Hollow coil winding equipment

A technology of winding equipment and hollow coils, which is applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve unsolved technical problems and other problems, and achieve the effect of simple structure, complete protection and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

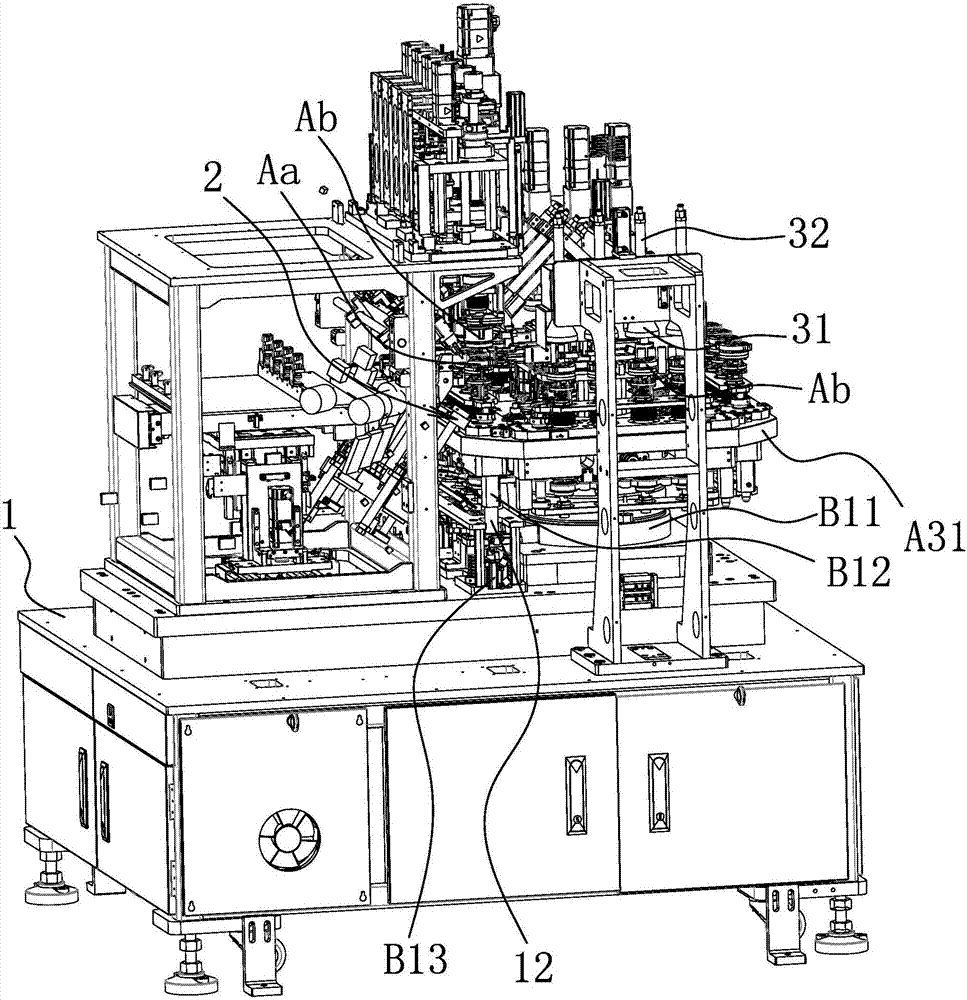

[0087] Such as figure 1 As shown, the hollow coil winding equipment includes a frame 1, on which a protective cover 11 is arranged, and the protective cover 11 is square and made of transparent glass.

[0088] The protective cover 11 has multiple functions of protection and convenience for observation.

[0089] Secondly, each corner of the bottom of the frame 1 is respectively provided with a supporting foot and / or a foldable traveling wheel. The provided supporting feet are convenient for placement and positioning, and the provided foldable walking wheels are convenient for moving.

[0090] Such as Figure 1-4 As shown, a turntable A31 is provided on the frame 1 and is connected to the turntable drive mechanism B1. The turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com