Gap cap entrapment composite well completion method

A composite, gas-cap technology, applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as low productivity and increase seepage area, and achieve increased seepage area, straight streamline, The effect of improving the productivity of a single well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

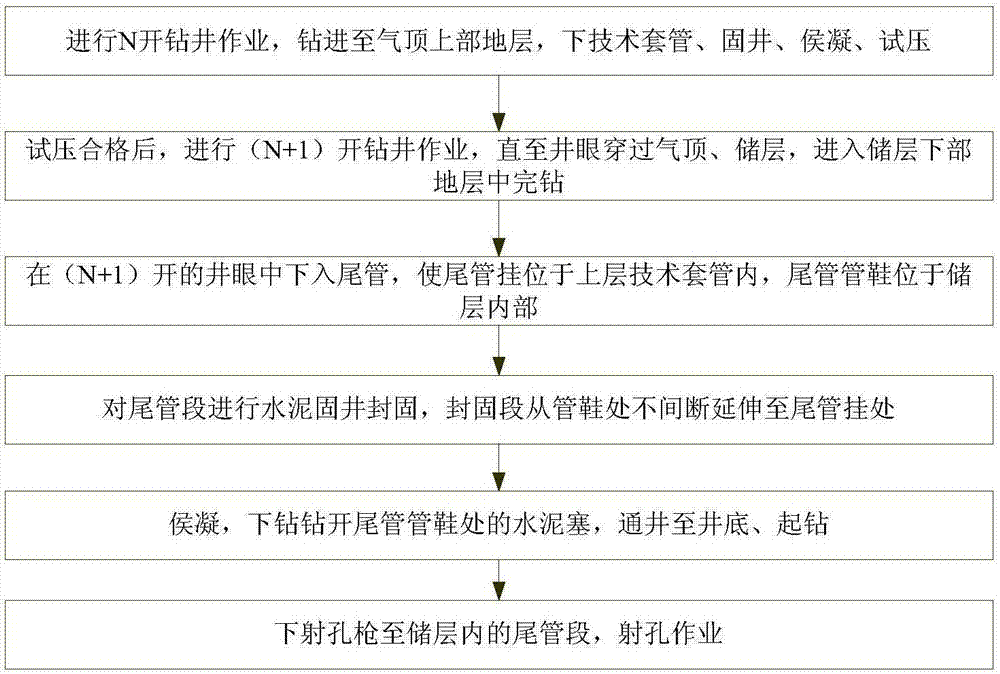

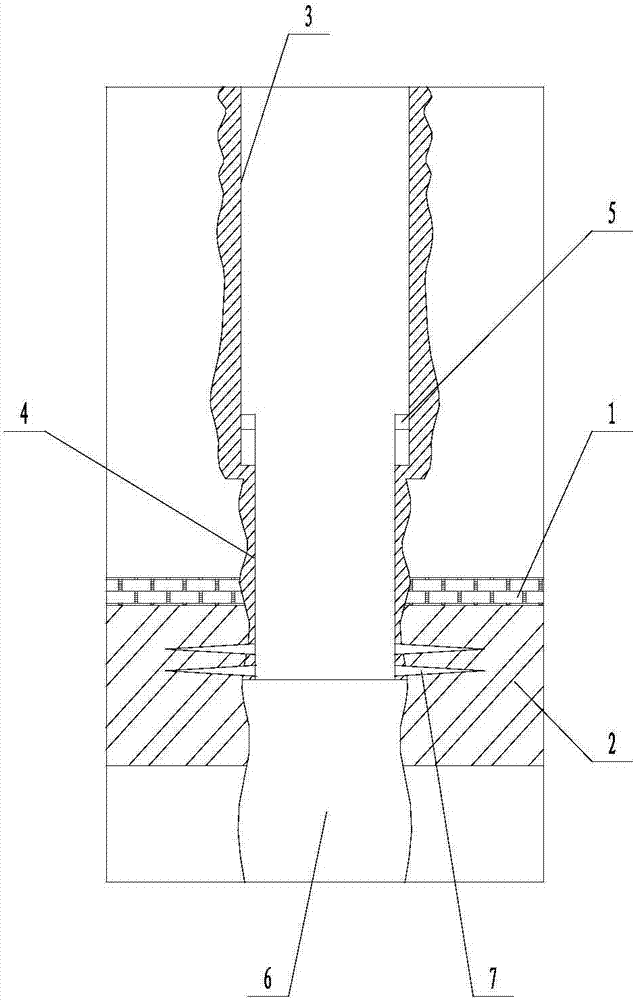

[0022] Such as figure 1 and figure 2 The compound well completion method of the gas cap trap shown includes the following steps: (a) perform second drilling operation, drill into the stratum above the gas cap, install technical casing, cement, hold, and pressure test; ( b) After passing the pressure test, carry out three-split drilling operations until the wellbore passes through the gas cap and the reservoir, and enters the formation below the reservoir to complete the drilling; The hanger is located in the upper technical casing, and the liner shoe is located inside the reservoir; (d) the liner section is cemented and sealed, and the sealing section extends from the shoe to the liner hanger without interruption; (e) Hou Ning , run down the drill to open the cement plug at the liner shoe, pass the well to the bottom of the well, and pull out the drill; (f) run down the perforating gun to the liner section in the reservoir, and perform perforating operations. The distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com