Sodium bismuth molybdate nanometer material and preparation method thereof

A nanomaterial, sodium bismuth molybdate technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, can solve the problems of high energy consumption, low material purity, high temperature, etc., and achieve mild reaction conditions, simple process, high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of sodium bismuth molybdate nanomaterial, comprising the following steps:

[0022] 1) 485g (1mol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 4L ethylene glycol under stirring to obtain a bismuth-containing solution, and then 484g (2mol) Na 2 MoO 4 2H 2 O is dissolved in another part of 4L ethylene glycol with stirring to obtain a molybdenum-containing solution, and then the two are mixed and stirred evenly to obtain a mixed solution;

[0023] 2) Add a mixture of 4L ethanol and 2L deionized water to the mixture, stir the obtained precursor evenly, transfer it to a sealed 20L autoclave, heat up to 200°C and react for 2 hours, then cool the reactor naturally to room temperature, the obtained The product was centrifugally filtered, washed with deionized water, and the obtained powder was dried at 120° C. for 4 hours to obtain sodium bismuth molybdate nanopowder.

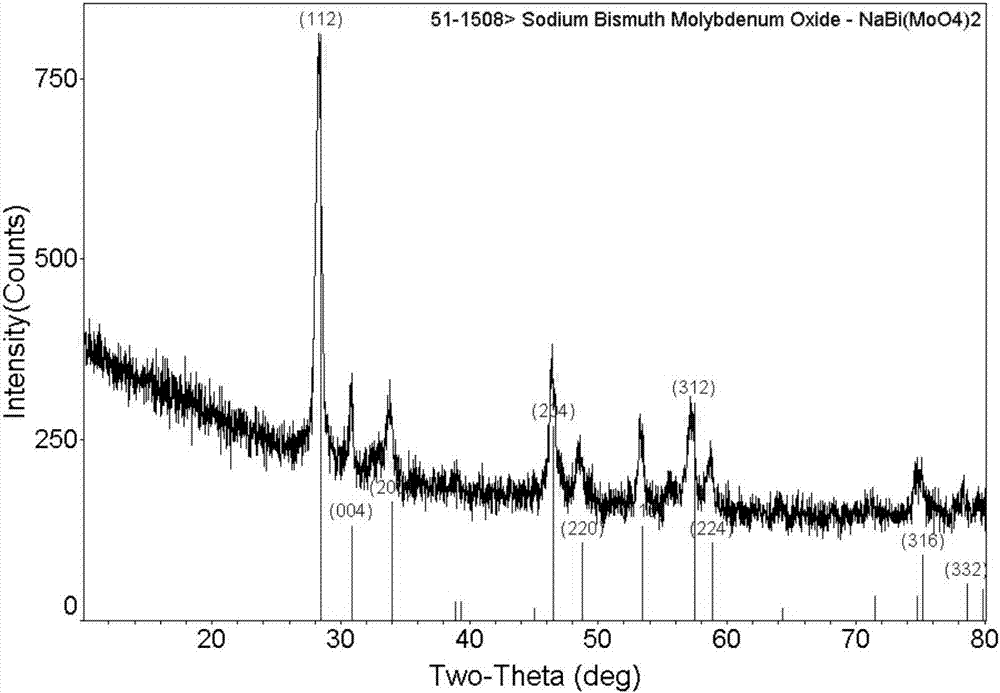

[0024] The product obtained in this embodiment is analyzed by X-ray diffraction, and the X...

Embodiment 2

[0026] A preparation method of sodium bismuth molybdate nanomaterial, comprising the following steps:

[0027] 1) 4.85g (10mmol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 80mL of ethylene glycol under stirring to obtain a bismuth-containing solution, and then 4.84g (20mmol) Na 2 MoO 4 2H 2 O is dissolved in another part of 80mL ethylene glycol with stirring to obtain a molybdenum-containing solution, and then the two are mixed and stirred evenly to obtain a mixed solution;

[0028] 2) Add a mixture of 80mL ethanol and 40mL deionized water to the mixture, stir the obtained precursor evenly, transfer it to a sealed 500mL autoclave, heat up to 120°C for 12 hours, then cool the autoclave to room temperature naturally, and get The product was centrifugally filtered, washed with deionized water, and the obtained powder was dried at 80° C. for 12 hours to obtain sodium bismuth molybdate nanopowder.

[0029] X-ray diffraction analysis of the product obtained in this example shows tha...

Embodiment 3

[0031] A preparation method of sodium bismuth molybdate nanomaterial, comprising the following steps:

[0032] 1) 4.85g (10mmol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 400mL ethylene glycol under stirring to obtain a bismuth-containing solution, and then 4.84g (20mmol) Na 2 MoO 4 2H 2 O is dissolved in another part of 400mL ethylene glycol with stirring to obtain a molybdenum-containing solution, and then the two are mixed and stirred evenly to obtain a mixed solution;

[0033] 2) Add a mixture of 200mL ethanol and 100mL deionized water to the mixture, stir the obtained precursor evenly, transfer it to a sealed 1.5L autoclave, heat up to 160°C for 4 hours, and then cool the autoclave to room temperature naturally. The obtained product was centrifugally filtered, washed with deionized water, and the obtained powder was dried at 100° C. for 4 hours to obtain bismuth sodium molybdate nanopowder.

[0034] X-ray diffraction analysis of the product obtained in this example shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com