Automatic meat perforation device

A technology of automatic threading and cutting device, applied in meat processing, meat processing equipment, meat cutting/trimming, etc., can solve the problems of low efficiency, energy consumption, easy injury, etc., achieve low friction loss, high transmission efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

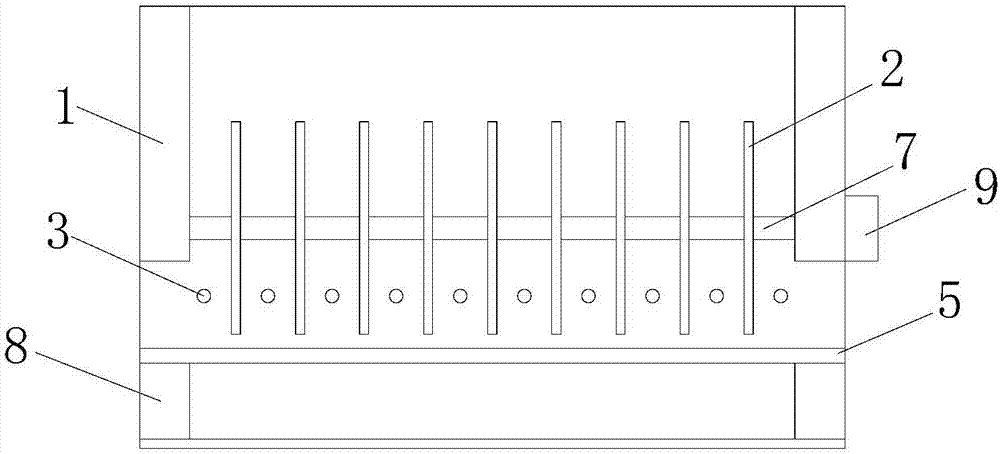

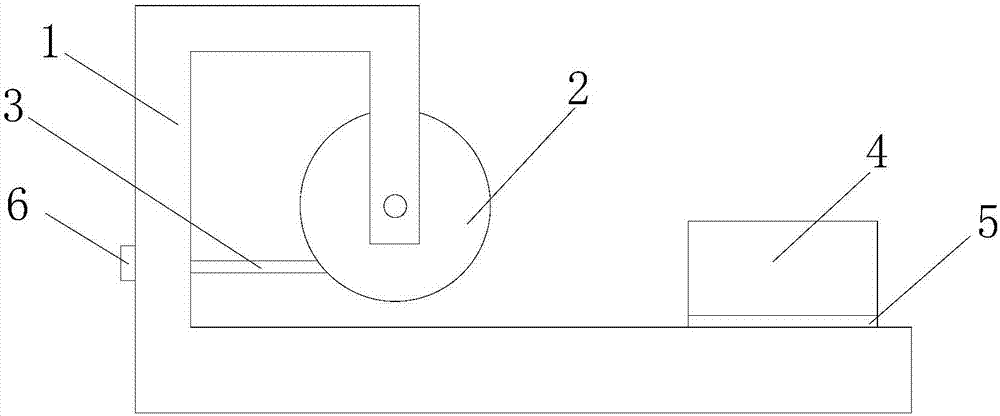

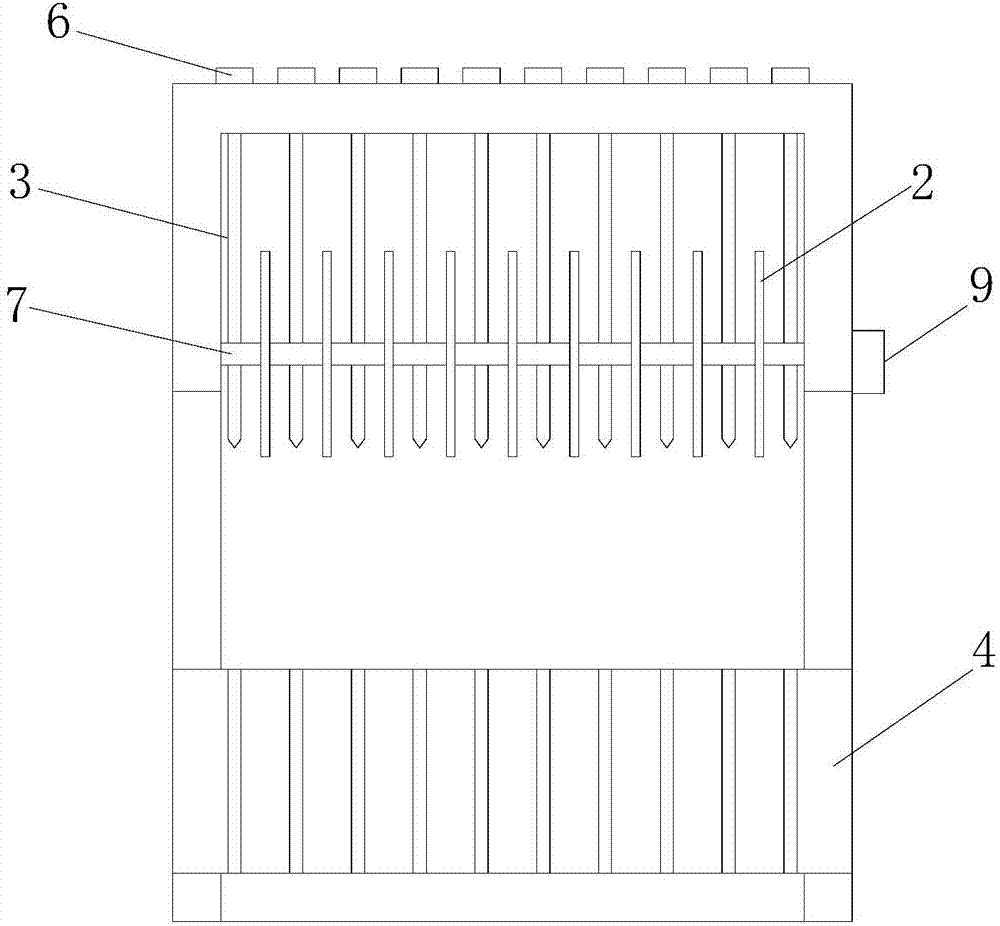

[0026] Such as figure 1 , figure 2 and image 3 As shown, it includes a frame 1, a cutting device, a drilling device and a material delivery device. The frame 1 includes a base plate, a vertical plate and a cutting knife frame. The bottom of the vertical plate is connected to the base plate, and the cutting tool frame is connected to the top of the vertical plate. The cutting device includes a cutting motor 9, a rotating shaft 7 and some circular cutters 2, and several circular cutters 2 are connected in a row by the rotating shaft 7 to form a cutting blade group, and the cutting blade group is rotatably connected with the cutting tool holder, and the cutting motor 9 output shaft It is connected with the rotating shaft 7 in transmission; the drilling device includes several drills 3 and drilling motors 6, the drilling 3 is connected with the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com