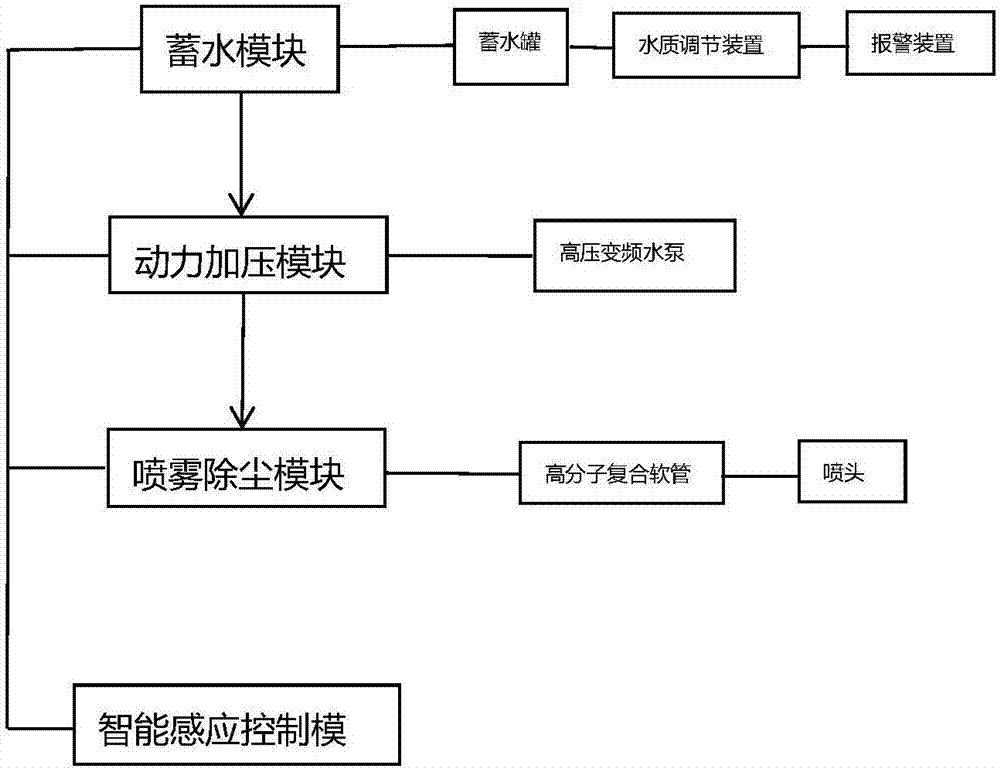

Environmental-friendly construction dedusting system with intelligent induction function

A dust removal system and intelligent technology, applied in the direction of liquid injection device, road surface cleaning, spraying device, etc., can solve the problems of damage to the on-site staff, user health, environmental quality, etc., and achieve the effect of good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: pH value sensor function detection

[0019] Three water sources of water quality were taken for testing, divided into water source A, water source B, and water source C. After testing, their pH values were 6.2, 6.9, and 8.8. The value sensor is connected to the alarm device outside the water storage tank, the liquid level probe, the pH sensor, and the alarm device are electrically connected to the input end of the PLC automatic control system, and the output end of the PLC automatic control system is electrically connected to the electric valve of the high-pressure pump inlet pipe. When the water source A and water source C are connected, the sound and light alarm in the alarm device connected to the PLC automatic control system sends out an alarm signal, and at the same time the high-pressure pump stops the pressurized water supply, and the spray nozzle is closed; while the water source B is connected, everything is normal .

Embodiment 2

[0020] Embodiment 2: Intelligent control detection of dust sensor

[0021] Set up three closed test chambers for air dust concentration, which are respectively recorded as test chamber 1 and test chamber 2. The dust concentrations in them are 30ug / m3 and 70ug / m3 respectively, and the dust sensors are inserted into test chamber 1 and test chamber 2 respectively. The dust sensor transmits the detected value of the sensor to the PLC automatic control system through the wireless transmission module, and displays the detection results as 29.98ug / m3 and 70.01ug / m3, and the PLC automatic control system will detect the value and the preset dust concentration , according to the "Ambient Air Quality Standard GB3095-2012", the concentration standard limit value of particulate matter, the particle size is less than or equal to 10um, and the first-level regulation is less than or equal to 50ug / m3. At 2 o'clock, the spray dust removal was carried out, and the spray was stopped when the humi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com