A quick peeling method for pepper freezing

A pepper, fast technology, applied in the field of pepper freezing and rapid peeling, can solve the problems of pepper seed damage, damage seeds, reduce the taste of pepper, etc., achieve the effect of pure flavor and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

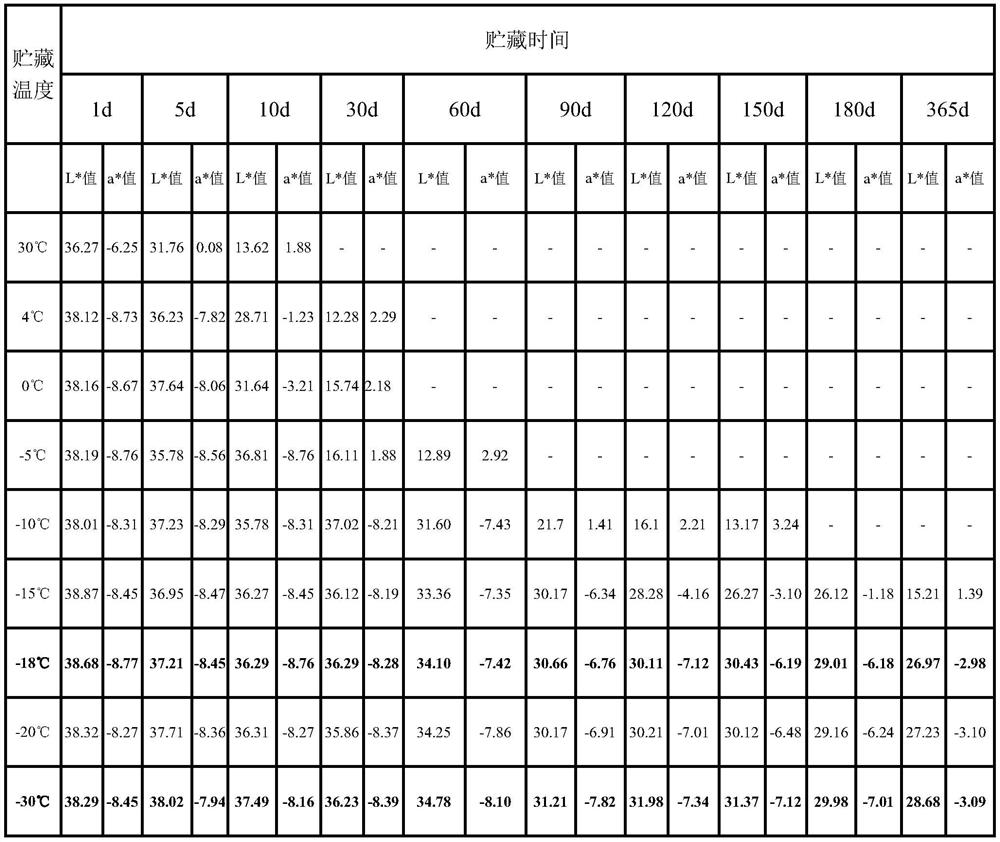

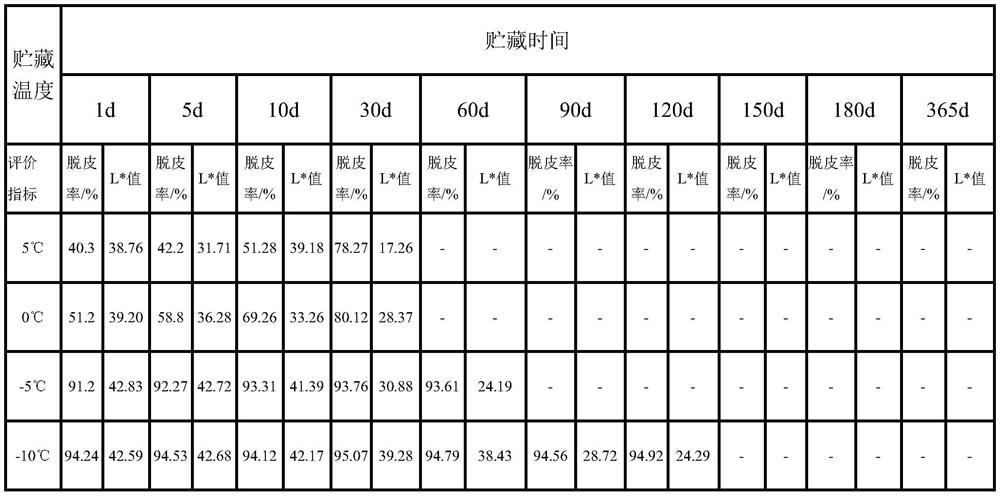

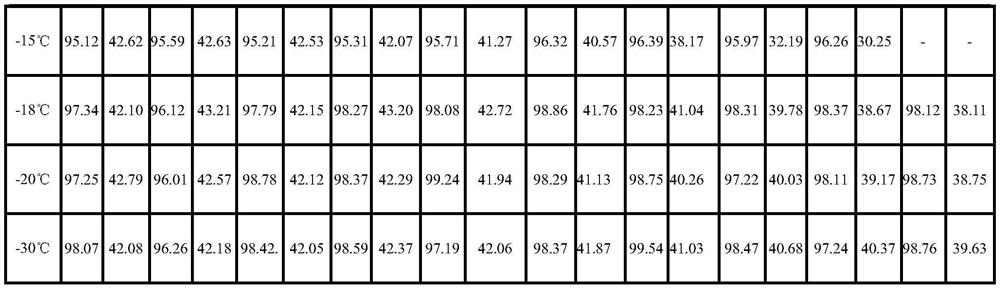

Examples

Embodiment 1

[0026] A kind of pepper freezing quick peeling method is characterized in that, comprises the following steps:

[0027] (1) pre-cooling

[0028] Fresh peppers are washed after picking to remove sediment and pesticide residues, and remove peppercorns floating on the water surface; fresh peppers are pre-cooled at 0°C for 12 hours, and can be frozen when the center temperature of peppercorns drops to 0°C;

[0029] (2) Frozen

[0030] Put the pre-cooled fresh pepper into the freezer at a temperature below -20°C. When the center temperature of the fruit grains is below 0°C and there is a frozen sample, seal it in a sealed bag and store it in a freezer at a temperature of -18°C for later use;

[0031] (3) Peeling

[0032] Fresh peppers refrigerated for 10 hours are immersed in water, soaked for 3 hours, and the fruit stems are removed. They are divided into 3 grades according to the diameter: grade 1 for those less than 4.5mm, grade 2 for 4.5-5.5mm, grade 3 for those larger than 5...

Embodiment 2

[0034] A kind of pepper freezing quick peeling method is characterized in that, comprises the following steps:

[0035] (1) pre-cooling

[0036] Fresh peppers are washed after picking to remove sediment and pesticide residues, and remove peppercorns floating on the water surface; fresh peppers are pre-cooled at 5°C for 5 hours, and can be frozen when the temperature of the center of the peppercorns drops to 5°C;

[0037] (2) Frozen

[0038] Put the pre-cooled fresh pepper into the freezer at a temperature below -20°C. When the center temperature of the fruit grains is below 0°C and there is a frozen sample, seal it in a sealed bag and store it in a freezer at a temperature of -30°C for later use;

[0039] (3) Peeling

[0040] Fresh peppers refrigerated for 3 months are immersed in water, soaked for 24 hours, and the fruit stems are removed. They are divided into 3 grades according to the diameter: grade 1 for those less than 4.5mm, grade 2 for 4.5-5.5mm, grade 3 for those la...

Embodiment 3

[0042] A kind of pepper freezing quick peeling method is characterized in that, comprises the following steps:

[0043] (1) pre-cooling

[0044] Fresh peppers are washed after picking to remove sediment and pesticide residues, and remove peppercorns floating on the water surface; fresh peppers are pre-cooled at 2°C for 10 hours, and can be frozen when the temperature of the center of peppercorns drops to 3°C;

[0045] (2) Frozen

[0046] Put the pre-cooled fresh pepper into the freezer at a temperature below -20°C. When the center temperature of the fruit grains is below 0°C and there is a frozen sample, seal it in a sealed bag and store it in a freezer at a temperature of -20°C for later use;

[0047] (3) Peeling

[0048] Fresh peppers refrigerated for 12 months are soaked in water, soaked for 15 hours, and the fruit stems are removed. They are divided into 3 grades according to the diameter: grade 1 for those less than 4.5mm, grade 2 for 4.5-5.5mm, grade 3 for those larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com