Correcting tool of shield tunneling machine shell and method for correcting shield tunneling machine shell

A technology of shield machine and shell, which is applied in the field of shield machine, can solve the problem of inaccurate calibration of shield machine shell and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

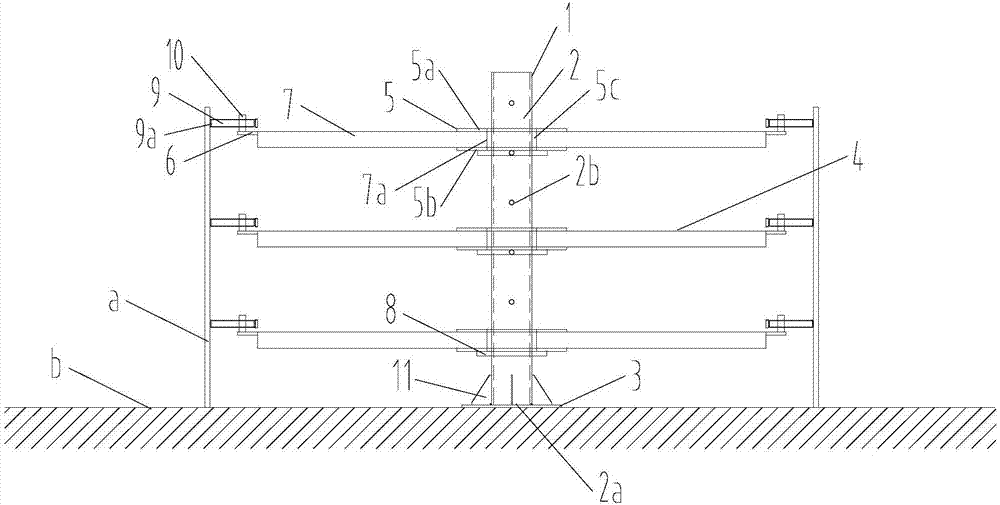

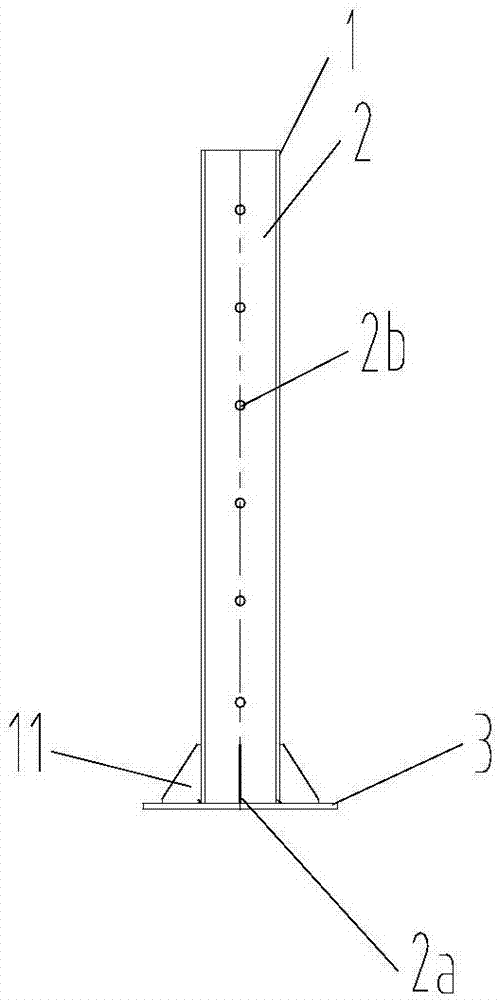

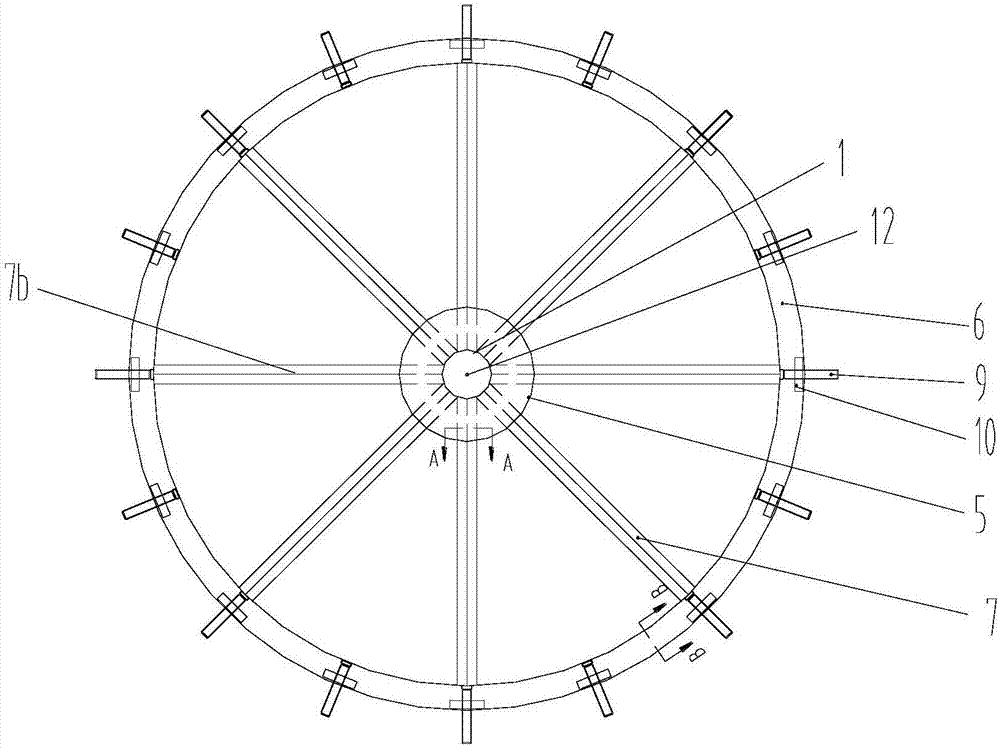

[0035] Embodiment 1 of the present invention provides a calibration tool for the shield machine shell, which is suitable for fine calibration of the shield machine shell a, wherein the shield machine shell needs to be rough-machined after being rolled to form, and then fine-tuned. Machining, fine correction refers to the last circle calibration in the finishing process, shield machine shell a includes front shield, middle shield and back shield. figure 1 It is a schematic structural diagram of the correction tool for the shield machine shell provided by the embodiment of the present invention. Such as figure 1 As shown, the calibration tooling of the shield machine shell includes: a support assembly 1 and a calibration assembly 4 . figure 2 It is a schematic structural diagram of the support assembly provided by Embodiment 1 of the present invention. Such as figure 2 As shown, the support assembly 1 includes: a reference post 2 and a reference seat 3, the first end 2a of ...

Embodiment 2

[0051] Embodiment 2 of the present invention provides a method for calibrating the shell of a shield machine using the calibration tool provided in Embodiment 1. Figure 6 It is a flow chart of the method for calibrating the shell of the shield machine provided by the embodiment of the present invention. Such as Figure 6 As shown, the method includes:

[0052] Step 1: Measure the perimeter of the shield machine shell along the outer wall of the shield machine shell. During specific measurement, multiple measurements can be made at different positions of the shield machine shell a, and the average value of the measurement results can be taken, so that the circumference of the outer wall of the shield machine shell a can be obtained more accurately.

[0053] Step 2: Draw the outline of the reference circle on the workbench. The circumference of the reference circle is the same as the circumference of the outer wall of the shield machine shell, and mark the center of the refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com