Jacking pipe close in butt joint and with escape pipes

A technology of escape pipe and pipe jacking, which is applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc. It can solve the problems of pipe jacking without escape pipes, etc., and achieve good sealing, fast connection, and convenience crawling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

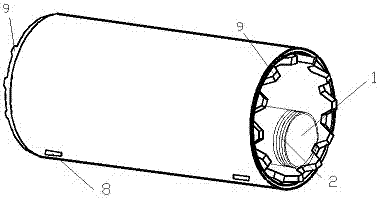

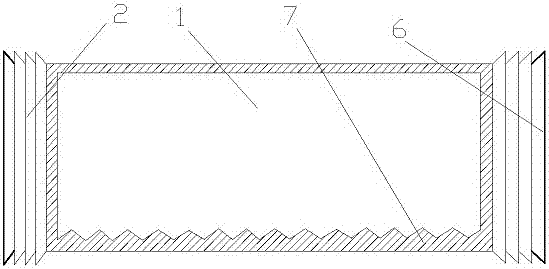

[0020] A jacking pipe that is tightly butted and has an escape pipe, which is formed by connecting more than two jacking pipes, and two or more protruding teeth 9 arranged at intervals are respectively arranged on the two ends of the jacking pipe, connecting two The jacking pipes are meshed and docked by convex teeth 9. An escape pipe 1 is installed on the inner pipe wall of the jacking pipe. The two ends of the escape pipe 1 are provided with corrugated joints 2. The corrugated joints 2 of the adjacent escape pipe 1 pass through the connecting ring 3. interconnected.

[0021] During on-site construction, it is necessary to dock the pipe jacking of the latter section with the pipe jacking of the previous section, install the escape pipe 1 on the inner pipe wall of the pipe jacking, and the two sections of pipe jacking can quickly complete the docking through the convex teeth 9, and Due to the position limitation of the protruding teeth 9, the escape pipe 1 can also be docked q...

Embodiment 2

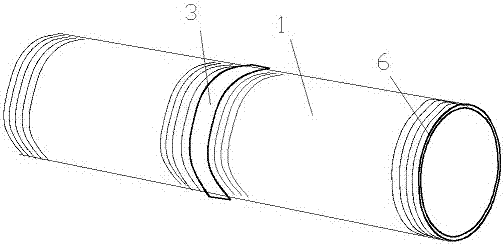

[0023] A jacking pipe that is tightly butted and has an escape pipe, which is formed by connecting more than two jacking pipes, and two or more protruding teeth 9 arranged at intervals are respectively arranged on the two ends of the jacking pipe, connecting two The jacking pipes are meshed and docked by convex teeth 9. An escape pipe 1 is installed on the inner pipe wall of the jacking pipe. The two ends of the escape pipe 1 are provided with corrugated joints 2. The corrugated joints 2 of the adjacent escape pipe 1 pass through the connecting ring 3. interconnected. The two ends of the connecting ring 3 are respectively provided with annular grooves 4 , the end surfaces of the corrugated joints 2 are inserted into the annular grooves 4 , and the corrugated joints 2 and the connecting ring 3 are respectively provided with mutually matching connecting fasteners. The end face of the corrugated joint 2 is inserted into the annular groove 4, and then reinforced with connecting fa...

Embodiment 3

[0026] A jacking pipe that is tightly butted and has an escape pipe, which is formed by connecting more than two jacking pipes, and two or more protruding teeth 9 arranged at intervals are respectively arranged on the two ends of the jacking pipe, connecting two The jacking pipes are meshed and docked by convex teeth 9. An escape pipe 1 is installed on the inner pipe wall of the jacking pipe. The two ends of the escape pipe 1 are provided with corrugated joints 2. The corrugated joints 2 of the adjacent escape pipe 1 pass through the connecting ring 3. interconnected. The two ends of the connecting ring 3 are respectively provided with annular grooves 4 , the end surfaces of the corrugated joints 2 are inserted into the annular grooves 4 , and the corrugated joints 2 and the connecting ring 3 are respectively provided with mutually matching connecting fasteners. The end face of the corrugated joint 2 is inserted into the annular groove 4, and then reinforced with connecting fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com