Method for analyzing and testing charge-discharge performance and charge-discharge mechanism of lithium battery

A charge and discharge performance, analysis and testing technology, applied in the field of lithium battery charge and discharge test, can solve the problems of inability to cooperate with battery test equipment and high and low temperature test chambers, inability to effectively detect changes in electrode products, lack of versatility, etc., to achieve saving Expensive, reliable results, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

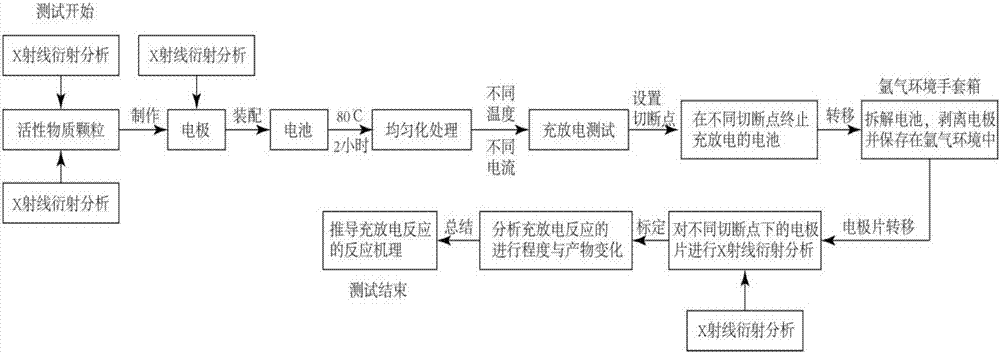

[0048] A method for analyzing and testing lithium battery charging and discharging performance and charging and discharging mechanism, such as figure 1 shown, including the following steps:

[0049] Step 1, making the electrode active material particles into lithium battery electrodes, performing X-ray diffraction analysis on the electrode active material particles and lithium battery electrodes respectively, and then assembling the lithium battery electrodes into lithium batteries;

[0050] The specific method of step 1 is: after performing X-ray diffraction analysis on the active material particles used to make lithium battery electrodes, use the electrode active material particles to make lithium battery electrodes; then perform X-ray diffraction analysis on lithium battery electrodes, and determine Whether the phase composition of the active m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com