Instant noodle processing method

A processing method and technology of instant noodles, which are applied in the directions of food forming, food science, application, etc., can solve the problems of unsuitable industrial production and cumbersome preparation process, and achieve the effect of simplifying the production process, reducing the preparation process steps, and reducing the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

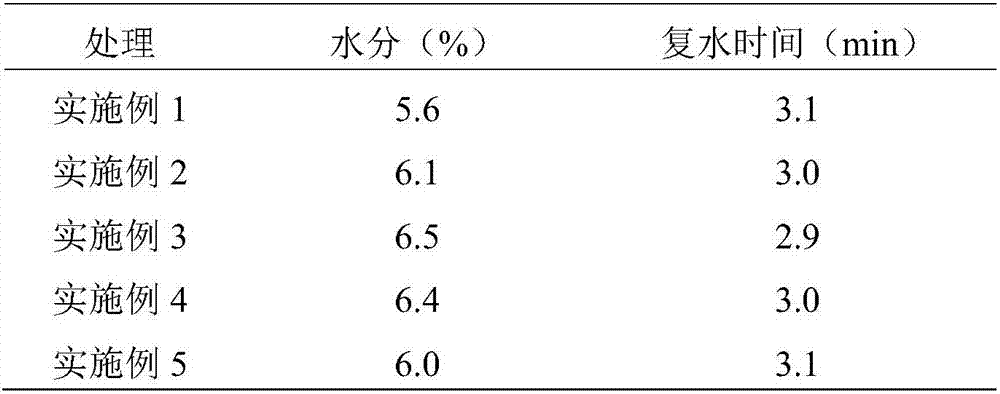

Examples

Embodiment 1

[0025] Embodiment 1: the total mass accounts for 2% of the finished product, and the mass percentage is 2:1:1:5 of β-cyclodextrin, soybean modified phospholipid, triglycerol monostearate and seasoning mixture, 1% salt, 0.3% sodium pyrophosphate, 0.4% guar gum, the balance is starch and water.

Embodiment 2

[0026] Embodiment 2: the total mass accounts for 2% of the finished product, and the mass percentage is 2:1:1:6 of β-cyclodextrin, soybean modified phospholipid, triglycerol monostearate and seasoning mixture, 1.5% salt, 0.4% sodium pyrophosphate, 0.5% guar gum, and the balance is starch and water.

Embodiment 3

[0027] Embodiment 3: the total mass accounts for 3% of the finished product, and the mass percentage is 2:1:1:5 of β-cyclodextrin, soybean modified phospholipid, tripolyglycerol monostearate and seasoning mixture, 2% salt, 0.5% sodium pyrophosphate, 0.5% guar gum, and the balance is starch and water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com