Long-strip-shaped steel plate straightening machine

A straightening machine and long strip technology, applied in the field of straightening machines, can solve the problems of complex structure and high cost of the straightening machine, and achieve the effects of simple structure, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

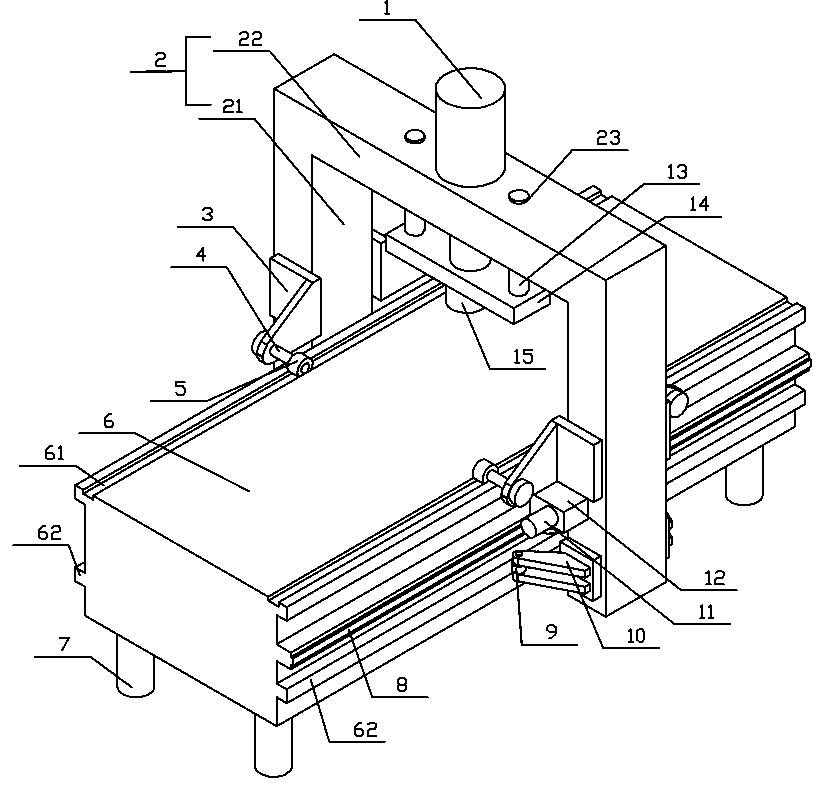

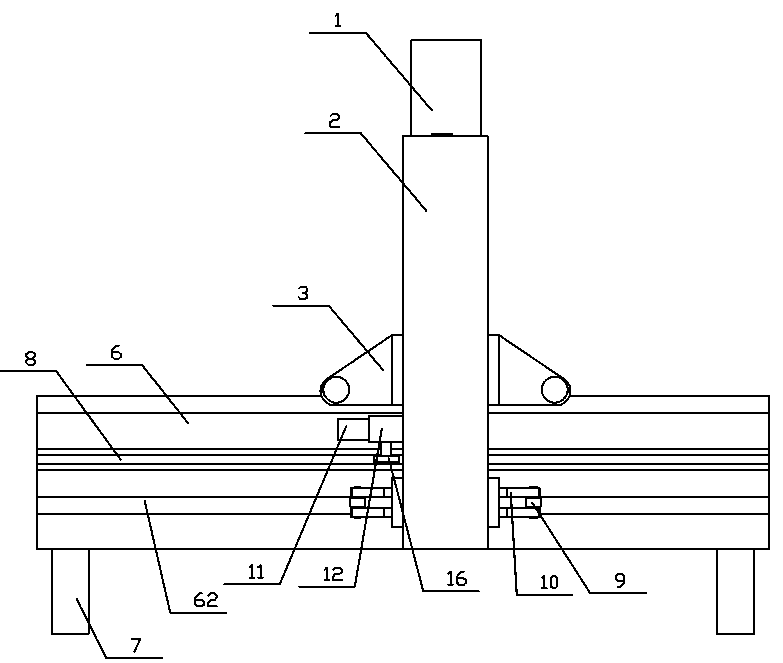

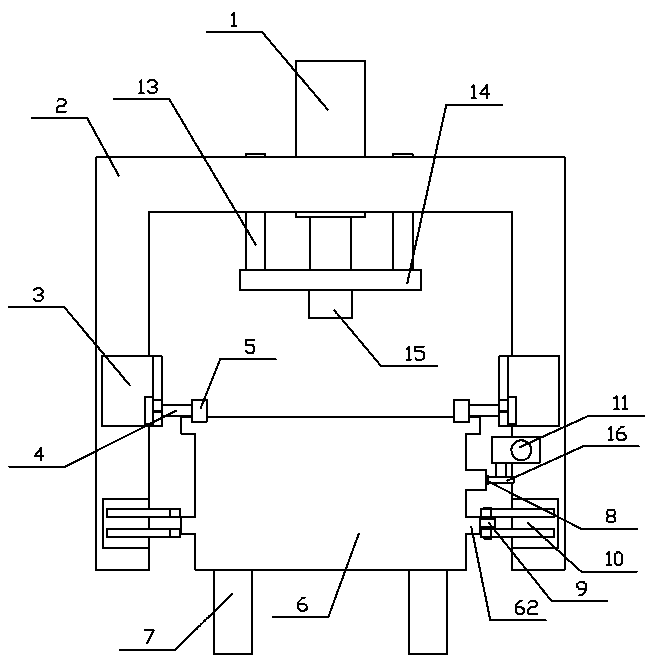

[0012] see Figure 1-3 , the present embodiment includes a rectangular workbench 6, the four corners of the bottom of the workbench 6 are equipped with feet 7, the top surface of the workbench 6 is a working plane, two grooves 61 are arranged on both sides of the top of the workbench 6, and the two grooves 61 are equipped with There is a gantry 2 that can move along the groove 61. A roller bracket 3 is installed on both sides of the two columns 21 of the gantry 2. Each roller bracket 3 is fixed with a wheel shaft 4, and the wheel shaft 4 extends to the workbench 6. And the end portion is equipped with roller 5 through bearing, and roller 5 rolls in groove 61, and oil cylinder 1 is housed in the middle of gantry 2 top crossbeam 22, and crossbeam 22 is positioned at oil cylinder 1 both sides and is provided with through hole 23, and straight line is housed in through hole 23 Bearing, the lower end of the piston rod of oil cylinder 1 is fixedly equipped with a connecting plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com