Method for preparing graphene/carbon nanotube/carbon nanofiber membrane ternary composite capacitive demineralization electrode

A technology of carbon nanofibers and carbon nanotubes, which is applied in the field of electricity, can solve the problems of poor desalination effect of capacitor desalination electrode materials, and achieve the effects of significant technological progress, good conductivity, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

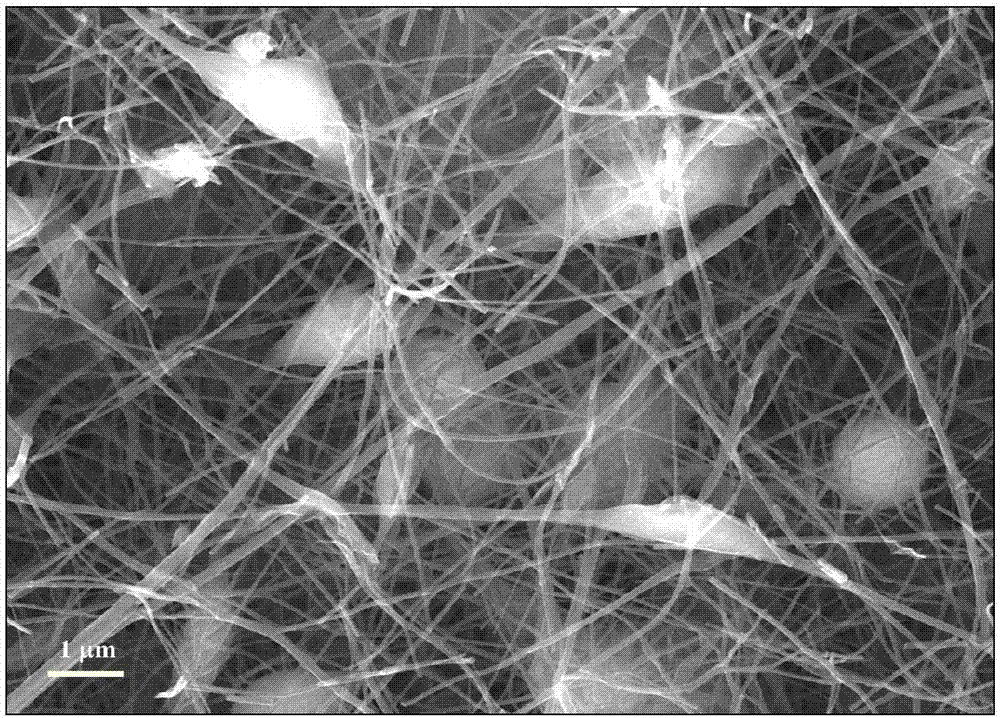

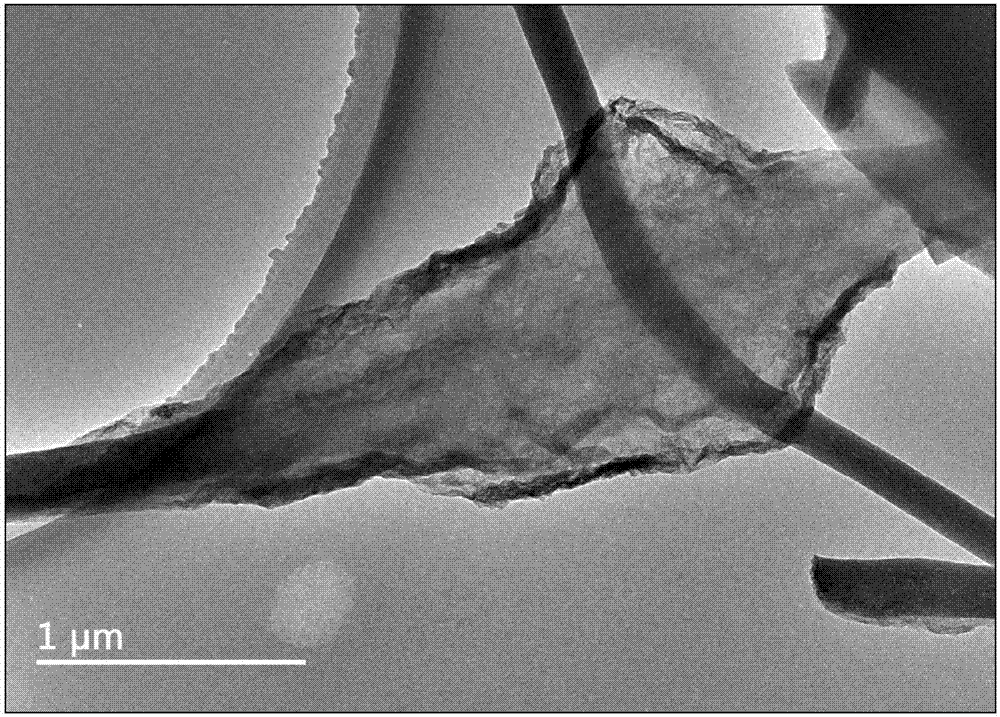

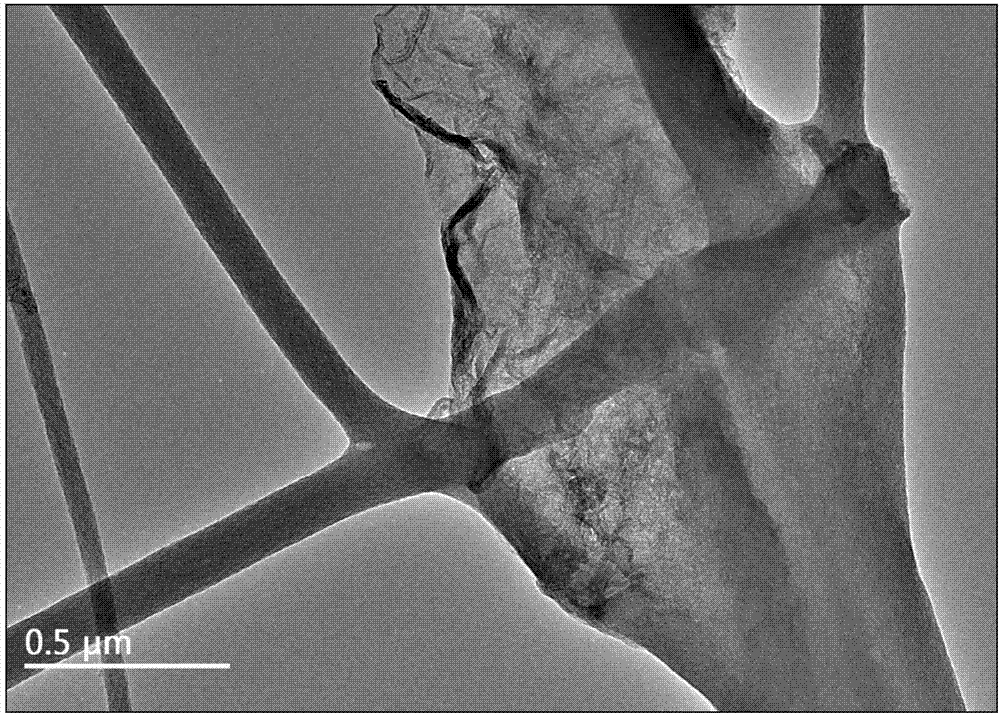

Embodiment 1

[0024] 1 g of polyacrylonitrile was dissolved in 9 g of N,N-dimethylformamide solution to prepare a 10 wt% polyacrylonitrile solution. Add 50 mg of graphene oxide and purified carbon nanotubes (2.5 mg) to the polyacrylonitrile solution, the mass ratio of graphene oxide to carbon nanotubes is 1:0.05, and mix well by ultrasonic. The solution was continuously stirred at 60° C. for 6-8 hours to obtain a graphene oxide / carbon nanotube / polyacrylonitrile dope. Using the electrospinning technique, put the graphene oxide / carbon nanotube / polyacrylonitrile dope into the syringe. Then, with a syringe pump at 18kV at 1.0mL h -1 Electrospinning was performed at a constant flow rate. Collect the electrospun fibers on grounded aluminum foil. Wherein, the distance between the grounded aluminum foil collecting plate and the needle is 15 cm. The collected fiber papers were then vacuum-dried overnight and stabilized at 250 °C for 2 h in air at a heating rate of 1 °C / min to obtain preoxidized ...

Embodiment 2

[0026] 1 g of polyacrylonitrile was dissolved in 9 g of N,N-dimethylformamide solution to prepare a 10 wt% polyacrylonitrile solution. Add 50 mg of graphene oxide and purified carbon nanotubes (5 mg) to the polyacrylonitrile solution, the mass ratio of graphene oxide to carbon nanotubes is 1:0.1, and mix evenly by ultrasonic. The solution was continuously stirred at 60° C. for a certain period of time to obtain a graphene oxide / carbon nanotube / polyacrylonitrile dope. Using the electrospinning technique, put the graphene oxide / carbon nanotube / polyacrylonitrile dope into the syringe. Then, with a syringe pump at 18kV at 1.0mL h -1Electrospinning was performed at a constant flow rate. Collect the electrospun fibers on grounded aluminum foil. Wherein, the distance between the grounded aluminum foil collecting plate and the needle is 15 cm. The collected fiber papers were then vacuum-dried overnight and stabilized at 250 °C for 2 h in air at a heating rate of 1 °C / min to obtain...

Embodiment 3

[0028] 1 g of polyacrylonitrile was dissolved in 9 g of N,N-dimethylformamide solution to prepare a 10 wt% polyacrylonitrile solution. Graphene oxide and purified carbon nanotubes were added to the polyacrylonitrile solution, the mass ratio of graphene oxide to carbon nanotubes was 1:0.15, and ultrasonically mixed evenly. The solution was continuously stirred at 60° C. for a certain period of time to obtain a graphene oxide / carbon nanotube / polyacrylonitrile dope. Using the electrospinning technique, put the graphene oxide / carbon nanotube / polyacrylonitrile dope into the syringe. Then, with a syringe pump at 18kV at 1.0mL h -1 Electrospinning was performed at a constant flow rate. Collect the electrospun fibers on grounded aluminum foil. Wherein, the distance between the grounded aluminum foil collecting plate and the needle is 15 cm. The collected fiber papers were then vacuum-dried overnight and stabilized at 250 °C for 2 h in air at a heating rate of 1 °C / min to obtain pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com