Tunnel secondary lining rebar positioning, laying and ejecting device

A technology for ejecting devices and tunnels, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc. It can solve the problems of inconvenient positioning of circumferential steel bars, low positioning efficiency, and deformation of circumferential steel bars, so as to facilitate accurate laying and jacking Out, reduce the probability of deformation, reduce the effect of the probability of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

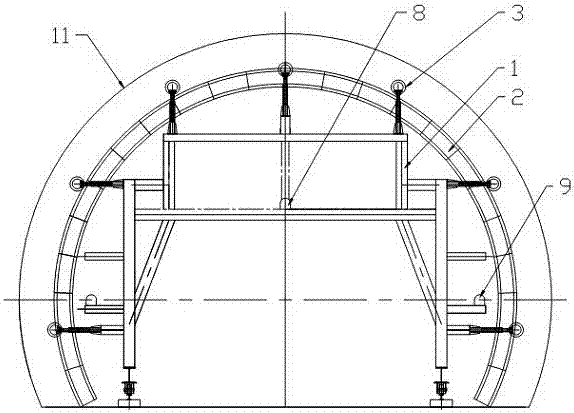

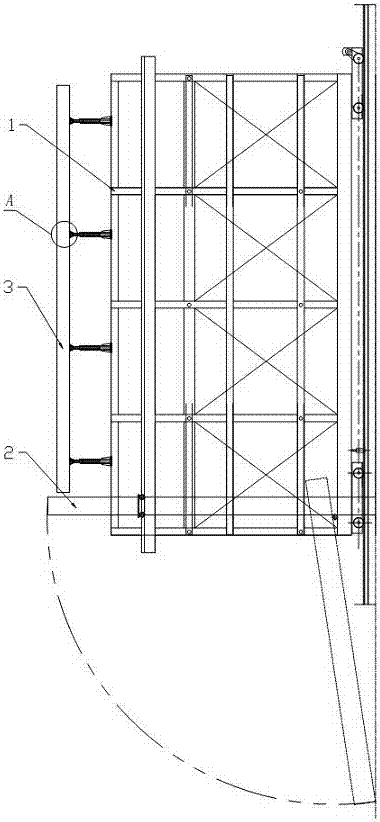

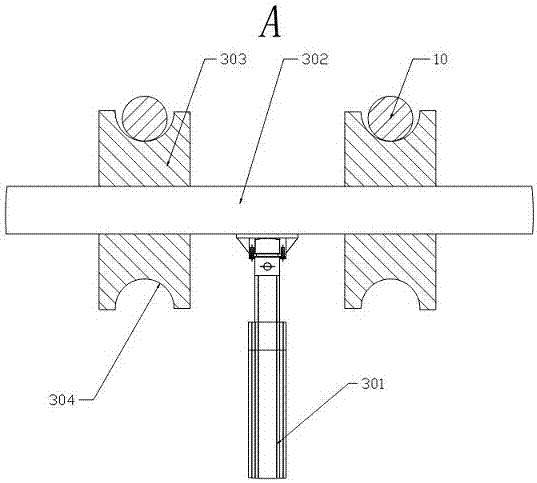

[0023] The reference signs in the drawings of the description include: stand 1, container 2, ejector 3, screw screw ejector 301, ejector rod 302, positioning wheel 303, groove 304, commutator 4, steering Device 5, connecting rod 6, motor 7, vertical line throwing instrument 8, horizontal line throwing instrument 9, hoop steel bar 10, tunnel 11.

[0024] The positioning, laying and ejection devices of the second lining of the tunnel in the embodiment are basically as attached figure 1 And attached figure 2 Shown: including the platform 1 and the positioning mechanism arranged on the platform 1, the laying mechanism and the ejection mechanism, the positioning mechanism includes the vertical positioning cylinder vertically arranged at the bottom of the platform 1 and the vertical positioning cylinder horizontally arranged on both sides of the vertical positioning cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com