A Pneumatic Delay Reversing Valve

A reversing valve and valve core technology, which is used in fluid pressure actuating devices, servo motor components, mechanical equipment, etc. Due to the complex structure of the valve, the effects of light weight, increased delay range and small size are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

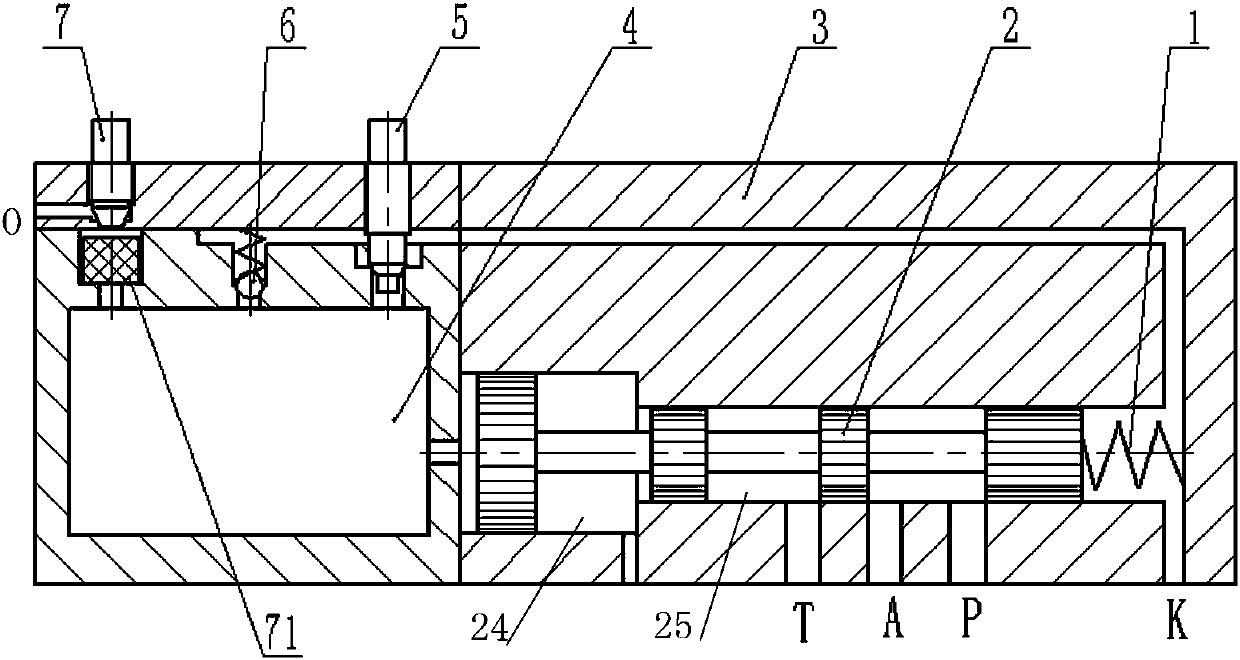

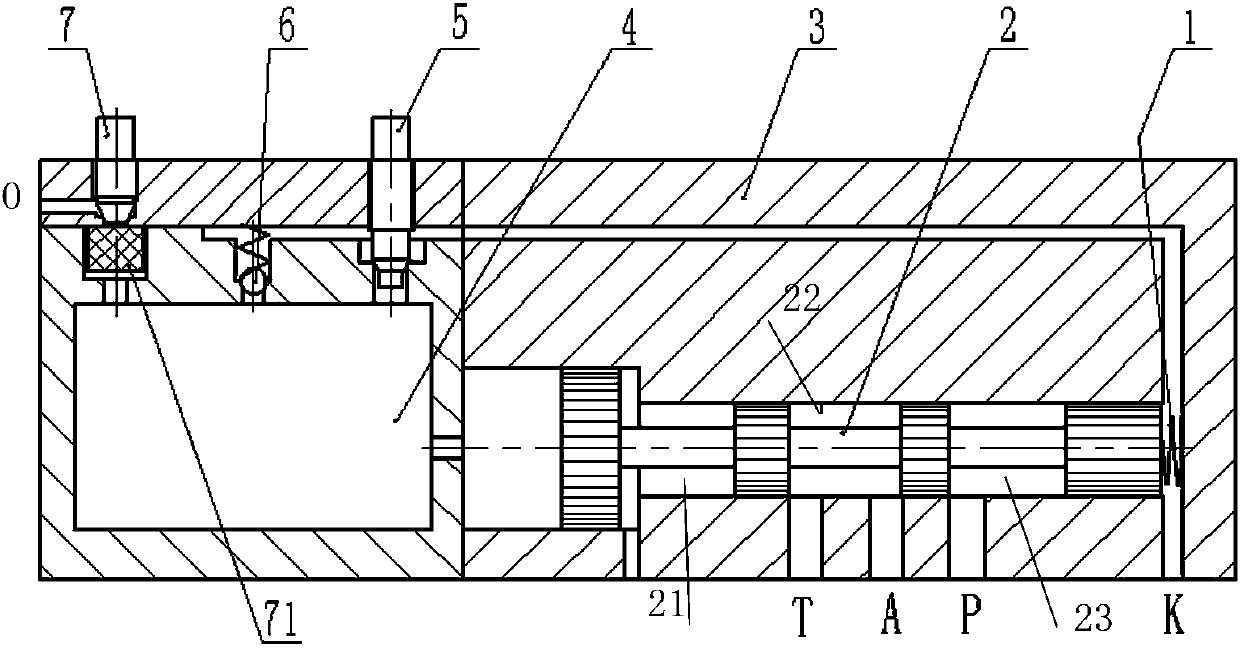

[0023] like Figure 1-2 The pneumatic time-delay reversing valve shown is composed of spring 1, spool 2, valve body 3, air chamber 4, throttle valve 5, check valve 6, miniature throttle valve 7 and composed of elastic columns 71; the left end of the valve body 3 is provided with an air chamber 4, and the right end is provided with a stepped valve core cavity, the valve core 2 and spring 1 are coaxially placed in the valve core cavity, and the spring 1 is located At the right end of the spool, the spool 2 is slidingly fitted with the spool chamber, and a through hole for communicating with the air chamber 4 and the spool chamber is provided between the air chamber 4 and the spool chamber; in the valve body 1. Throttle valve 5, one-way valve 6 and micro-throttle valve 7 are arranged on the upper end, and the air chamber 4 communicates with the vent hole at the bottom of said throttle valve 5, one-way valve 6 and micro-throttle valve 7 respectively , the flow rate of the micro-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com