Stone-waste-residue foam board and treatment method of stone waste residues

A technology of stone waste residue and treatment method, which can be used in applications, household appliances, ceramic products, etc., and can solve problems such as environmental pollution and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

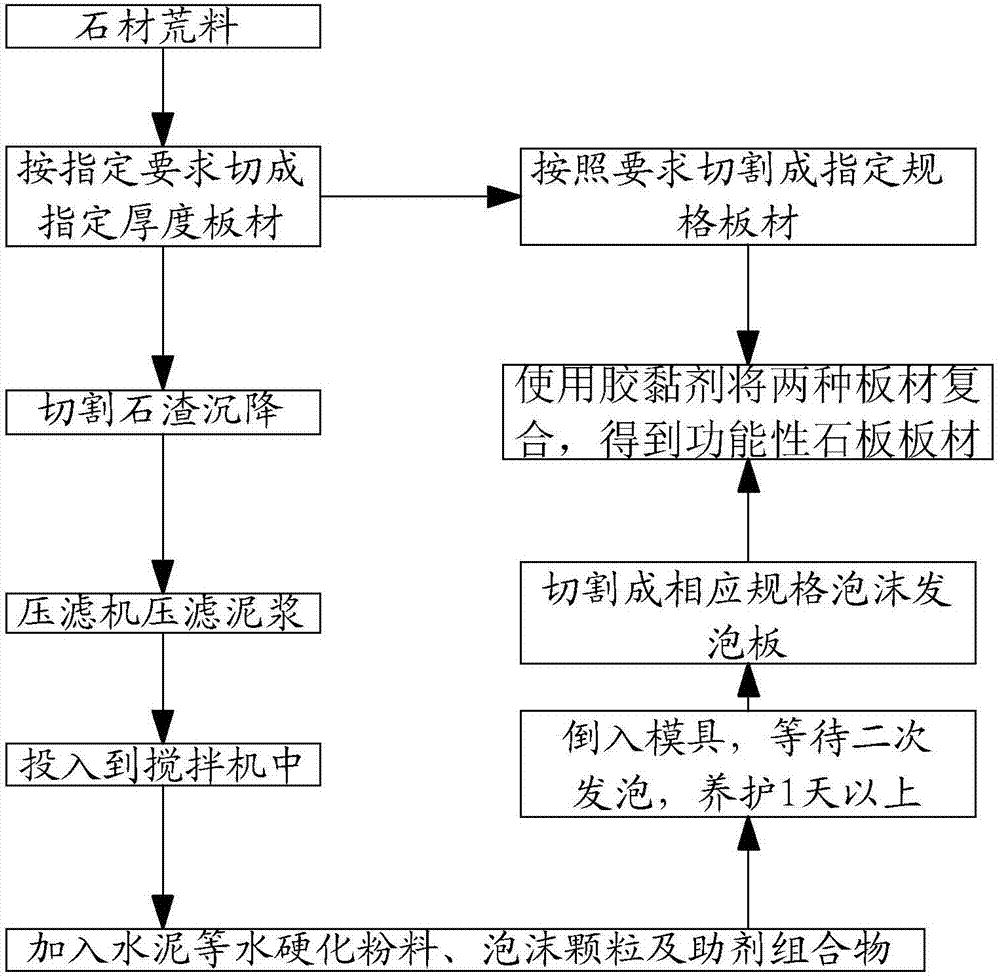

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0023] A stone waste slag foam board related to the present invention is composed of the following components: hydraulic inorganic gelling material: 30-80 parts by weight; stone waste slag: 10-50 parts by weight; EPS foam particles: 0.5-1.5 parts by weight ; Fiber: 0.01-1 parts by weight; Auxiliary: 0-5 parts by weight; Foaming agent: 0-2 parts by weight. Specifically, the hydraulic inorganic cementitious material is cement or a mixture of cement and gypsum, the fiber is selected from glass fiber or nylon fiber, and the auxiliary agent is selected from one of water reducer, early strength agent or air-entraining agent or more.

[0024] In the actual production process of the present invention, appropriate water needs to be added, and how much water needs to be added can be selected according to the actual situ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com