Black tea processing technology

A processing technology, black tea technology, applied in the field of black tea processing technology, can solve the problem that it is difficult to guarantee the aroma and taste of black tea, and achieve the effect of promoting enzyme activation and maintaining freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

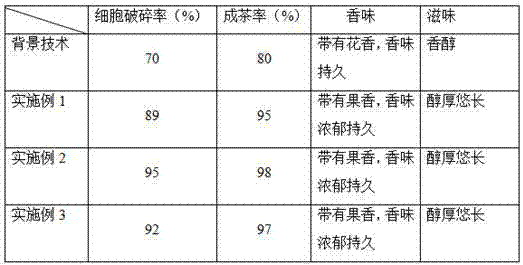

Examples

Embodiment 1

[0018] Embodiment 1: the processing technology of black tea, comprises 6 operations of leaf selection and airing process, withering process, vacuum microwave treatment process, rolling process, fermentation process and drying process, concrete operations are as follows:

[0019] a. Leaf selection and drying process: pick fresh tea leaves with one bud and two leaves or one bud and three leaves on the big tree tea in a green tea garden above 800 meters above sea level, and place the fresh leaves in a rotating drying tray. The thickness of the spread leaves is 2~3cm, the temperature is 20~26℃, the light intensity is 30000LUX in the outdoor sunlight for 1h, the spreader is rotated every 10min, each time takes 2min, and the tea is thinned and beaten Disperse, so that it can dissipate moisture as soon as possible;

[0020] b. Withering process: place the tea leaves that have been selected and aired in the withering tank for hot air withering, the temperature of the hot air is 30°C, ...

Embodiment 2

[0025] Embodiment 2: the processing technology of black tea, comprises 6 operations of leaf selection and airing process, withering process, vacuum microwave treatment process, rolling process, fermentation process and drying process, concrete operations are as follows:

[0026] a. Leaf selection and drying process: pick fresh tea leaves with one bud and two leaves or one bud and three leaves on the big tree tea in a green tea garden above 800 meters above sea level, and place the fresh leaves in a rotating drying tray. The thickness of the spread leaves is 2~3cm, the temperature is 20~26℃, the light intensity is 40000LUX in the outdoor sunlight for 1h, and the spreader is rotated every 8min, and each time takes 1.5min to spread the tea leaves Break it up so that it can distribute moisture as soon as possible;

[0027] b. Withering process: place the tea leaves that have been selected and aired in the withering tank for hot air withering, the temperature of the hot air is 40°C...

Embodiment 3

[0032]Embodiment 3: the processing technology of black tea, comprises 6 operations of leaf selection and airing process, withering process, vacuum microwave treatment process, rolling process, fermentation process and drying process, concrete operations are as follows:

[0033] a. Leaf selection and drying process: pick fresh tea leaves with one bud and two leaves or one bud and three leaves on the big tree tea in a green tea garden above 800 meters above sea level, and place the fresh leaves in a rotating drying tray. The thickness of the spread leaves is 2~3cm, the temperature is 20~26℃, the light intensity is 50000LUX in the outdoor sunlight for 0.5h, and the spreader is rotated every 8min, and each time takes 1min to spread the tea leaves Break it up so that it can distribute moisture as soon as possible;

[0034] b. Withering process: place the tea leaves that have been selected and spread out in the withering tank for hot air withering, the hot air temperature is 50 ° C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com