Safety net and belt comprehensive test system

A comprehensive test and safety net technology, applied in the direction of impact test, machine/structural component test, measuring device, etc., can solve problems such as rollover or rollover, heavy weight of standard test objects, and affect the safety of workers to achieve protection safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The following is attached Figure 1-6 The application is described in further detail.

[0068] The embodiment of the application discloses a safety net and belt comprehensive testing system.

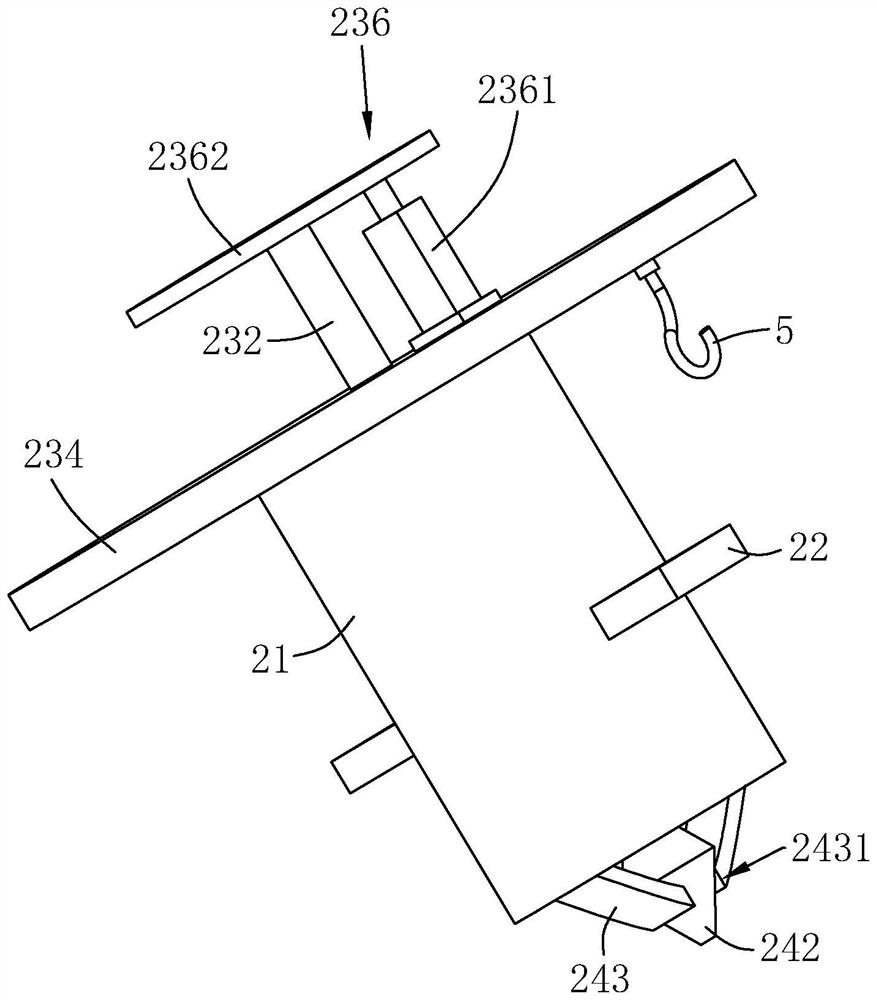

[0069] refer to figure 1 , a safety net, belt comprehensive testing system includes a frame 1, a fixing device 2 for fixing a hollow steel pipe or a standard test object with a hanging ring, a lifting device 3 for driving the fixing device 2 up and down, and a tensioning safety net The tensioning device 4, the tensioning device 4 and the lifting device 3 are all connected with the frame 1.

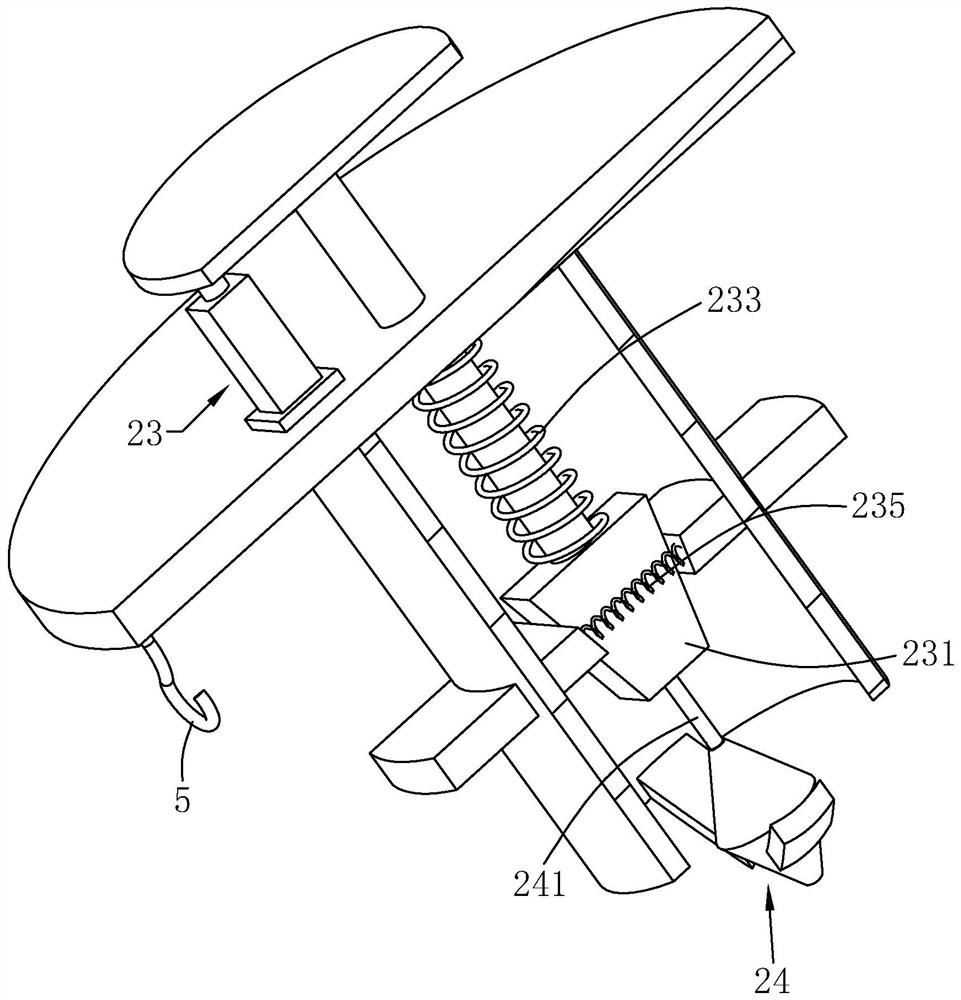

[0070] refer to figure 2 and image 3 , the fixing device 2 includes a mounting tube 21, two sliding blocks 22, a drive mechanism 23 for driving the two sliding blocks 22 to approach or move away from each other, and a fixing mechanism 24 for hanging or releasing the hanging ring; the mounting tube 21 Hollow setting, the two sliding blocks 22 are located on the same horizontal plane, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com