Cable crimping point and crimping fitting temperature rise experiment method

An experimental method and technology of crimping points, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

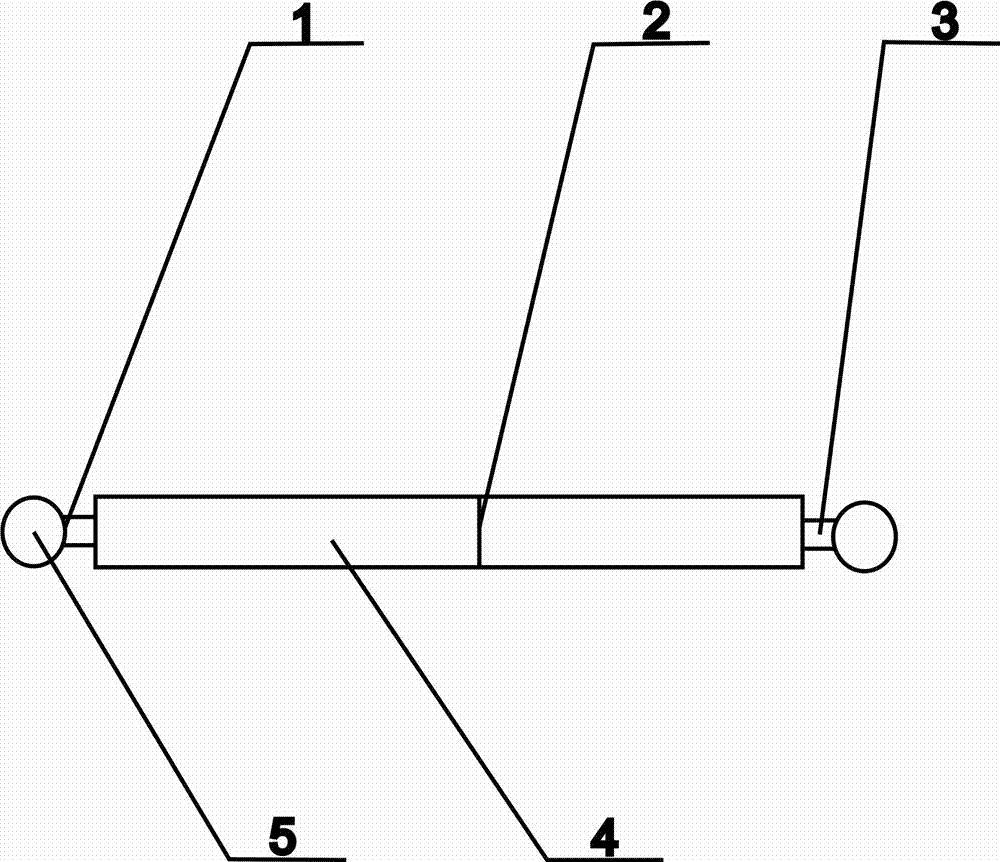

[0041] Embodiment 1, select sample length as 1m, rated section as 25 mm2

[0042] Step 1. Selection of the experimental environment: The temperature rise experiment of the cable crimping point and the crimping fitting 5 is carried out in an indoor environment that is not ventilated, airtight, and protected from light, and the indoor ambient temperature is 15°C;

[0043] Step 2. Selection of test equipment: the same test equipment is used for the lifting experiment of the cable crimping point and the crimping fitting 5, a large current generator, which provides a stable output current of 80A required for the experiment. Use a meter, a data acquisition card, A set of thermocouples constitutes a reliable measurement system, and a torque wrench to ensure reliable terminal connection, the torque setting value is 10 Nm;

[0044] Step 3. Preparation of experimental crimped cable samples: crimp the crimped cable 4 with the crimping fitting 5 of the same specification. Both ends of the...

Embodiment 2

[0053] Embodiment 2, select sample length as 1m, rated section as 95 mm2

[0054] Step 1. Selection of the experimental environment: the temperature rise experiment of the cable crimping point and the crimping fitting 5 is carried out in a non-ventilated, airtight, and light-proof indoor environment, and the indoor ambient temperature is controlled at 25°C;

[0055] Step 2. Selection of test equipment: the same test equipment is used for the lifting experiment of the cable crimping point and the crimping fitting 5, a large current generator, which provides a stable output current of 260A required for the experiment; a multimeter, a data acquisition card, a thermoelectric Even a set to form a reliable measurement system, and a torque wrench to ensure reliable terminal connection, the torque setting value is 20Nm;

[0056] Step 3. Preparation of experimental crimped cable samples: crimp the crimped cable 4 with the crimping fitting 5 of the same specification. Both ends of the c...

Embodiment 3

[0065] Embodiment 3, select sample length as 1m, rated section as 240 mm2

[0066] Step 1. Selection of the experimental environment: The temperature rise experiment of the cable crimping point and the crimping fitting 5 is carried out in a non-ventilated, airtight, and light-proof indoor environment, and the indoor ambient temperature is controlled at 30°C;

[0067] Step 2. Selection of test equipment: The same experimental equipment is used for the test of the cable crimping point and the crimping fitting 5, a large current generator, which provides a stable output current of 590A for the experiment, a multimeter, a data acquisition card, a thermoelectric Even a set to form a reliable measurement system, and a torque wrench to ensure reliable terminal connection, the torque setting value is 35Nm;

[0068] Step 3. Preparation of experimental crimped cable samples: crimp the crimped cable 4 with the crimping fitting 5 of the same specification. Both ends of the cable must be cri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com