Low-sulfur marine fuel and preparation method thereof

A low-sulfur ship and fuel technology, applied to fuel, fuel additives, liquid carbon-containing fuel, etc., can solve problems such as price discounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

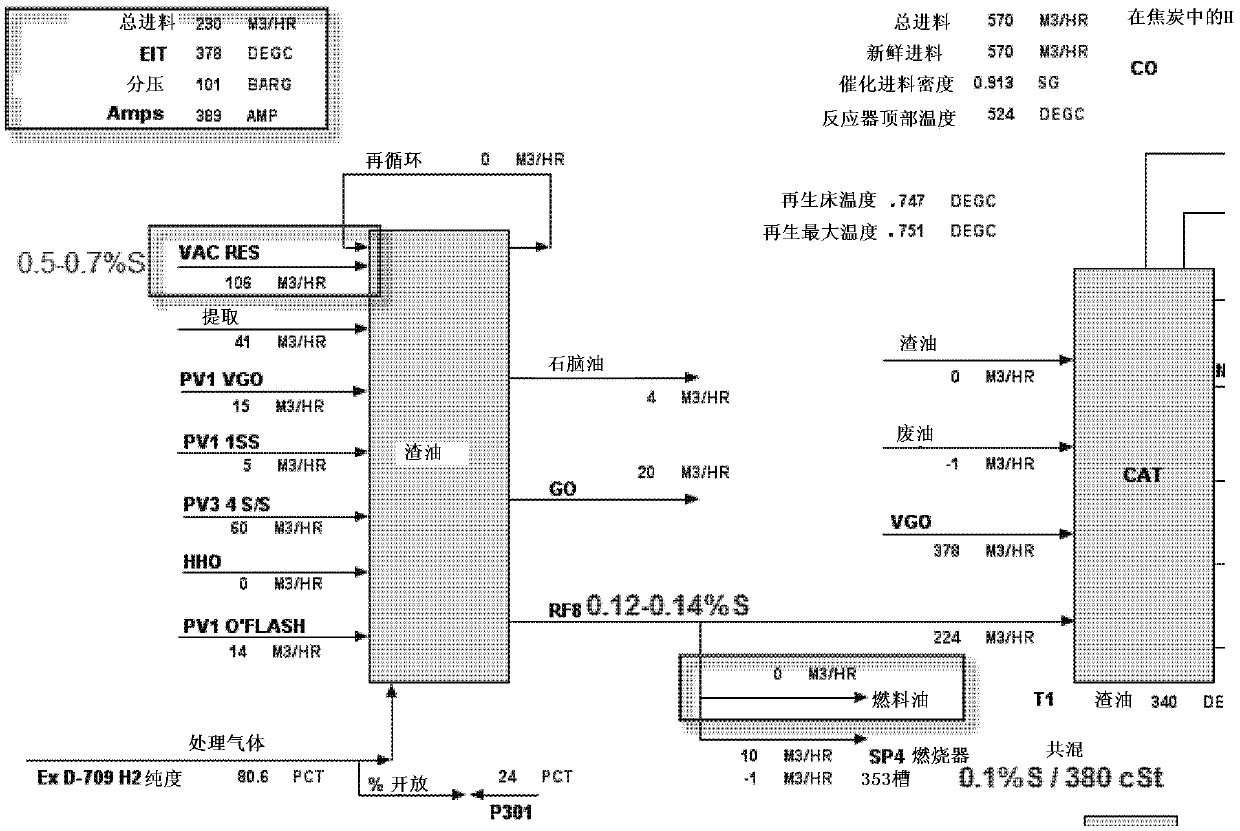

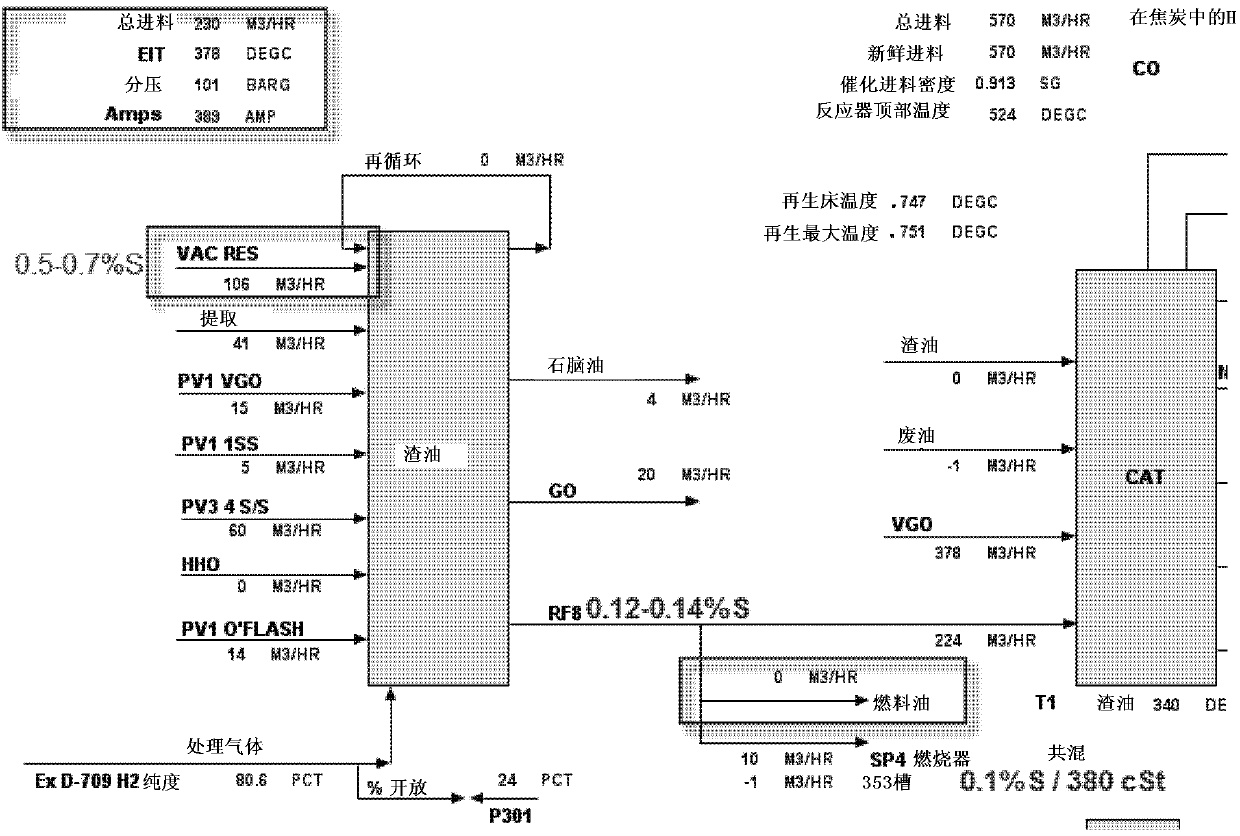

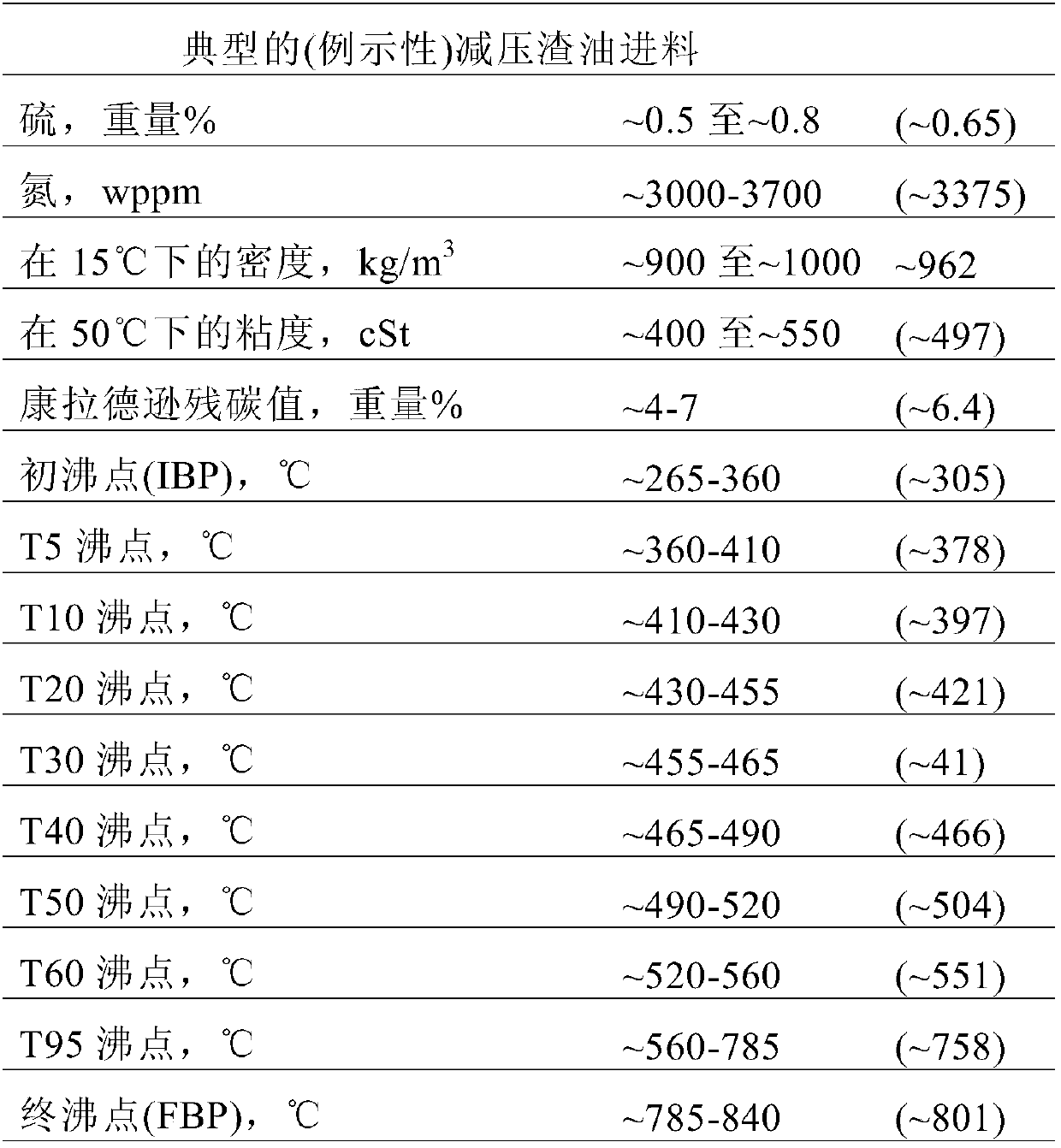

Method used

Image

Examples

Embodiment approach

[0087] Additionally or alternatively, the invention may include one or more of the following embodiments.

Embodiment approach 1

[0089] A method of making a low sulfur marine fuel composition, the method comprising: hydrotreating a vacuum residue feed stream with hydrogen in the presence of a hydrotreating catalyst to produce a vacuum residue without substantially cracking the vacuum residue reducing sulfur to no more than about 1500 parts per million (ppm); and combining said hydrotreated vacuum residue with no more than about 10 volume percent of a first diesel boiling range hydrocarbon stream and no more than about 40 % by volume of a second diesel boiling range hydrocarbon stream blended wherein said vacuum residue feed stream has from about 1000 ppm to about 10000 ppm sulfur and said first diesel boiling range hydrocarbon stream has no more than about 20 ppm sulfur, and The second diesel boiling range hydrocarbon stream has no more than about 10 ppm sulfur.

Embodiment approach 2

[0091] The process of embodiment 1, wherein the vacuum resid feed stream has from about 6000 ppm to about 10000 ppm sulfur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com