Comprehensive recovery method for rare earth, aluminum and silicon in aluminum-silicon waste

A rare earth and aluminum silicon technology, applied in the direction of improving process efficiency, can solve the problems of long process, low rare earth yield, large alkali consumption and water consumption, etc., and achieve easy industrial production, increase yield and purity, and waste water The effect of small emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

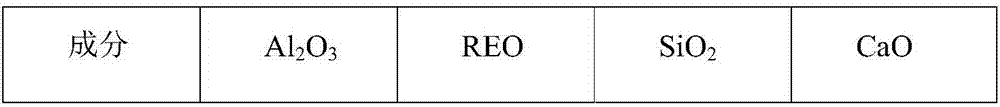

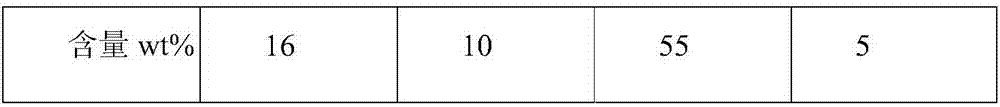

Embodiment 1

[0036] After slurrying the rare earth-containing aluminum-silicon waste, the liquid-solid ratio is 3:1, add 1mol / L hydrochloric acid to treat the rare-earth-containing aluminum-silicon waste, control the pH value of the reaction process to 2.5, and mechanically stir at 10°C (200rad / min) After leaching for 12 hours, control the pH of the solution at the end of the reaction to 2.0; filter to obtain the acid leaching solution containing rare earth and aluminum and silicon-rich slag. The leaching rates of aluminum, rare earth and silicon (all as oxides) in the acid leaching solution containing rare earth and aluminum were 66.9%, 85.3% and 3.5%, respectively.

Embodiment 2

[0040] Before the acid leaching reaction, the rare earth-containing aluminum-silicon waste is crushed, ground, and slurried. After sizing, the liquid-solid ratio is 4:1. Add 3mol / L hydrochloric acid to treat rare earth-containing aluminum-silicon waste, control the pH value of the reaction process to 2.0, leaching with mechanical stirring (180rad / min) at 20°C for 8h, and control the pH of the solution at the end of the reaction=1.8; filter to obtain rare earth and aluminum-containing pickling solution and silicon-rich slag. The leaching rates of aluminum, rare earth and silicon in the acid leaching solution containing rare earth and aluminum (all calculated as oxides) were 73.6%, 89.2% and 4.2%, respectively.

Embodiment 3

[0042] The liquid-solid ratio is 5:1 after slurrying the rare earth-containing aluminum-silicon waste. Add 5mol / L hydrochloric acid to treat the aluminum-silicon waste containing rare earth, control the pH value of the reaction process to 1.8, leaching with mechanical stirring (220rad / min) at 40°C for 6h, and control the pH of the solution at the end of the reaction=1.5; filter to obtain the rare earth and aluminum-containing pickling solution and silicon-rich slag. The leaching rates of aluminum, rare earth and silicon (calculated as oxides) in the acid leaching solution containing rare earth and aluminum were 77.2%, 91.5% and 4.5%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com