Single-phase multiferroic ceramic material and preparation method thereof

A technology of multiferroic ceramics and ceramic materials, applied in the field of multiferroic ceramics and its preparation, can solve the problems of weak magnetic properties of bismuth ferrite, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

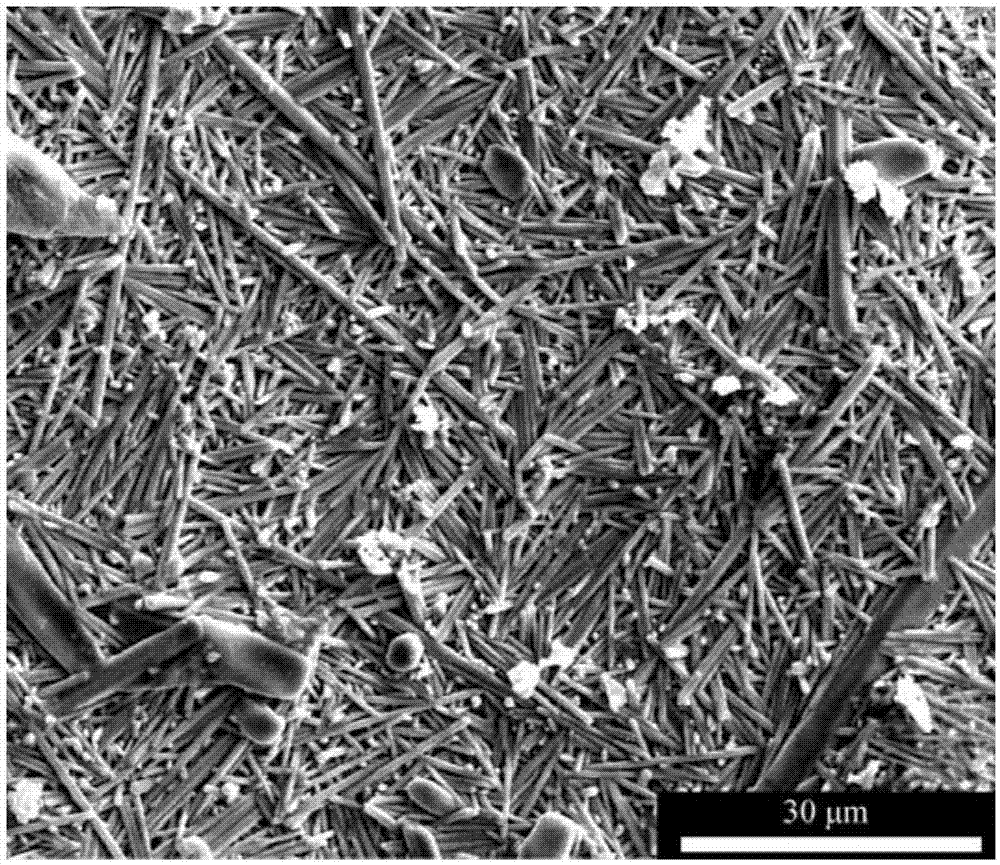

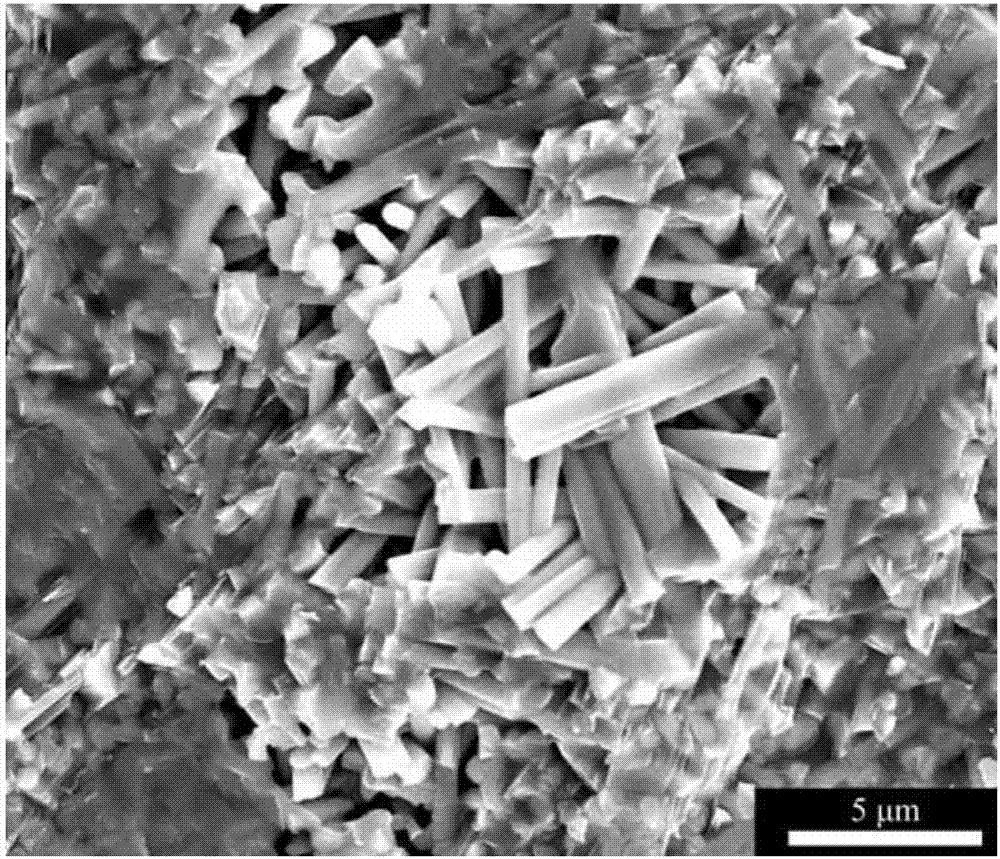

[0022] Specific embodiment one: the chemical expression of the single-phase multiferroic ceramic material of this embodiment is Ba 0.7 Ca 0.3 FeTaO 3 , and is a ceramic material composed of rod-shaped grains, abbreviated as BCFT.

[0023] The grain rods of the single-phase multiferroic ceramic material in this embodiment have a diameter of 0.5-1 μm and a length of 5-20 μm.

specific Embodiment approach 2

[0024] Specific embodiment two: the preparation method of the single-phase multiferroic ceramic material described in specific embodiment one, carries out according to the following steps:

[0025] 1. Barium carbonate (BaCO 3 ), calcium carbonate (CaCO 3 ), ferric oxide (Fe 2 o 3 ) and tantalum pentoxide (Ta 2 o 5 ) powder according to Ba 0.7 Ca 0.3 FeTaO 3 The stoichiometric ratio is weighed and mixed uniformly to obtain a mixed powder;

[0026] 2. Add alcohol to the mixed powder obtained in step 1, and ball mill in a ball mill at a speed of 200-400rpm for 12-48 hours to obtain a suspension A;

[0027] 3. Dry the suspension A obtained in step 2 to obtain powder A, and then put the powder A into a tube furnace and keep it at a temperature of 1100-1250°C for 3-6 hours to obtain a pre-calcined powder ;

[0028] 4. Add alcohol to the calcined powder obtained in step 3, and ball mill in a ball mill at a speed of 200-400 rpm for 12-48 hours to obtain a suspension B;

[0...

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 2 in that the drying temperature in Step 3 is 80° C. to 100° C.; others are the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com