High-damp silica gel cement, composite material containing high-damp silica gel cement and preparation methods and application thereof

A composite material and high damping technology, applied in the field of silicone rubber materials, can solve the problems of unsatisfactory, unsatisfactory material durability and practicability, and the maximum loss factor is not too high, and achieves the effect of simple processing method and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) First put 100 parts of phenyl hydroxy silicone oil with 15% phenyl content and 15 parts of boric acid in a kneader at a temperature of 180°C to prepare silica gel clay containing boron hydroxyl and phenyl groups, and then add 3 parts Hybridization of arachidic acid to prepare silica gel with low cross-linking degree;

[0046] 2) Mix 100 parts of low-crosslinking silica gel clay, 50 parts of lead zirconate titanate powder, and 15 parts of acetylene carbon black powder through an open mill to prepare high-damping silica gel clay.

[0047] The maximum loss factor of the high damping silica gel is 1.43, and the temperature range where the loss factor is greater than 0.3 reaches 88°C.

Embodiment 2

[0049] 1) First put 100 parts of phenyl hydroxy silicone oil with a phenyl content of 25% and 15 parts of boric acid in a kneader and react at a temperature of 180°C to prepare silica gel containing boron hydroxyl and phenyl groups, and then add 3 parts Hybridization of arachidic acid to prepare silica gel with low cross-linking degree;

[0050] 2) Mix 100 parts of low-crosslinking silica gel clay, 50 parts of lead zirconate titanate powder, and 15 parts of acetylene carbon black powder through an open mill to prepare high-damping silica gel clay.

[0051] The maximum loss factor of the high damping silica gel is 1.56, and the temperature range where the loss factor is greater than 0.3 reaches 92°C.

Embodiment 3

[0053] 1) First put 100 parts of phenyl hydroxy silicone oil with 35% phenyl content and 15 parts of boric acid in a kneader at a temperature of 180°C to prepare silica gel clay containing boron hydroxyl and phenyl groups, and then add 3 parts Hybridization of arachidic acid to prepare silica gel with low cross-linking degree;

[0054] 2) Mix 100 parts of low-crosslinking silica gel clay, 50 parts of lead zirconate titanate powder, and 15 parts of acetylene carbon black powder through an open mill to prepare high-damping silica gel clay.

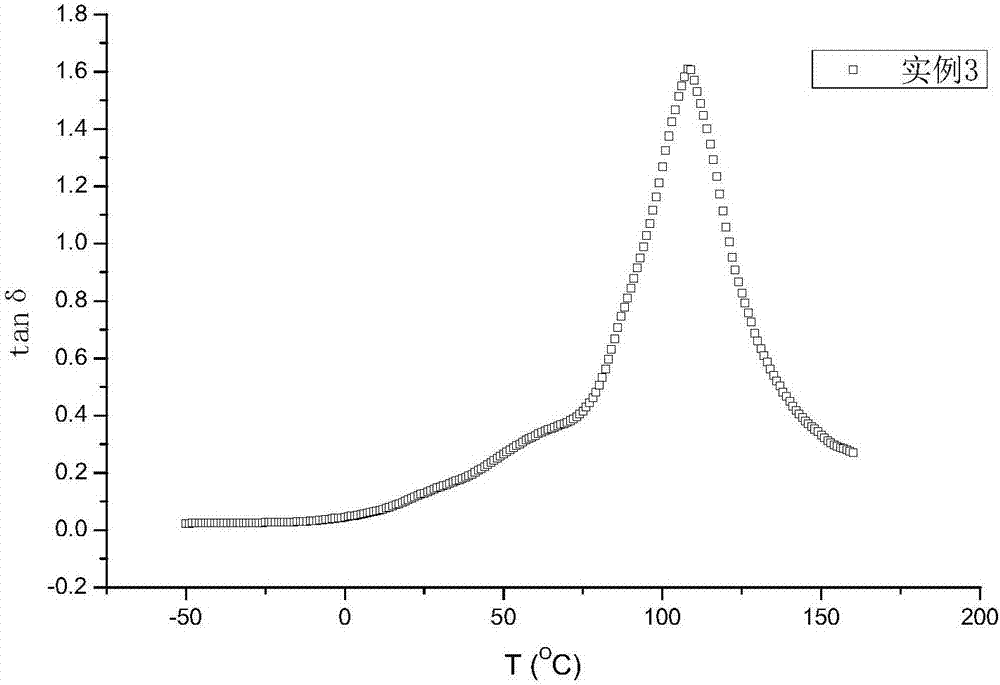

[0055] The loss factor-temperature curve of high damping silica gel is as follows figure 1 As shown, the maximum loss factor is 1.61, and the temperature range where the loss factor is greater than 0.3 reaches 98°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com