Steam flooding well production string and implementation method

A production pipe string and steam flooding technology, which is used in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the problem of affecting the effect of steam flooding, steam injection, rapid well temperature drop, and the inability of the production pipe string to meet continuous production. requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0027] Technical scheme of the present invention is realized in the following manner

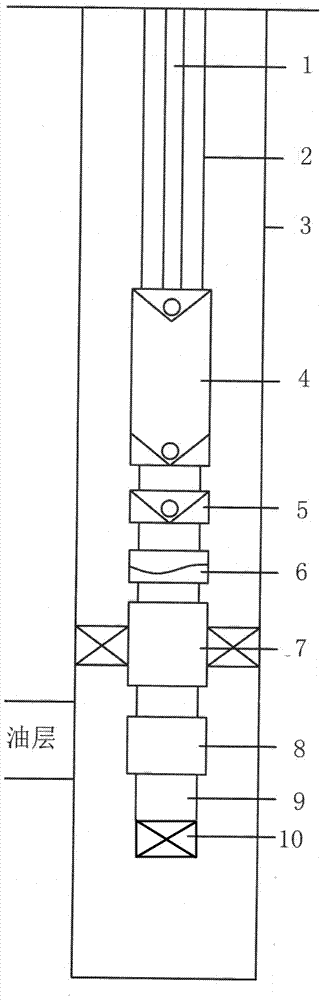

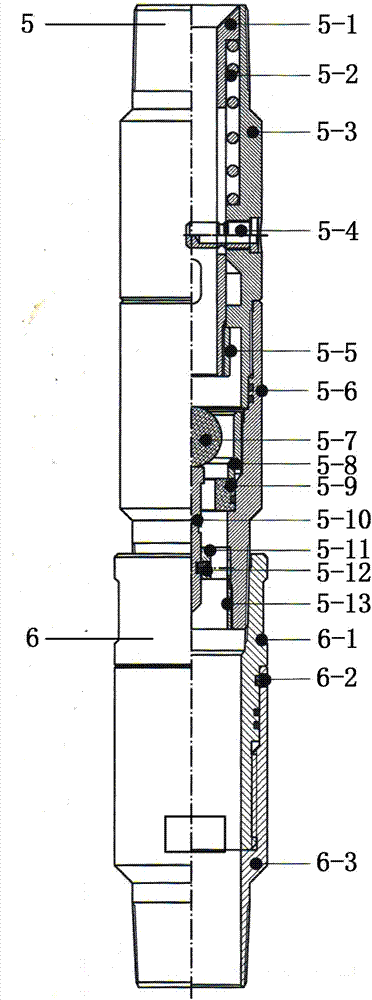

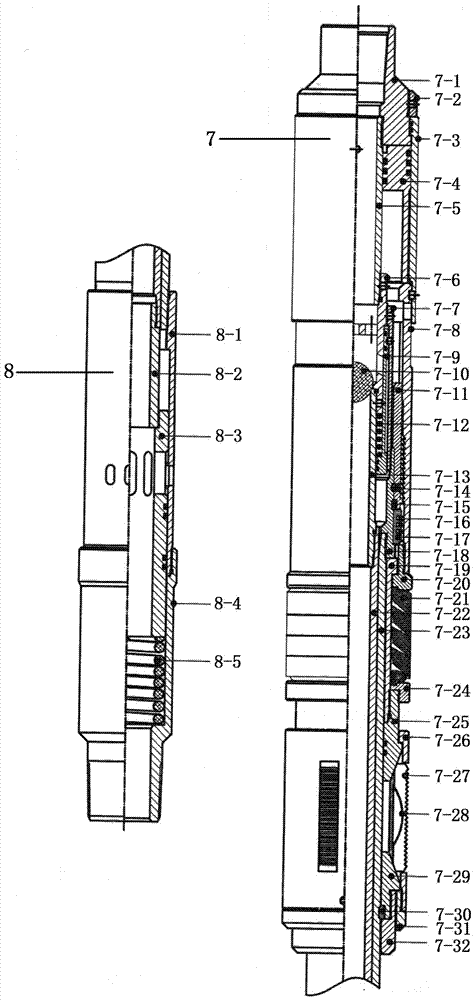

[0028] Such as figure 1 As shown, the steam flooding oil well production string of the present invention consists of sucker rod 1, tubing 2, casing 3, oil pump 4, overpressure and overflow valve 5, safety joint 6, intubation bridge plug 7, bottom valve 8, Tail pipe 9, plug 10 are formed. The oil pipe 2 is connected with the oil well pump 4 through threads, the lower part of the oil sucker rod 1 is threadedly connected with the plunger, and is lowered into the oil well pump 4 through the oil pipe 2, and the oil well pump 4 is threadedly connected with the overpressure and overflow valve 5 through the short joint of the oil pipe. The overpressure overflow valve 5 is threadedly connected with the safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com