A fast single shaft seam disc machine

A stitching machine and uniaxial technology, which is applied to sewing equipment, knitting machines for connecting knitted fabrics, textiles and papermaking, etc. Balance, reduce load, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

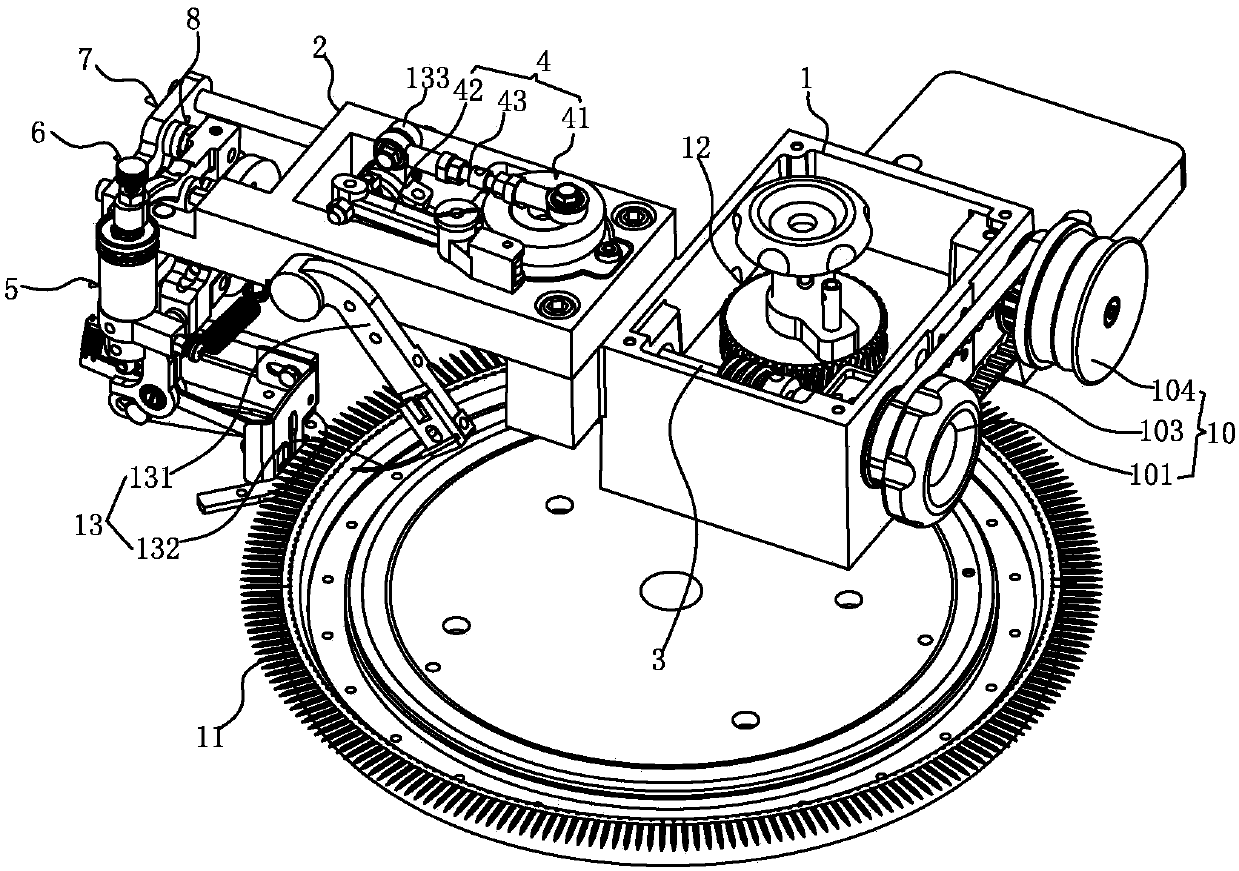

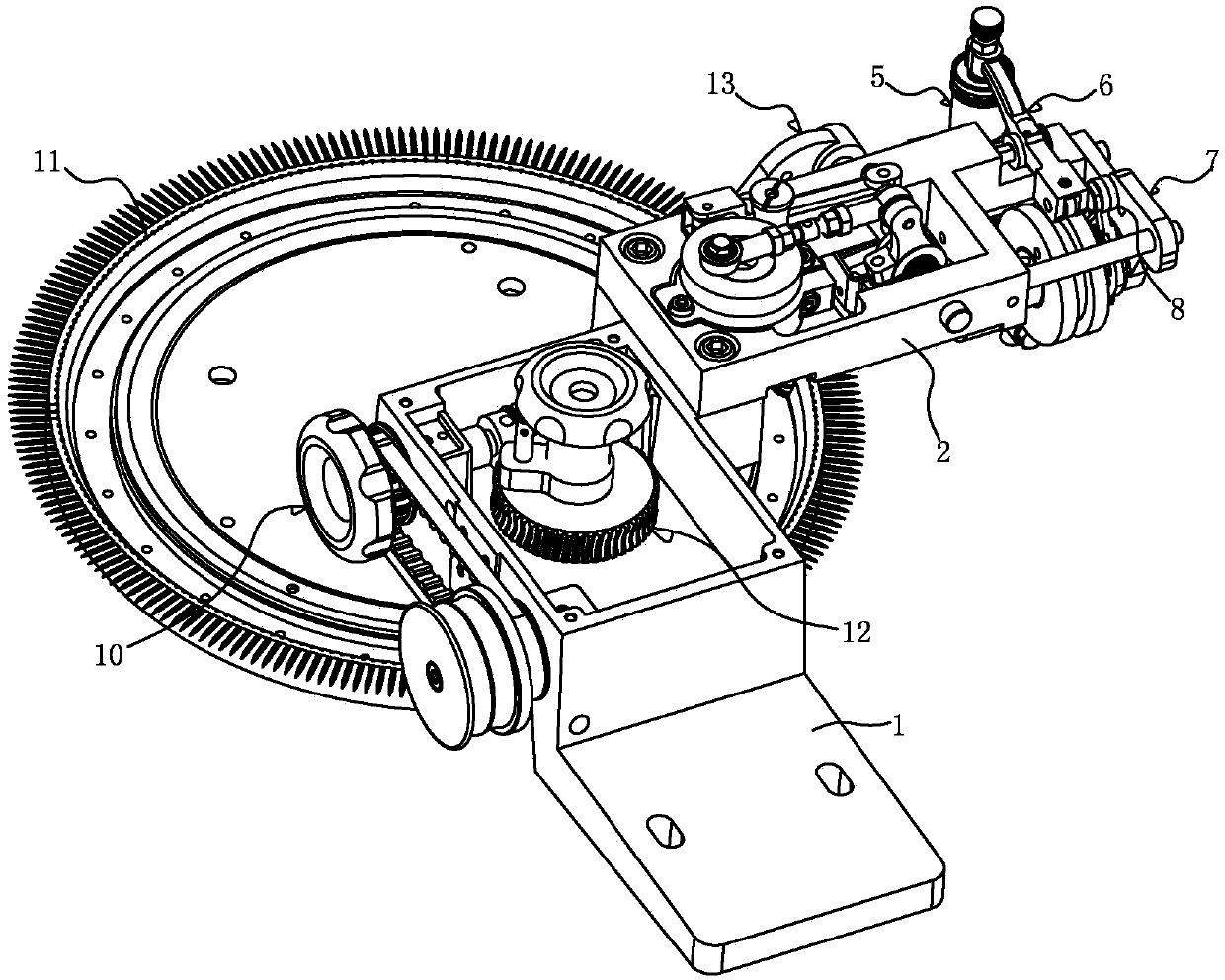

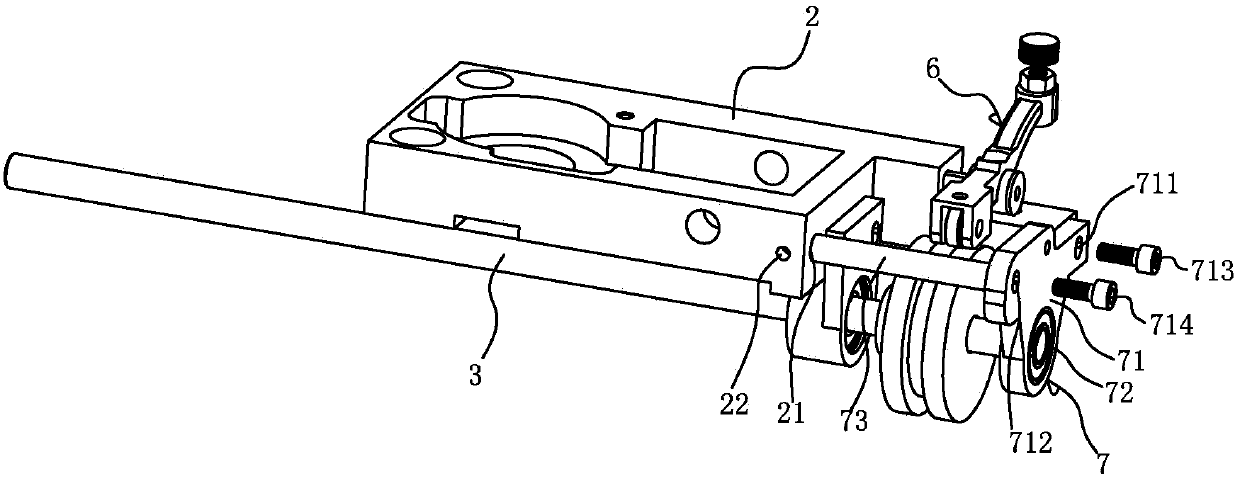

[0036] See figure 1 , 2 As shown, it is a fast single-axis disc sewing machine, which includes: a vehicle platform 1, a bracket 2 installed on the side of the vehicle platform 1, a main shaft 3 pierced through the vehicle platform 1 and the bracket 2, and installed on the vehicle platform 1. The main shaft driving device 10 on the outside and used to drive the main shaft 3 to rotate, the dial 11 installed on the lower end of the vehicle platform 1, the first driving device 12 installed in the vehicle platform 1 and linked with the main shaft 3 and used to drive the dial 11 to rotate , the hook assembly 13 installed on the outside of the bracket 2 and matched with the dial 11, the second driving device 4 installed in the bracket 2 and used to drive the hook assembly 13 to swing back and forth, left and right, and the thread take-up device 5 installed on the outside of the bracket 2, The third drive device 6 installed in the bracket 2 and used to drive the thread take-up device...

Embodiment 2

[0060] The difference between the structure of the second embodiment and the structure of the first embodiment is that: see Figure 12 As shown, the spindle driving device 10 includes a servo motor 104 installed on the side of the vehicle platform 1, and the servo motor 104 is directly connected to the spindle 3 and directly drives the spindle 3 to rotate.

[0061] The above-mentioned spindle driving device 10 has a simpler structure and is more convenient to assemble.

[0062] Except for the above, the other structures of the second embodiment are the same as those of the first embodiment, and have the same technical effect, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com