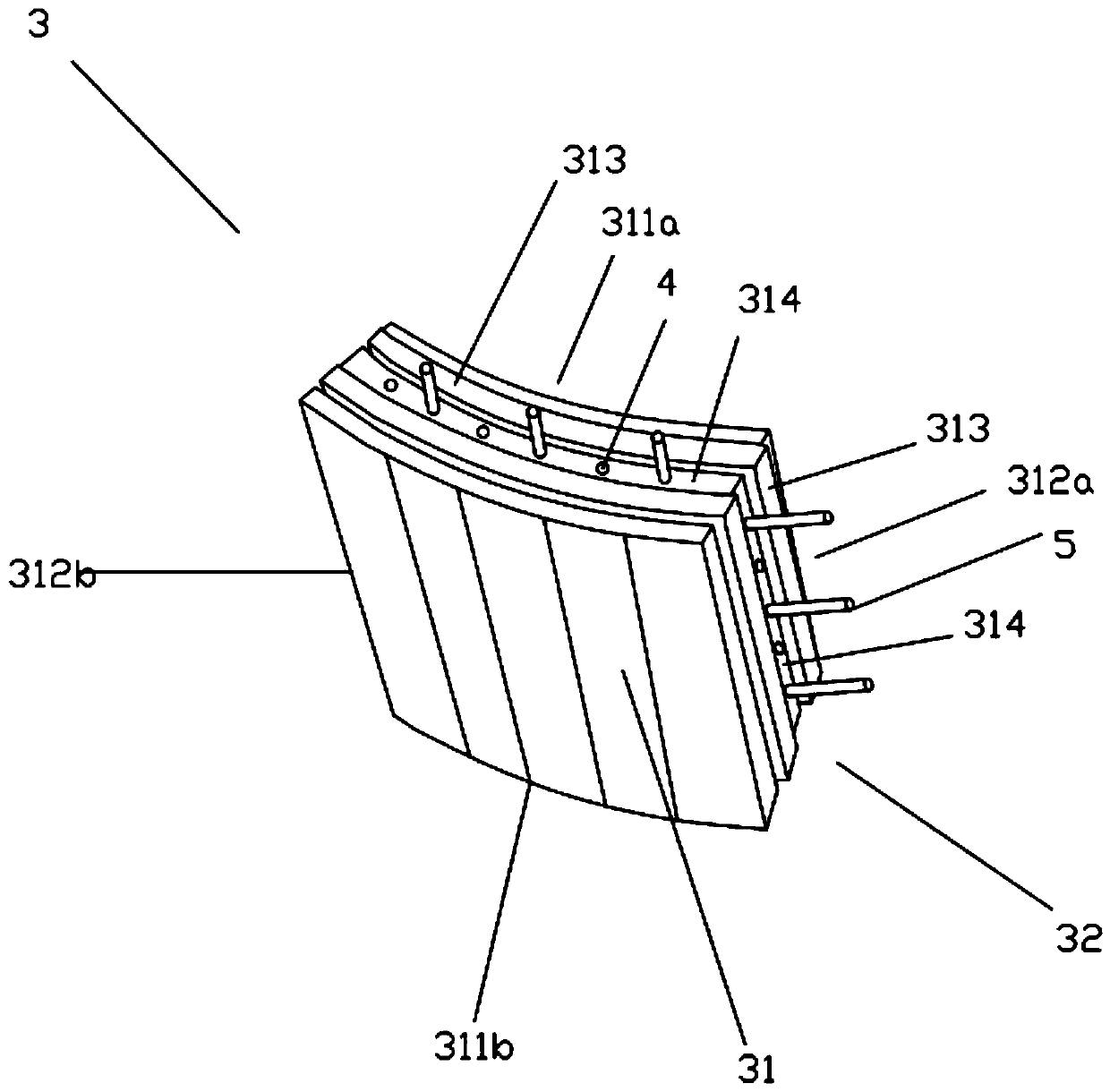

[0037] Such as figure 2 As shown, the modular prestressed concrete shell includes: a bottom plate 1 and a dome 2, and also includes several cylinder shell modules 3, each of which has a main body portion 31 and is arranged on the main body portion 31 The connecting portion 32 on the peripheral surface; the dome 2 and each of the main body parts 31 are provided with at least one set of prestressing tendon tunnels 4 for allowing the prestressing tendons 5 to pass through; the periphery of each of the main body parts 31 The connecting portion 32 on the peripheral surface is plugged with the connecting portion 32 on the outer peripheral surface of another adjacent main body portion 31, and is plugged into the prestressing tendon tunnel 4 of each of the main body portions 31. Stress ribs 5 connect each adjacent main body portion 31, so that several cylinder shell modules 3 are combined and fastened to form a cylinder, one side of the cylinder is poured and connected with the botto...

Embodiment 2

[0048] Such as Figure 5 As shown, Embodiment 2 of the present invention provides a method for assembling a modular prestressed concrete shell, including the following steps:

[0049] S1, pouring the shell bottom plate 1 and the dome 2 of the reinforced concrete structure;

[0050] S2. According to the design size of the shell, the size of each shell shell module 3 is obtained and factory prefabricated;

[0051] S3. Connect each cylinder shell module 3 with the adjacent cylinder shell modules 3 horizontally end-to-end through the connecting portion 31 and the prestressed ribs 5, and fill the splicing gap between the cylinder shell modules 3 with waterproofing , anti-corrosion materials, forming several layers of annular module circles;

[0052] S4. Vertically splice several layers of ring-shaped module circles through the connecting portion 31 of each cylinder shell module 3 and the prestressed ribs 5, and fill the splicing gap between the cylinder shell modules 3 with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com