A cottonseed protein production method capable of extracting various by-products

A production method and technology of cottonseed protein, applied in the field of cottonseed processing, can solve the problems of anti-nutritional substances and lipid substances having no effect, and achieve good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

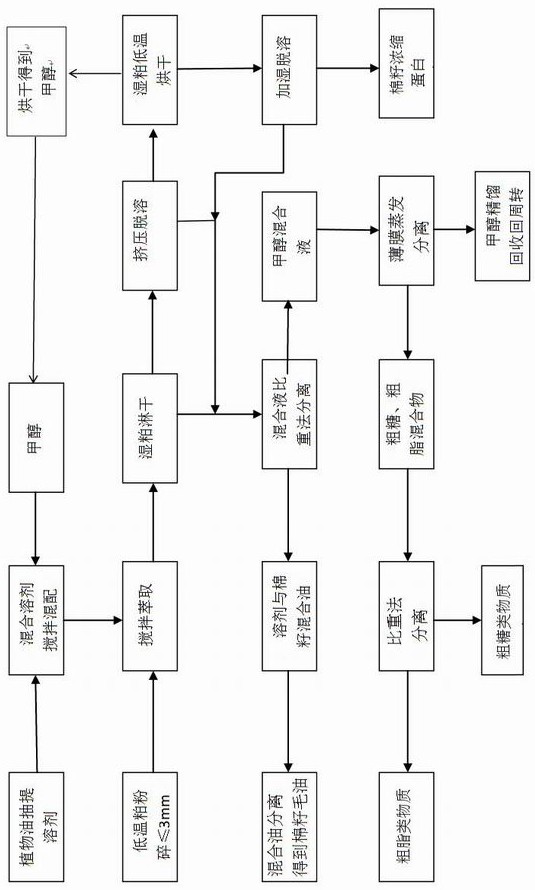

[0025] Embodiment one: a kind of cottonseed protein production method that can extract multiple by-products, this production method comprises the following steps:

[0026] 1) The meal powder is stirred and extracted under the action of a solvent. The solvent is a mixed solvent of methanol solution and vegetable oil extraction solvent. The meal powder is obtained by crushing the cottonseed low-temperature cake to a particle size ≤ 3mm. The cottonseed low-temperature cake refers to the cottonseed leaching meal , crush the raw material to a particle size ≤ 3mm. The concentration of the methanol solution of the mixed solvent is 75-90%. The mixing ratio of methanol and vegetable oil extraction solvent in the mixed solvent is 8:2. The mixed solvent of this ratio is used for the extraction of one-time leaching meal, and the extraction temperature is 30- At 55°C, the ratio of meal to solvent or meal to mixed solvent is ≤0.25.

[0027] 2) After extraction, the material is separated fr...

Embodiment 2

[0037] 1) The meal powder is stirred and extracted under the action of a solvent. The solvent is a mixed solvent of methanol solution and vegetable oil extraction solvent. The meal powder is obtained by crushing the cottonseed low-temperature cake to a particle size ≤ 3mm. For the processed cottonseed cake, the raw material is crushed to a particle size of ≤3mm. The concentration of the methanol solution of the mixed solvent is 80%, and the mixing ratio of methanol and vegetable oil extraction solvent in the mixed solvent is 6:4. The mixed solvent of this ratio is used for the extraction of low-temperature machine pressed cake, and the extraction temperature is 30-55°C , the ratio of meal to solvent or meal to mixed solvent is ≤0.25.

[0038] 2) After the extraction, the material is separated from the mixed solution, and the wet meal is obtained after the material is drenched;

[0039] 3) Desolventizing the wet meal, further extruding the wet meal for desolventization, the mo...

Embodiment 3

[0049] 1) The meal powder is stirred and extracted under the action of a solvent. The solvent is a mixed solvent of methanol solution and vegetable oil extraction solvent. The meal powder is obtained by crushing the cottonseed low-temperature cake to a particle size ≤ 3mm. After processing the cottonseed cake, these raw materials are crushed to a particle size ≤ 3mm. The concentration of the methanol solution that configures the mixed solvent is 90%, and the mixing ratio of methanol and vegetable oil extraction solvent in the mixed solvent is 9:1. The mixed solvent of this ratio is used for the extraction of the meal after cottonseed low-temperature puffing and oil extraction. The extraction temperature is 30-55°C, the ratio of meal powder to solvent or meal meal to mixed solvent is ≤0.25.

[0050] 2) After extraction, the material is separated from the mixed solution, and the material is drenched to obtain wet meal;

[0051] 3) Desolventizing the wet meal, further extruding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com