Semiconductor circuit arrangement and assembly method with pressurized gel

A circuit layout and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as cracking, non-assemblable parts, and inability to use thermal interface materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

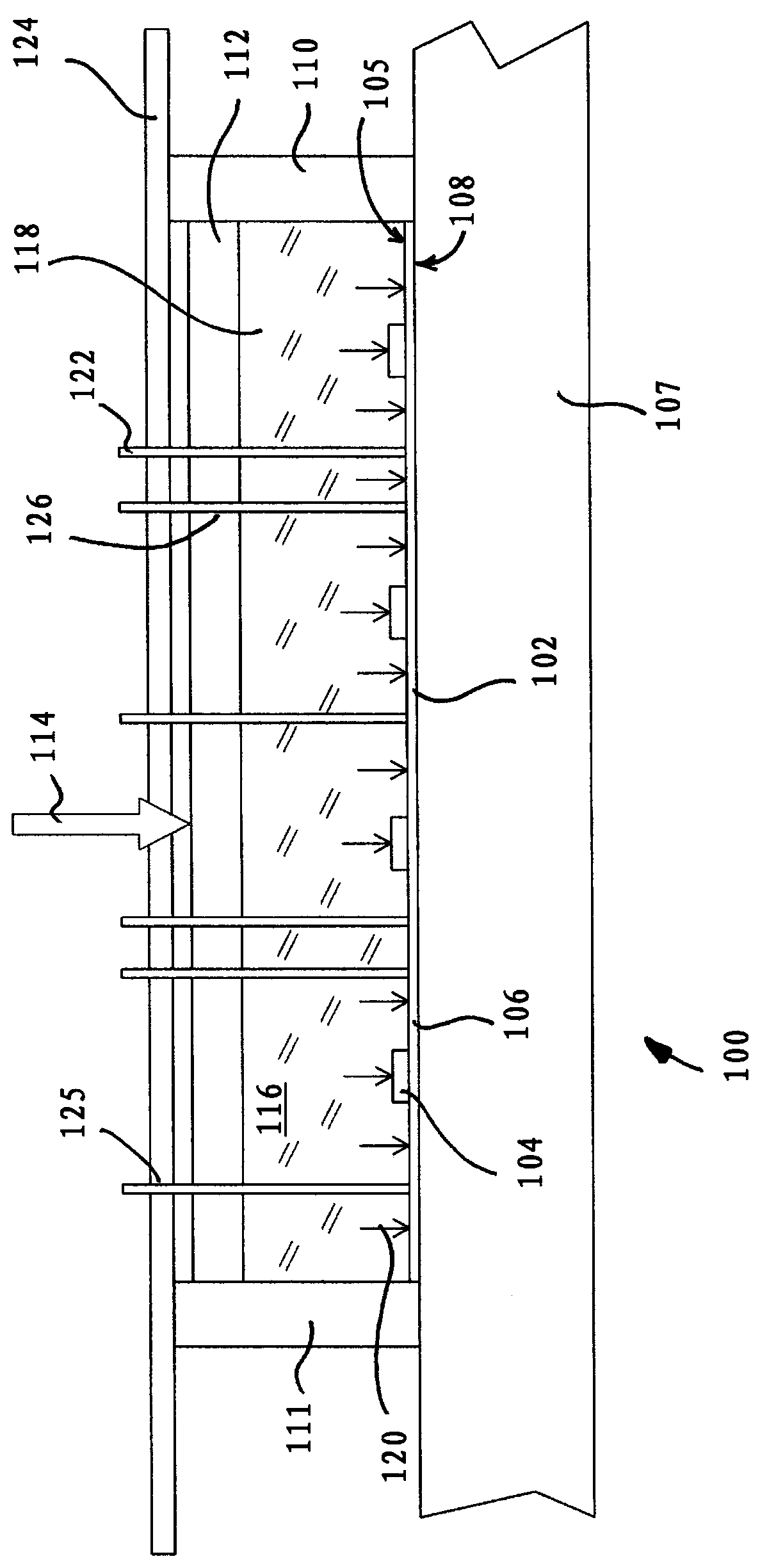

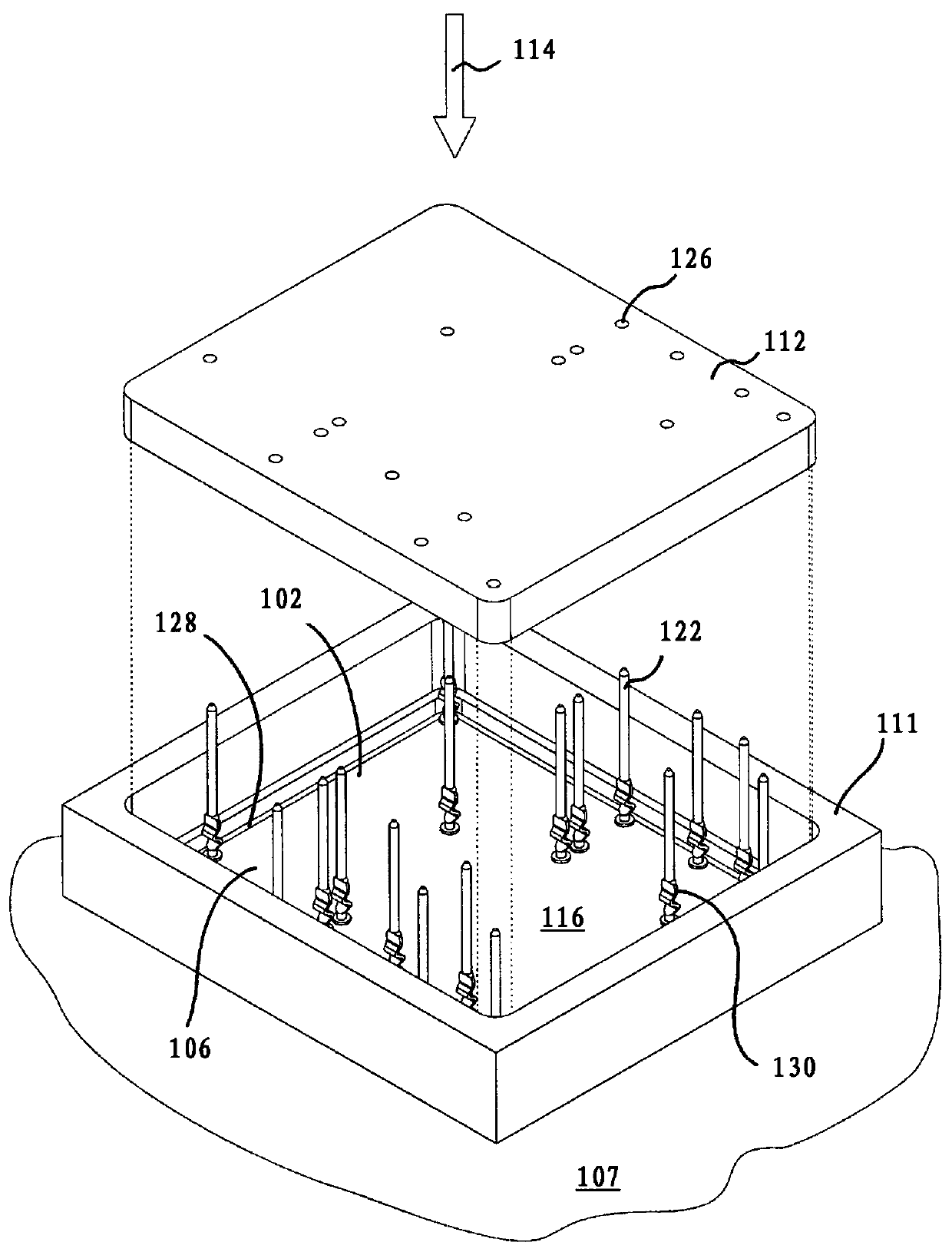

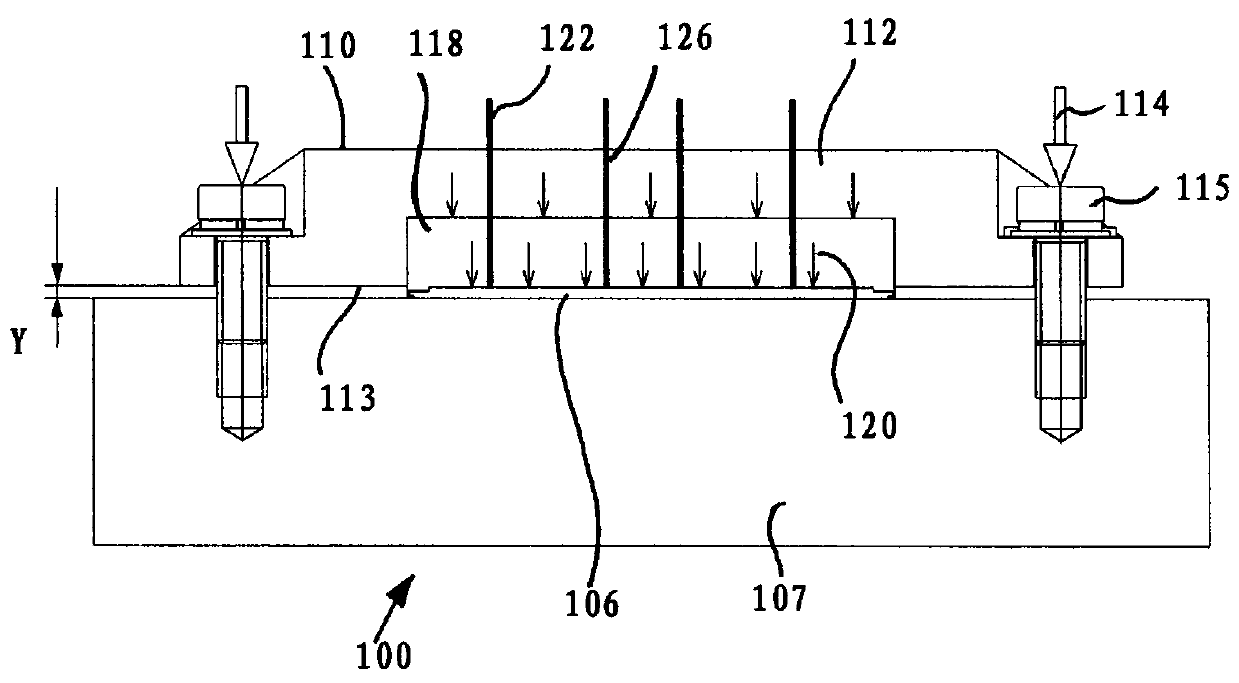

[0060] The invention will now be further described with reference to the accompanying drawings, first with reference to figure 1 . figure 1 A schematic cross-sectional view of a semiconductor circuit arrangement 100 according to the invention is shown.

[0061] According to the present invention, the power semiconductor module 102 includes a plurality of semiconductor die 104 mounted on a first surface 105 of a direct copper bonding (DCB) substrate 106 . Via the opposite second surface 108 the DCB substrate 106 is attached to the base plate 107 . Base plate 107 may be made of metal, such as aluminum or copper, and may be connected to a heat sink. alternatively, figure 1 The bottom plate 107 shown may itself represent a heat sink.

[0062] The power semiconductor module 102 is surrounded by a housing 110 , which is made, for example, of a plastic material known in the art. According to the present invention, the housing 110 is formed by a frame 111 and a cover 112 . Cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com