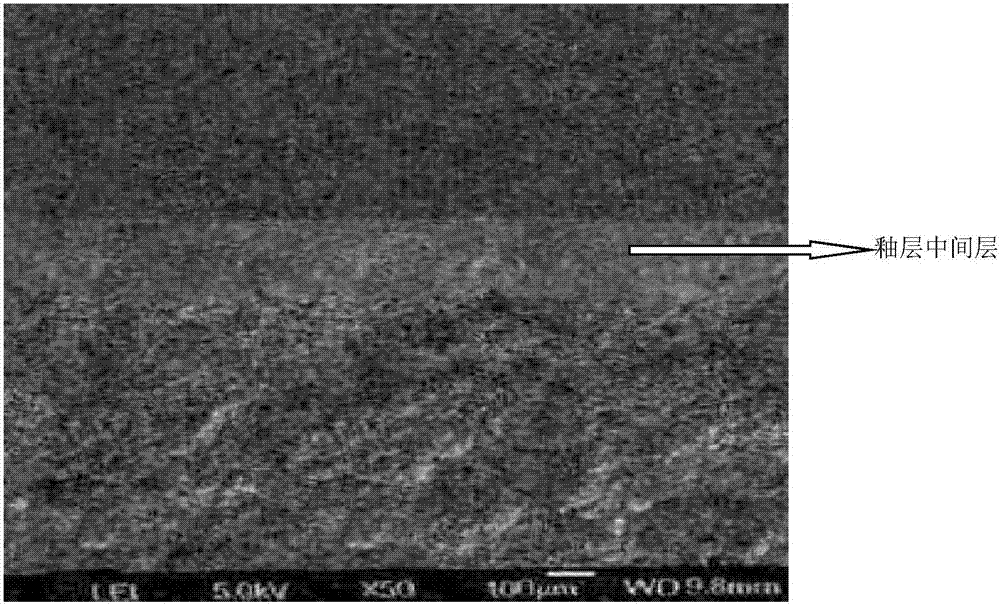

Ceramic inkjet penetrated overglaze containing lepidolite tailings

A technology of ceramic inkjet and lepidolite, which is applied to the field of ceramic inkjet infiltration surface glaze containing lepidolite tailings, can solve the problem of less research on ceramic infiltration surface glaze, etc., and achieves favorable color development, stable performance, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing ceramic ink-jet bleed glaze, comprising the steps of:

[0028] 1) According to the ratio of the above-mentioned ceramic ink-jet bleed glaze, weigh the raw materials and mix them;

[0029] 2) adding an appropriate amount of thickener, debonding agent and water, and wet ball milling to obtain the oozing glaze glaze slurry;

[0030] 3) After sieving and removing iron, it becomes stale to obtain ceramic ink-jet bleed glaze.

[0031] As a further improvement of the above-mentioned preparation method, after sieving and removing iron, an appropriate amount of nano-color auxiliaries is added to the glaze slurry of the oozing glaze, fully stirred and mixed, and then stale.

[0032] As a further improvement of the above-mentioned preparation method, the fineness of the oozing surface glaze slurry is 0.2-0.8% over a 325-mesh sieve.

[0033] As a further improvement of the above preparation method, the density of the ceramic ink-jet bleed glaze is adjusted ...

Embodiment 1

[0040] A ceramic ink-jet seepage surface glaze containing lithium mica tailings, which is composed of the following raw materials in parts by mass: 30 parts of potassium feldspar, 8 parts of albite feldspar, 33 parts of quartz, 3 parts of kaolin, 2 parts of calcined talc, lithium 24 parts of mica tailings.

[0041] Its preparation and use methods include the following steps:

[0042] 1) Wet ball milling: Weigh all the raw materials of the seepage glaze according to the mass percentage and mix them evenly to obtain a mixture, then put the mixture into a ball mill, and then add appropriate amount of methyl, trimer and water into the ball mill respectively, Carry out wet ball milling to control the fineness of the glaze slurry: 0.2% (325 mesh sieve) to obtain the bleed glaze glaze slurry;

[0043] 2) Sieve the bleed surface glaze slurry to remove iron, add 3.7% nano-color auxiliaries accounting for 3.7% of the bleed surface glaze dry material, fully stir and mix evenly, and get ...

Embodiment 2

[0048] A ceramic ink-jet seepage glaze containing lithium mica tailings, which is composed of the following raw materials in parts by mass: 37 parts of potassium feldspar, 10 parts of albite feldspar, 15 parts of quartz, 8 parts of kaolin, 5 parts of calcined talc, lithium 25 parts of mica tailings.

[0049] Its preparation and use methods include the following steps:

[0050] 1) Wet ball milling: Weigh all the raw materials of the seepage glaze according to the mass percentage and mix them evenly to obtain a mixture, then put the mixture into a ball mill, and then add appropriate amount of methyl, trimer and water into the ball mill respectively, Carry out wet ball milling to control the fineness of the glaze slurry: 0.5% (325 mesh sieve) to obtain the oozing glaze glaze slurry;

[0051] 2) Sieve the bleed surface glaze slurry to remove iron, add 3.0% nano-color auxiliaries accounting for 3.0% of the bleed surface glaze dry material, fully stir and mix evenly, and get the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com