Straightening equipment based on bent steel bar in electric power tower

A technology for power iron towers and steel bars, applied in the field of steel bar processing devices, can solve the problems of inconvenient installation of a straightening machine, inconvenient handling, easy to scratch oneself, etc., and achieves the effects of simple structure, avoiding displacement or shaking, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

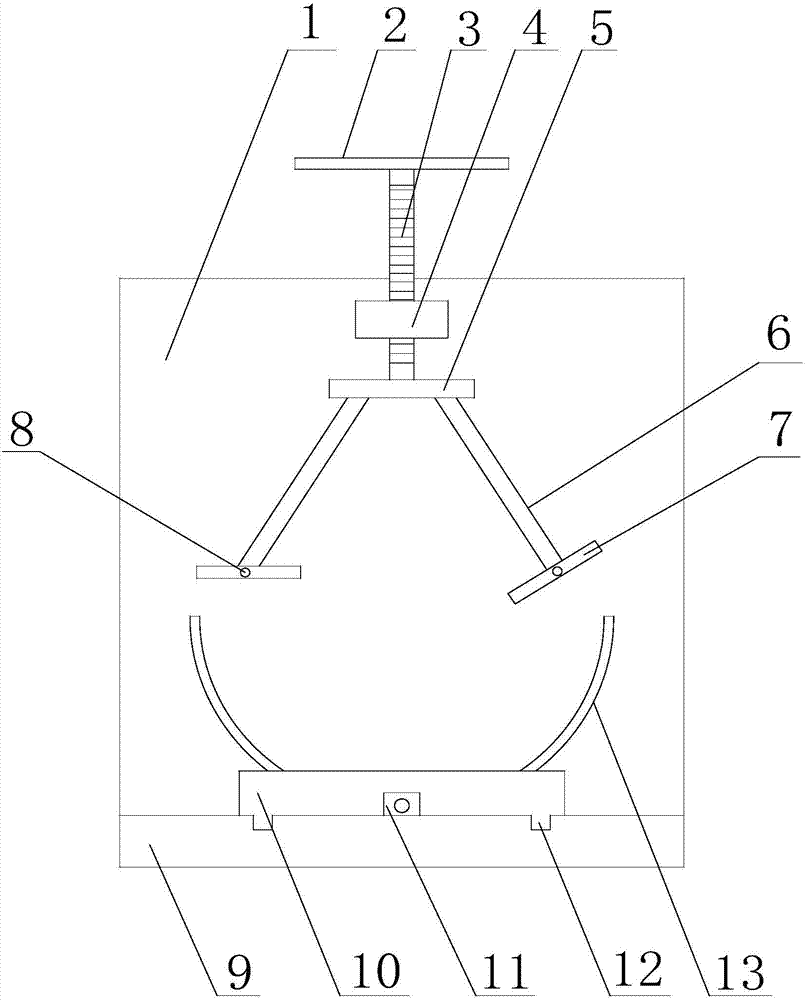

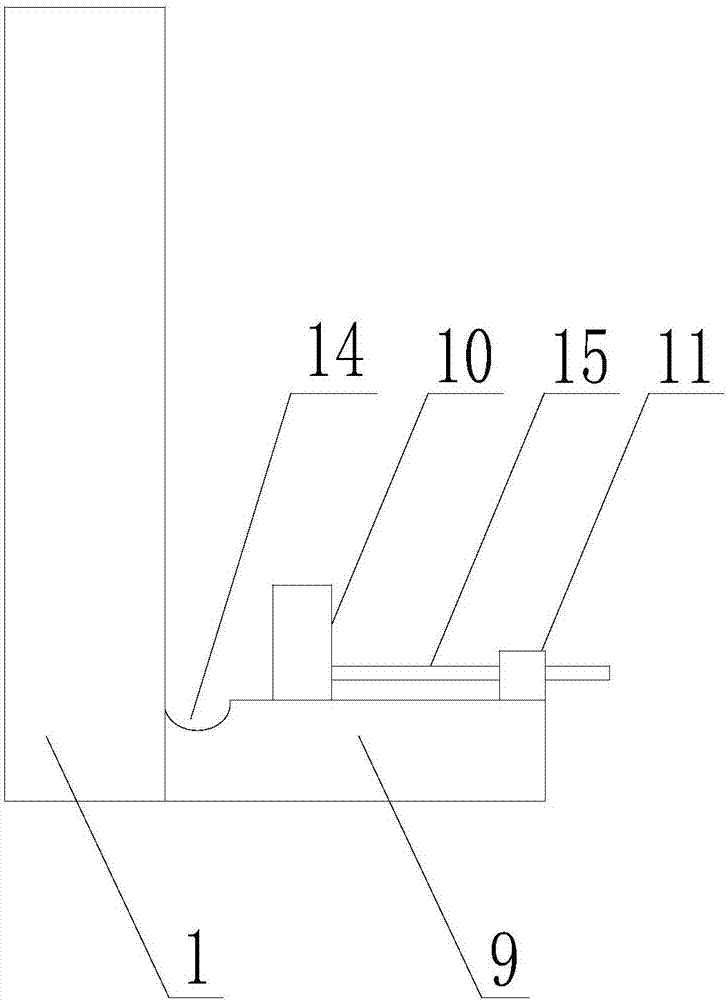

[0023] like figure 1 , figure 2 As shown, the present invention is based on a straightening device for bending steel bars in an electric power tower, including a back plate 1, which is a rectangular structure, and a boss 9 is provided on the side wall of the back plate 1, and the boss 9 is also a rectangular structure. , the boss 9 is used to place the steel bar 13 to be straightened, and the top of the boss 9 is provided with an arc-shaped groove 14. Since the steel bar 13 itself is in the shape of a cylinder, it is easy to fall when placed directly on the boss 9, which affects the Straighten the steel bar 13, so the arc-shaped groove 14 can position the steel bar 13, so that it can be quickly placed on the boss 9. The top of the boss 9 is also provided with a chute and a movable plate 10, which can move The bottom of the board 10 is provided with a sliding block 12 that matches the sliding groove, the sliding block 12 is located in the sliding groove, and the sliding block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com