Spiral type fabricated tunnel structure and construction method thereof

A technology of tunnel structure and construction method, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., and can solve problems such as the application of difficult and short tunnels, the problem of tool wear, and the increase in project cost, so as to reduce the time of exposure to the air , The effect of reducing the volume of mechanical equipment and reducing the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments. The following circumferential direction refers to the circumferential direction of the tunnel, and the axial direction refers to the axial direction of the tunnel.

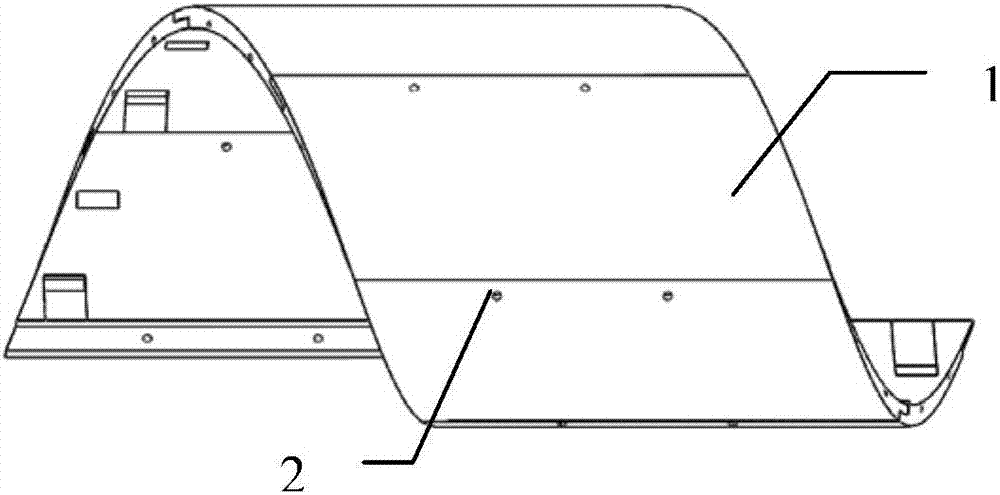

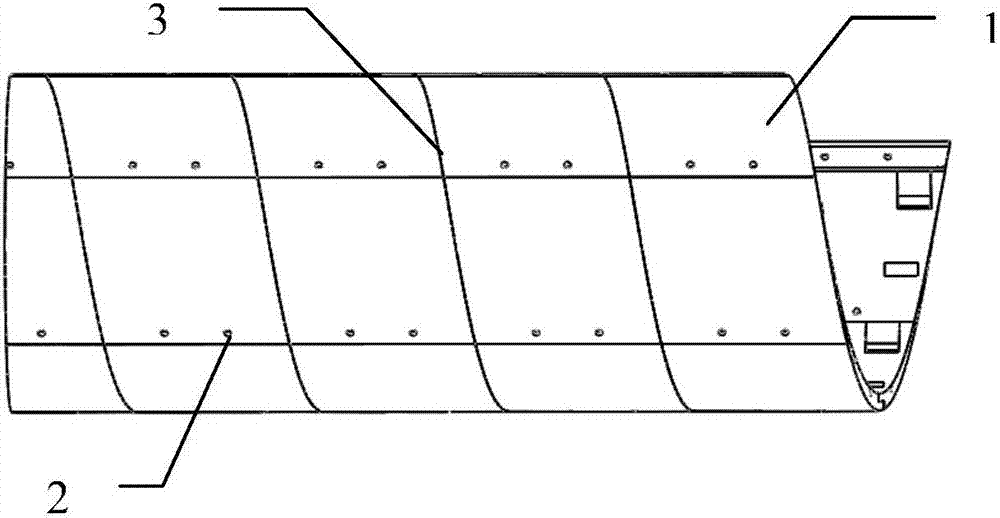

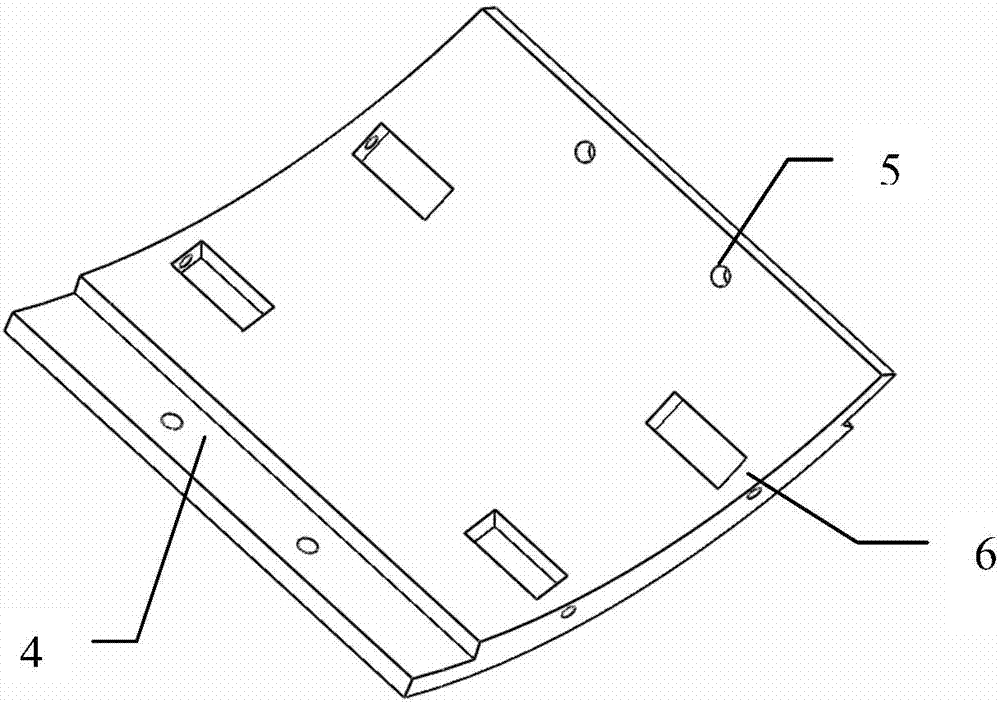

[0019] Such as Figure 1 to 6 As shown, a spiral fabricated tunnel structure is constructed by assembling segments 1 through connecting bolts 2; the segments are provided with an arc matching the inner wall of the tunnel along the circumferential direction of the tunnel. The four end faces are all connecting surfaces connected to adjacent segments, and the connecting surface of the segment 1 perpendicular to the longitudinal direction of the tunnel is a curved surface that conforms to the relationship between the pitch and the helix angle. In other words, this curve refers to When the segments are assembled in the tunnel, the connecting surface can be provided with a curvature along the longitudinal directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com