Secondary slide block core pulling mechanism for plastic mould

A core-pulling technology for plastic molds and sliders, which is applied in the field of secondary slider core-pulling mechanisms for plastic molds. The effect of core pulling time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

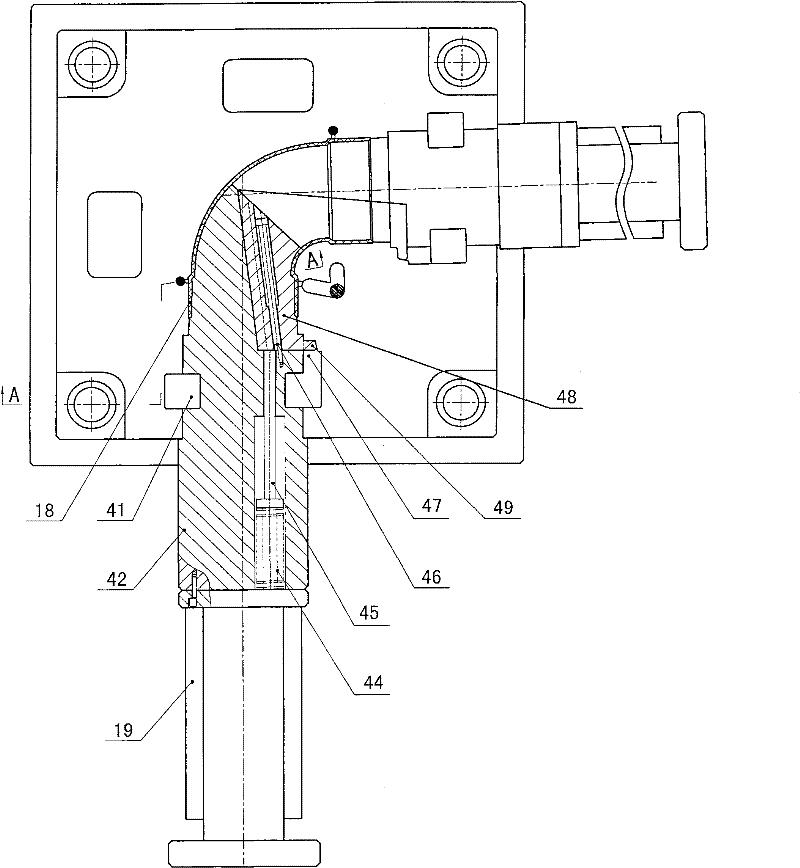

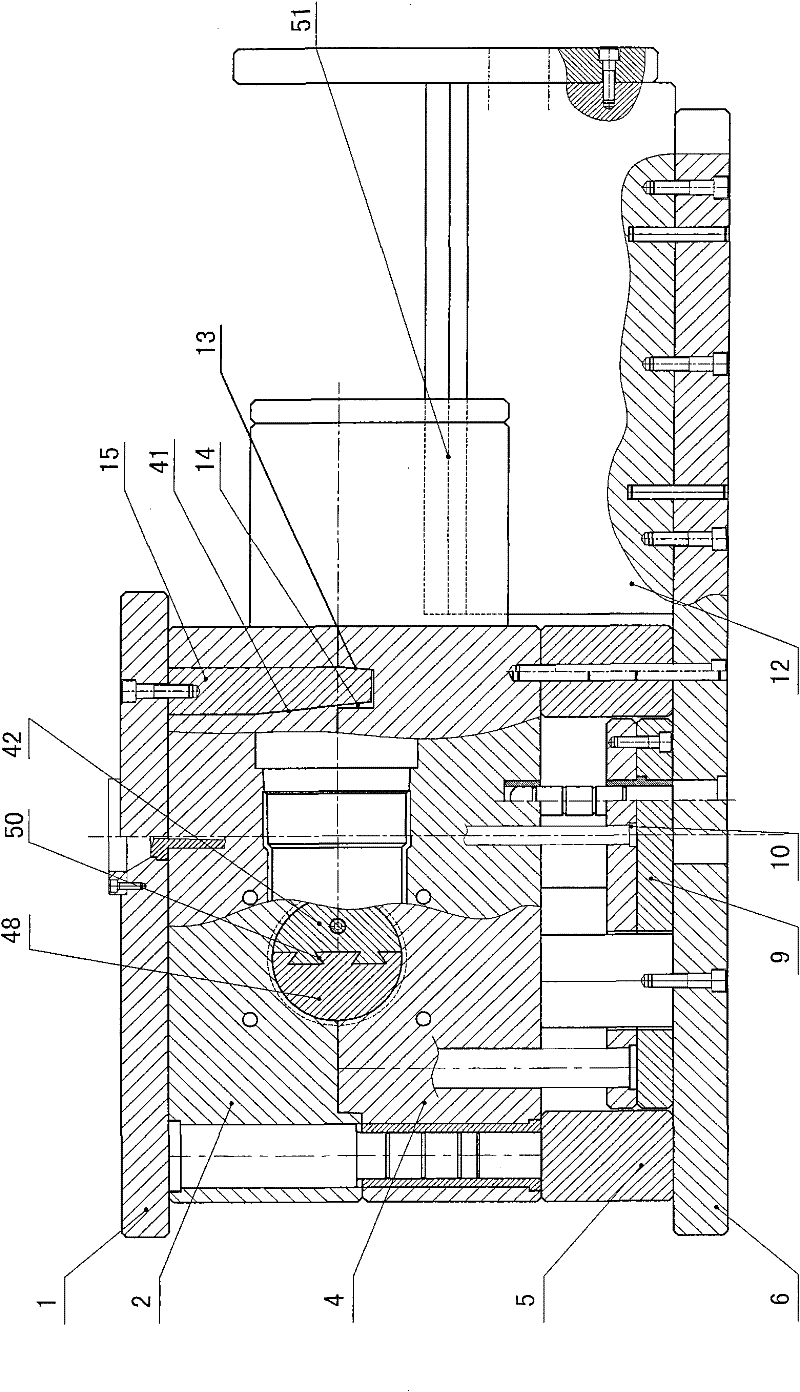

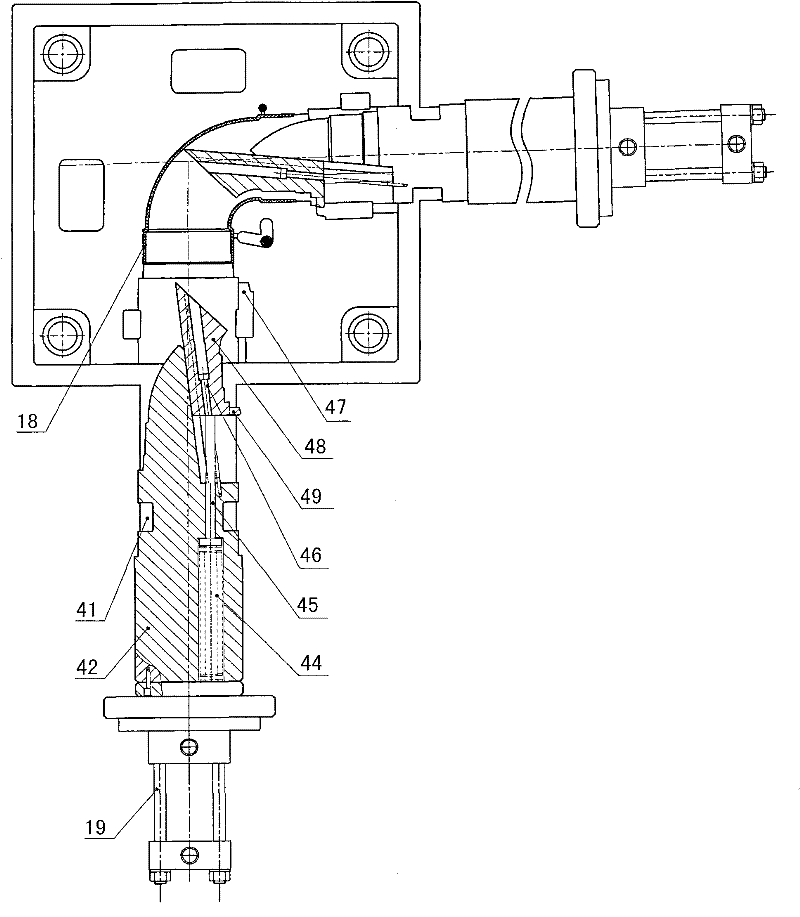

[0010] The invention relates to a plastic mold secondary slider core-pulling mechanism, such as Figure 1-Figure 3 As shown, it includes an upper doubler plate 1 and a lower doubler plate 6, the upper doubler plate 1 is connected with the fixed formwork 2, the mold foot 5 and the top plate 9 are installed on the lower doubler plate 6, the ejector rod 10 is installed on the top plate 9, and the movable mold foot 5 is installed The template 4, the fixed template 2 and the movable template 4 form a mold cavity. There is a molded plastic part 18 in the mold cavity. Slider 42, the outer slider stretches into the inner wall of the plastic part 18, the inner slider 48 is arranged inside the outer slider 42, a compression spring 44 and a push rod 45 are installed in the outer slider 42, and the push rod 45 is connected with the inner slider 48 , the lock module 15 is installed in the fixed formwork 2, and the two sides of the lock module are respectively formed with a slope 14 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com