Pipeline outer wall bionic groove surface machining device and machining method thereof

A technology for processing the outer wall and surface of a pipeline, which is used in positioning devices, driving devices, feeding devices, etc., to solve problems such as increased pipeline resistance, excessive pipeline yield, and decreased efficiency, avoiding bending deformation and torsional deformation, strong movement ability and Effects of stability, good centering and positioning functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

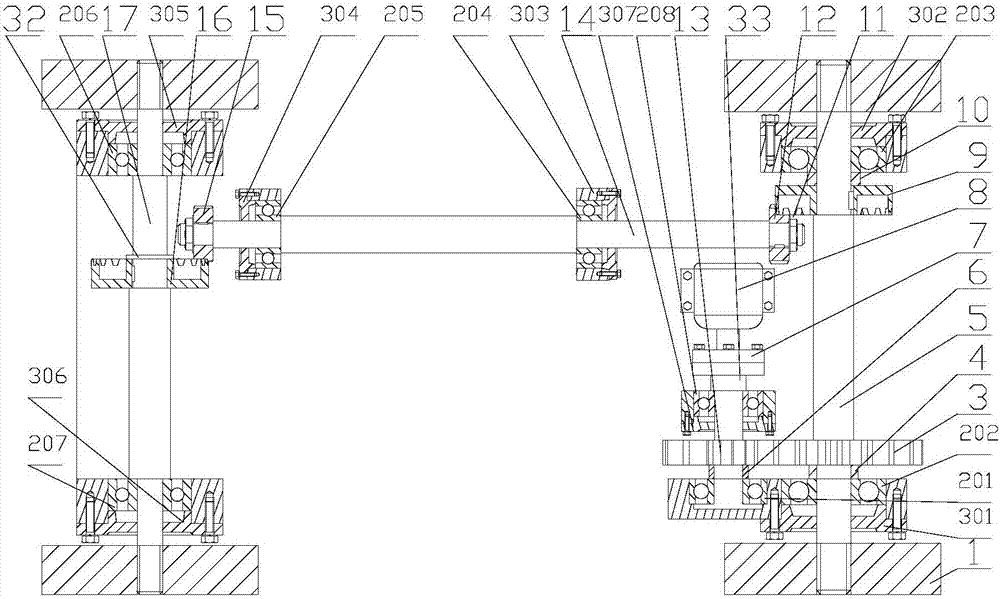

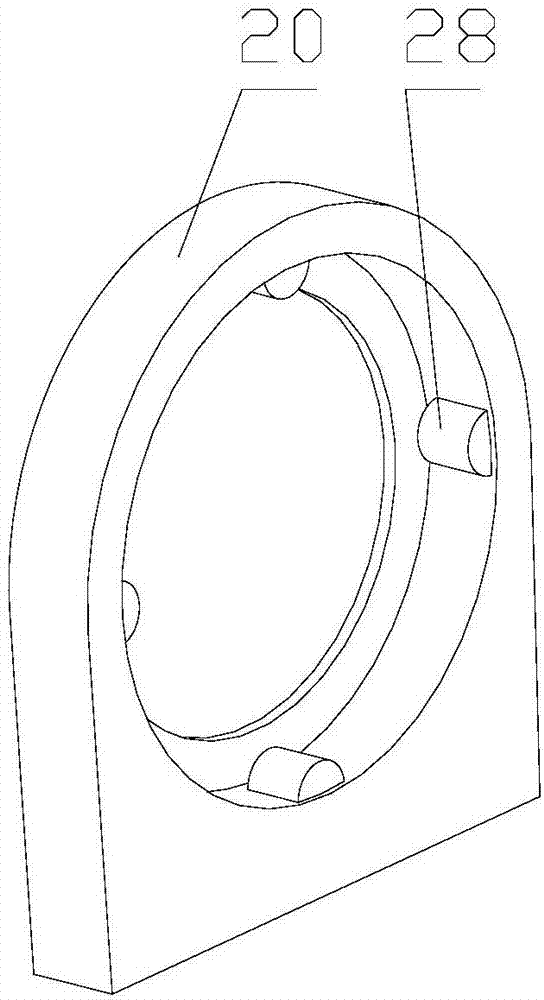

[0027] Embodiment 1 A biomimetic groove surface processing device for the outer wall of a pipe according to the present invention includes a driving mechanism for providing a driving force, a support seat 18 for connecting the driving mechanism and supporting the processing mechanism, and used for processing the outer wall of the pipe. The processing mechanism and controller of the bionic groove, the first support platform 19 and the second support platform 20 are installed above the support seat 18, and the first support platform 19 and the second support platform 20 are arranged coaxially and symmetrically on both sides of the support seat 18. end, and there is an installation area for installing part of the workpiece of the processing mechanism between the two; the drive mechanism is installed under the support base 18; the clamp of the processing mechanism is installed between the first support platform 19 and the second support platform 20 between; the driving mechanism an...

Embodiment 2

[0037] Embodiment 2 According to the processing method of the bionic groove surface processing device on the outer wall of a pipeline described in Embodiment 1, the processing method comprises the following steps:

[0038] 1) First, support the pipeline to a suitable height through the auxiliary device, just to make the central axis of the pipeline coincide with the central axis of the processing mechanism;

[0039] 2) Start the driving motor 8 to make the first transmission gear 13 mesh with the second transmission gear 3 to rotate, and drive the input shaft 5 to rotate, so that the third transmission gear 9 installed on the input shaft 5 and the third transmission gear 9 installed on the connecting shaft 14 The four transmission gears 12 mesh with each other and rotate, and then the fifth transmission gear 15 installed on the connecting shaft 14 is engaged with the sixth transmission gear 16 installed on the transmission shaft 17 to rotate, so that the transmission gears inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com