Experimental system for interaction between fuel and coolant inside sodium-cooled fast reactor molten fuel tank

A sodium-cooled fast reactor and experimental system technology, applied in educational appliances, instruments, teaching models, etc., can solve problems such as recritical danger, and achieve the effect of improving safety evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

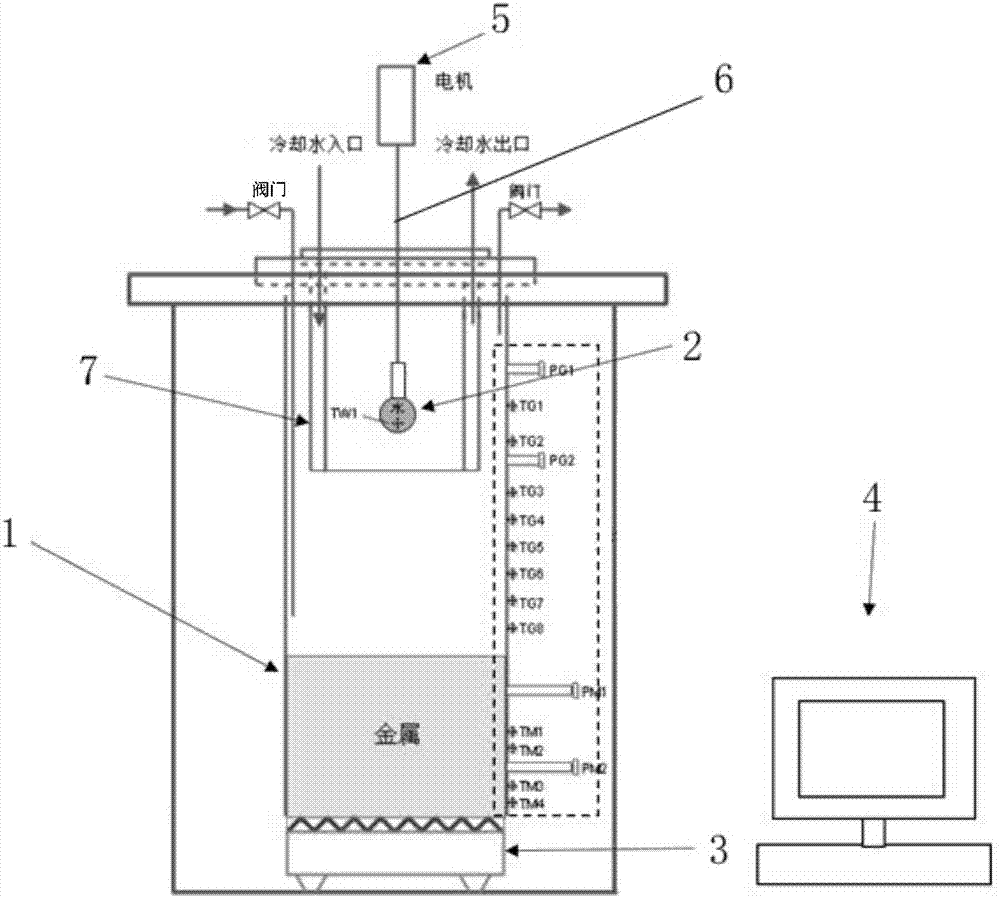

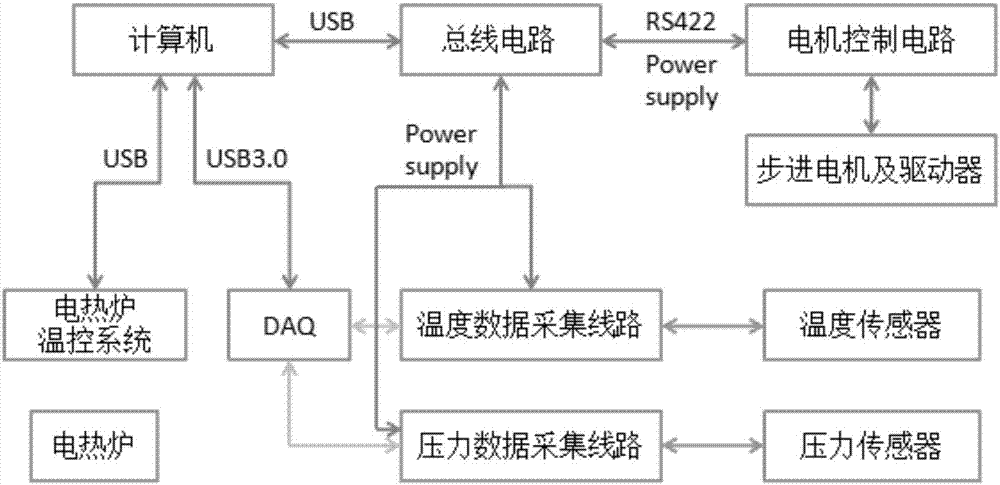

[0014] Such as figure 1 , 2 As shown, an experimental system for the interaction between fuel and coolant in a sodium-cooled fast reactor molten fuel pool provided by the present invention includes a reaction vessel 1, a coolant vessel 2, a drive module, a heating module 3, a data acquisition module and a control terminal 4; wherein the heating module 3 is used to heat the reaction container 1; the coolant container 2 is arranged above the reaction container 1, and the coolant container 2 is connected to the driving end of the drive module, and the drive module is used to turn the coolant container 2 to the transported down to the reaction container 1; the data collection module is set in the reaction container 1; the heating module 3, the drive module, and the data collection module are electrically connected to the control terminal 4.

[0015] In this embodiment, the control terminal 4 is a computer.

[0016] The working process of the experimental system is as follows: th...

Embodiment 2

[0018] On the basis of Embodiment 1, this embodiment further optimizes the specific structure of the experimental system, specifically:

[0019] The reaction container 1 is installed on a support; the support is provided with a screw rod installation position and a motor installation position. Wherein the drive module includes a motor 5, a motor control circuit and a screw mandrel 6, the screw mandrel 6 is arranged vertically downward, the motor 5 and the screw mandrel 6 are connected in transmission, the motor 5 is electrically connected with the control terminal 4 through the motor control circuit, and the screw mandrel 6. The motor 5 is respectively installed on the screw rod installation position and the motor installation position.

[0020] During specific implementation, the control terminal 4 controls the rotation of the motor 5 by controlling the motor control circuit, and then adjusts the movement of the screw rod 6, thereby driving the movement of the coolant contain...

Embodiment 3

[0026] In this embodiment, on the basis of Example 2, the specific structure of the reaction generating vessel 1 is further optimized. Specifically, the reaction generating vessel 1 is made of stainless steel, which is columnar as a whole, and a temperature transmitter is arranged inside it. The installation port and the pressure transmitter installation port, as well as a pressure relief valve installation port and a low melting point alloy discharge port, during the experiment, the reaction vessel 1 can withstand a high temperature within 1000 degrees Celsius and an internal pressure of at least 2MPa.

[0027] In the specific implementation process, the upper part of the reaction generating container 1 is provided with a heat insulating cylinder 7, and the heat insulating cylinder 7 is suspended in the reaction generating container 1, and the top end of the heat insulating cylinder 7 is provided with an end cover, so A group of gas inlet and outlet and coolant container 2 inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com