A power-driven two-phase loop active regulation energy storage and release system and method

A power-driven, phase-loop technology, applied in thermal storage equipment, lighting and heating equipment, indirect heat exchangers, etc. Lack of initiative and other problems, to achieve the effect of ensuring active control performance, simple structure, and improving flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

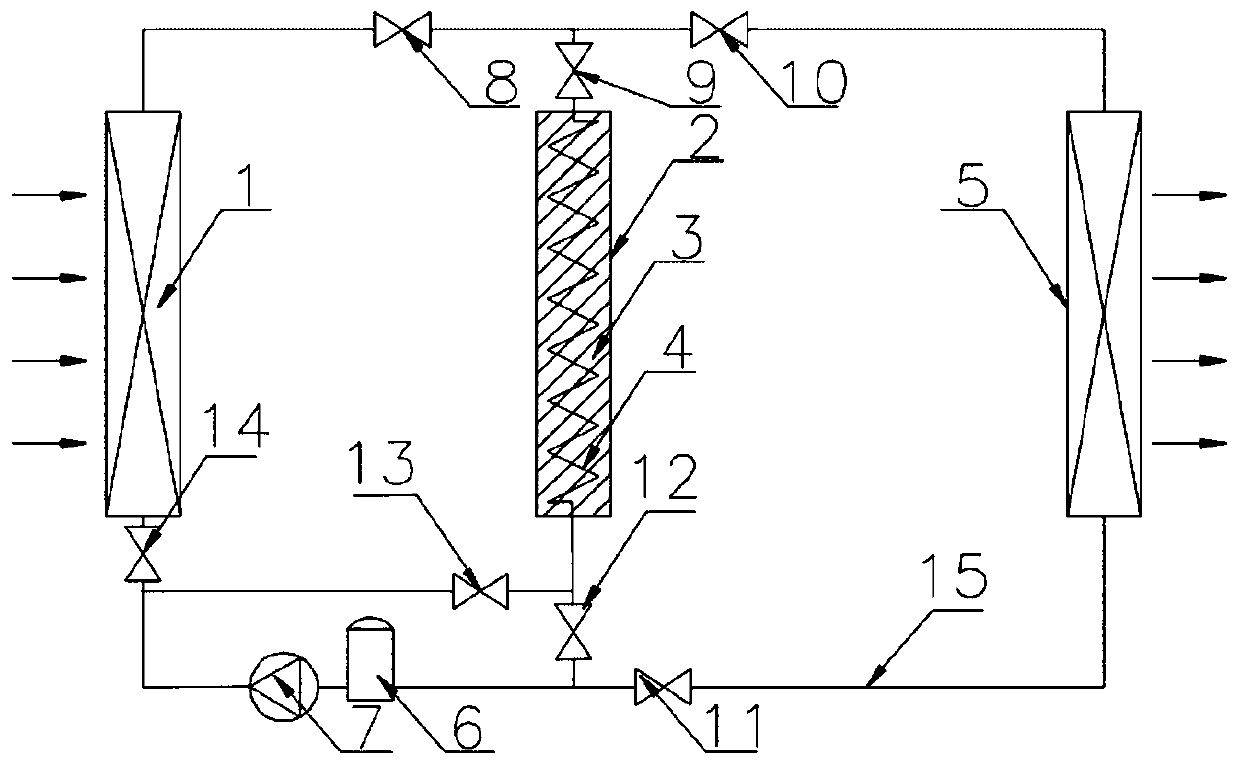

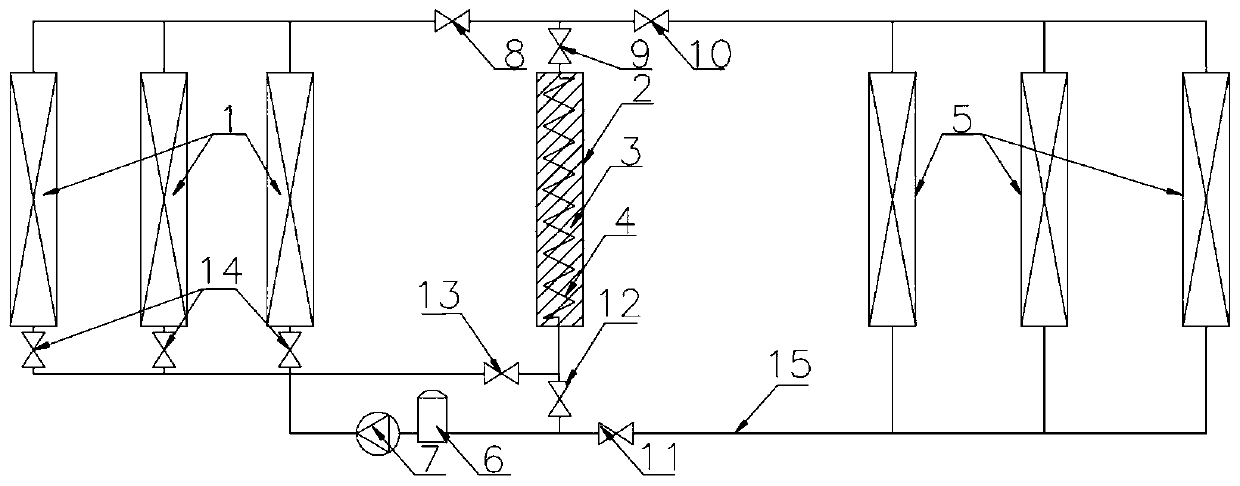

[0025] figure 1 It is a schematic diagram of the principle and structure of a power-driven two-phase loop active regulation energy storage and release system, including source side heat exchanger 1, accumulator 2, energy storage material 3, energy storage heat exchanger 4, user side Heat exchanger 5, liquid reservoir 6, power unit 7, first valve 8, second valve 9, third valve 10, fourth valve 11, fifth valve 12, sixth valve 13 and seventh valve 14; The source-side heat exchanger 1, the energy-storage heat exchanger 4, the user-side heat exchanger 5, the liquid reservoir 6 and the power unit 7 form a closed loop space through the connecting pipeline 15 and corresponding valves, and its interior is filled with Inject liquid low boiling point fluid working medium. The energy storage material 3 can be one of paraffin, sodium sulfate decahydrate, or bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com