Improved steel pipe clamping device with horizontal adjustment function

A clamping device and level adjustment technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of random adjustment of clamping, easy to loose and fall, and the firmness cannot be further guaranteed. Holds the steel pipe firmly, is convenient for cleaning and finishing, and has the effect of flexible processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

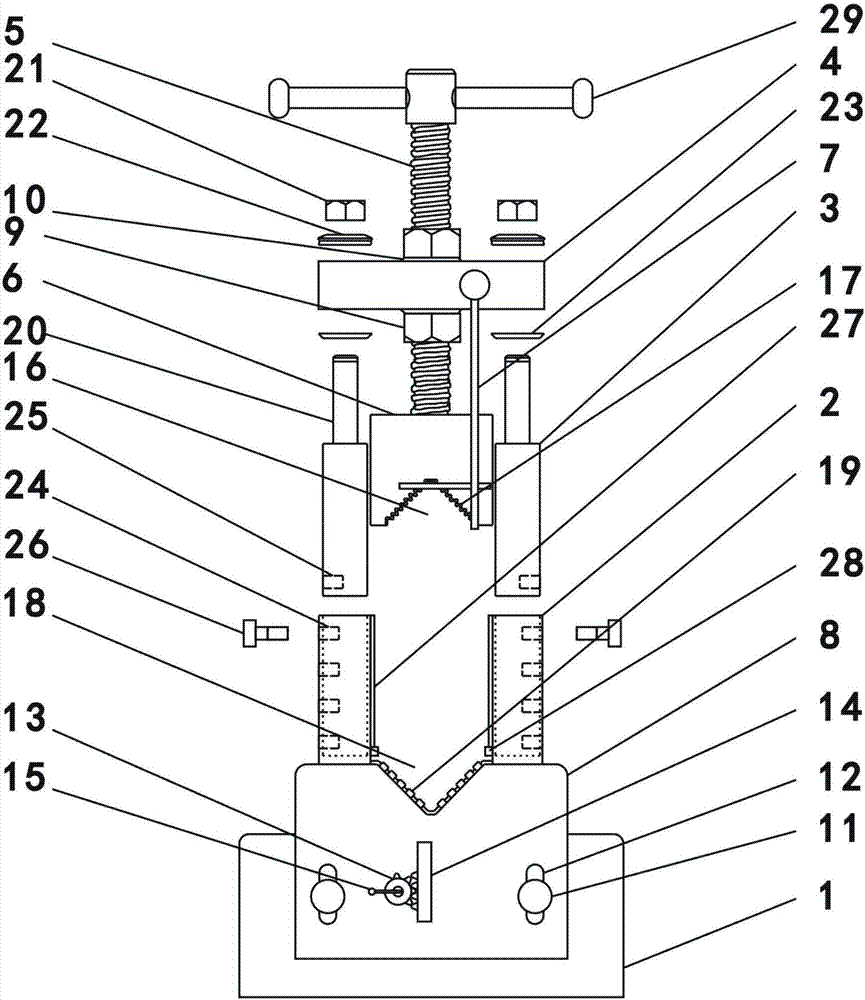

[0018] As an embodiment of the improved steel pipe clamping device with horizontal adjustment in the present invention, such as figure 1 As shown, it includes a base 1, a sleeve rod 2, a lifting rod 3, a cross bar 4, a screw rod 5, an upper clamping head 6, an elevation rod 7, a lower clamping head 8 and a fine-tuning assembly (not shown in the figure). The bottom of the base 1 is larger than the top of the base 1, the sleeve rods 2 are arranged on the left and right sides of the base 1, and the inside of the sleeve rods 2 is provided with vertical holes (not shown in the figure), so The elevating rod 3 is arranged inside the vertical opening (not shown in the figure), the cross bar 4 is arranged on the top of the elevating rod 3, and the middle part of the cross bar 4 is provided with a first through hole (fig. not shown), the screw rod 5 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com