Ring formation process method for large vacuum chamber fan-shaped section with double-layer thin-wall structure and D-shaped cross section

A process method and sector-shaped technology, which are applied in the field of magnetic confinement controlled thermonuclear fusion vacuum equipment manufacturing to achieve the effect of ensuring dimensional consistency and solving shrinkage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The technical solutions of the present invention will be further described in detail below through specific examples.

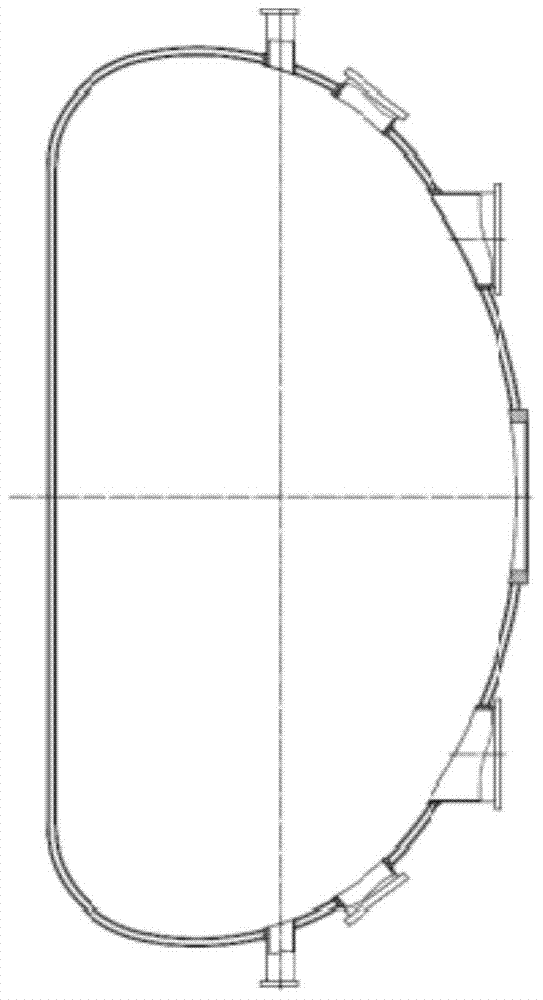

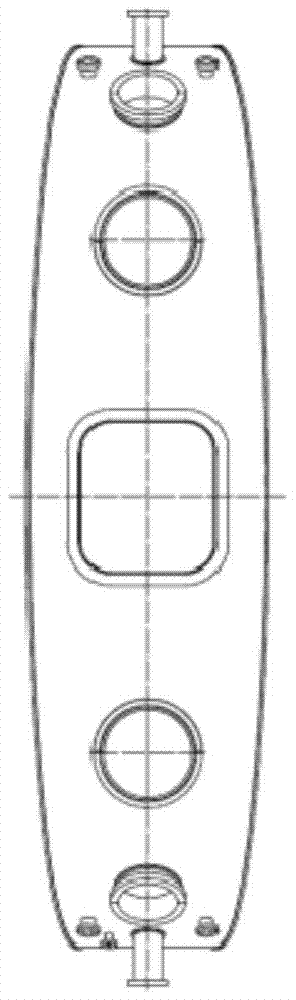

[0052] The present invention is a large-scale double-layer thin-walled D-shaped cross-section vacuum chamber fan-shaped segment ring-forming process, and 20 fan-shaped segments are connected in sequence to form a vacuum ring, such as figure 1 with figure 2 As shown, the cross-section of each sector is D-shaped, and the central angle between the two sides is 18°; each sector is a double-layer hyperboloid thin-walled space structure, which is welded by the inner shell, channel steel and outer shell It consists of ①straight segment, ②R375 segment with two vertically symmetrical radii of 375mm and a central angle of 78.7°, ③R895 segment with two vertically symmetrical radii of 895mm and a central angle of 55.56°, ④radius of 1910mm , the four parts of the R1910 segment with a central angle of 70.68°; the upper and lower ends of the straight segment are tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com