Preparation method of Cu-Mn double-doping ZnS quantum dot solution and application

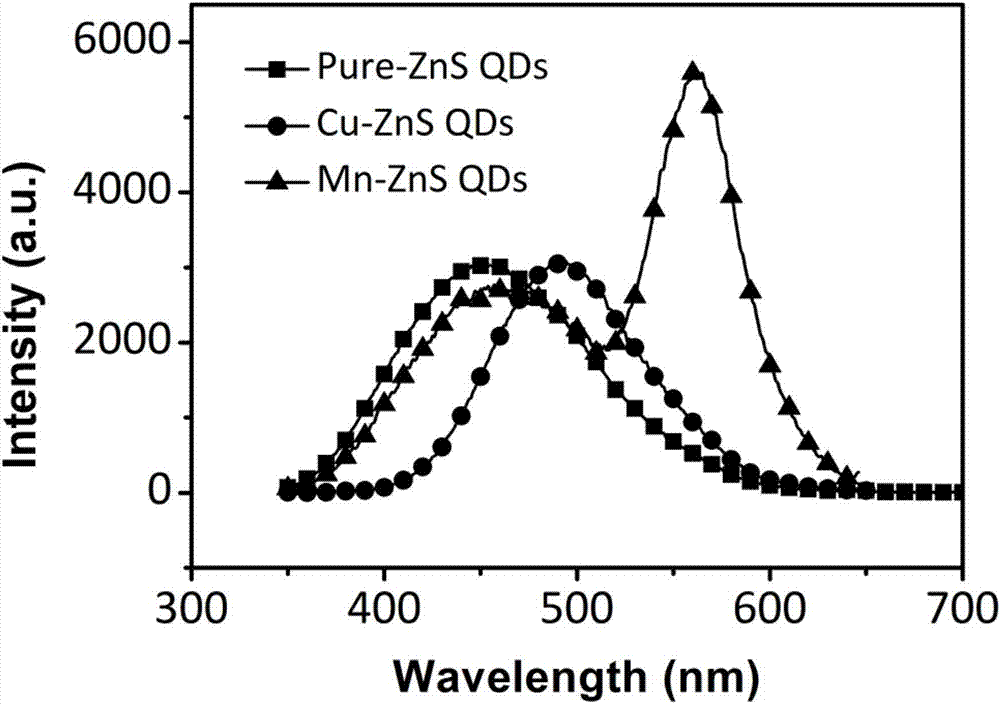

A quantum dot solution and double-doping technology, which is applied in chemical instruments and methods, fluorescence/phosphorescence, luminescent materials, etc., can solve the problem of instability of the dual emission wavelength system of fluorescent probes, and achieve stable optical properties and fluorescent optical properties. Adjustable, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of Cu-Mn double-doped ZnS quantum dot solution of the present invention comprises the following steps:

[0029] Step 1: Add Zn 2+ solution and containing Mn 2+ The solution is mixed, then the organic ligand is added and stirred evenly, and the pH value is adjusted to 10-11 with NaOH solution to obtain a mixed solution;

[0030] Step 2: Add S to the mixture obtained in Step 1 2- solution, reacting at 80-100°C for 1-2 hours to obtain a Mn-doped ZnS nanocrystal solution;

[0031] Step 3: Add Cu containing Cu to the Mn-doped ZnS nanocrystal solution obtained in Step 2 2+ The solution is reacted at 80-100° C. for 20-30 minutes, and air-cooled to room temperature to obtain a Cu-Mn double-doped ZnS quantum dot solution. Contains Cu 2+ The addition rate of the solution is generally controlled at 0.3-0.6mL / min to ensure that the Cu 2+ The ions are uniformly doped in the quantum dot crystal.

[0032] Among them: containing Zn 2+ The solution of Zn(C...

Embodiment 1

[0051] 1mmol of Zn(CH 3 COO) 2 , 2mmol of glutathione and a certain amount of 0.1mol / LMn(CH 3 COO) 2 The solution was added into a three-necked flask, and 100 mL of deionized water was added and stirred until the system was clear. Then use 1mol / L NaOH solution to adjust the pH value of the system to 10, raise the temperature to 60°C and continue stirring for 20min, then add 10mL freshly prepared 0.1mol / L NaOH dropwise. 2 S solution. After adding Na 2 After the S solution, the temperature of the system was raised to 100°C and kept at this temperature for 2 hours. At this time, a certain amount of 0.1mol / L Cu(CH 3 COO) 2 The solution was slowly added to the reaction system, the drip rate was controlled at 0.3-0.6mL / min through the infusion set, and the ratio range of the doping ion Cu / Mn was 1:0.1. After continuing the reaction for 30 min, the heating device was removed, and the reaction system was naturally cooled to room temperature to obtain a Cu-Mn double-doped ZnS qu...

Embodiment 2

[0053] 1mmol of Zn(CH 3 COO) 2 , 2mmol of cysteine and a certain amount of 0.1mol / LMn(CH 3 COO) 2 The solution was added into a three-necked flask, and 100 mL of deionized water was added and stirred until the system was clear. Then adjust the pH value of the system to 11 with 1mol / L NaOH solution, raise the temperature to 60°C and continue to stir for 20min, then add 10mL of freshly prepared 0.1mol / L NaOH dropwise. 2 S solution. After adding Na 2 After the S solution, the temperature of the system was raised to 80°C and kept at this temperature for 2h. At this time, a certain amount of 0.1mol / L Cu(CH 3 COO) 2 The solution was slowly added to the reaction system, the drip rate was controlled at 0.3-0.6mL / min through an infusion set, and the ratio of doping ions Cu / Mn was in the range of 1:1.0. After continuing to react for 20 min, the heating device was removed, and the reaction system was naturally cooled to room temperature to obtain a Cu-Mn double-doped ZnS quantum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com