Biodegradable polymer composite material and preparation method thereof

A technology of biodegradation and composite materials, which is applied in the field of biodegradable polymer composite materials and its preparation, can solve the problems of poor mechanical properties and achieve the effects of increased glass transition temperature, high saturation concentration, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

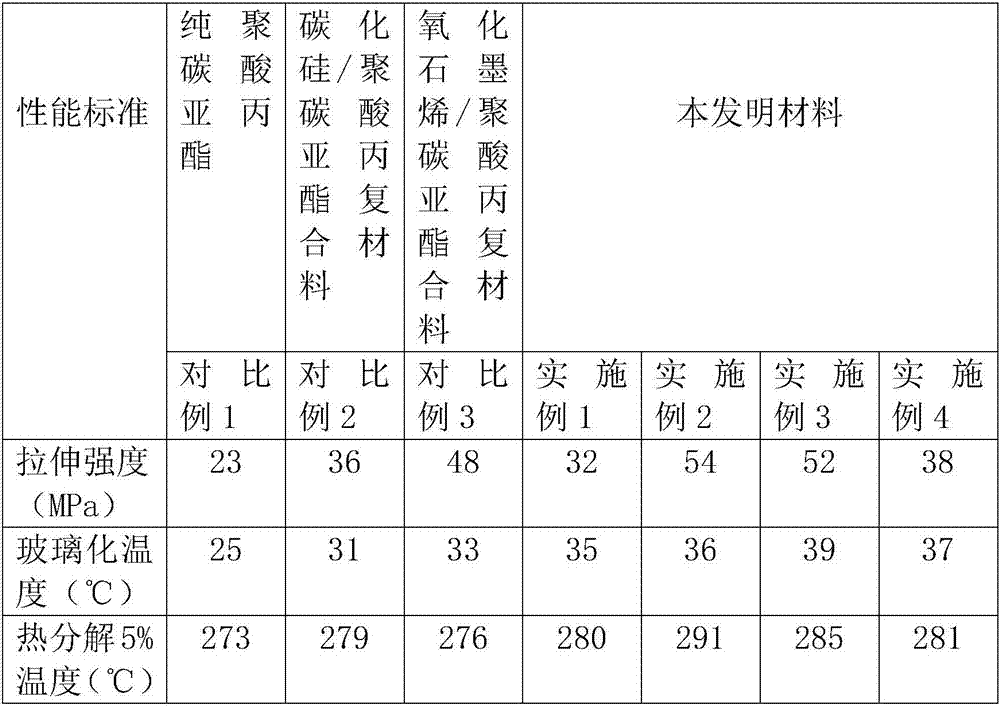

Examples

Embodiment 1

[0040] 800mg of silicon carbide nanorods and 16g of hydrogen peroxide solution were refluxed at 100°C for 6h, cooled to room temperature, filtered, washed with deionized water repeatedly, and dried to obtain silicon carbide nanorods with surface hydroxylation.

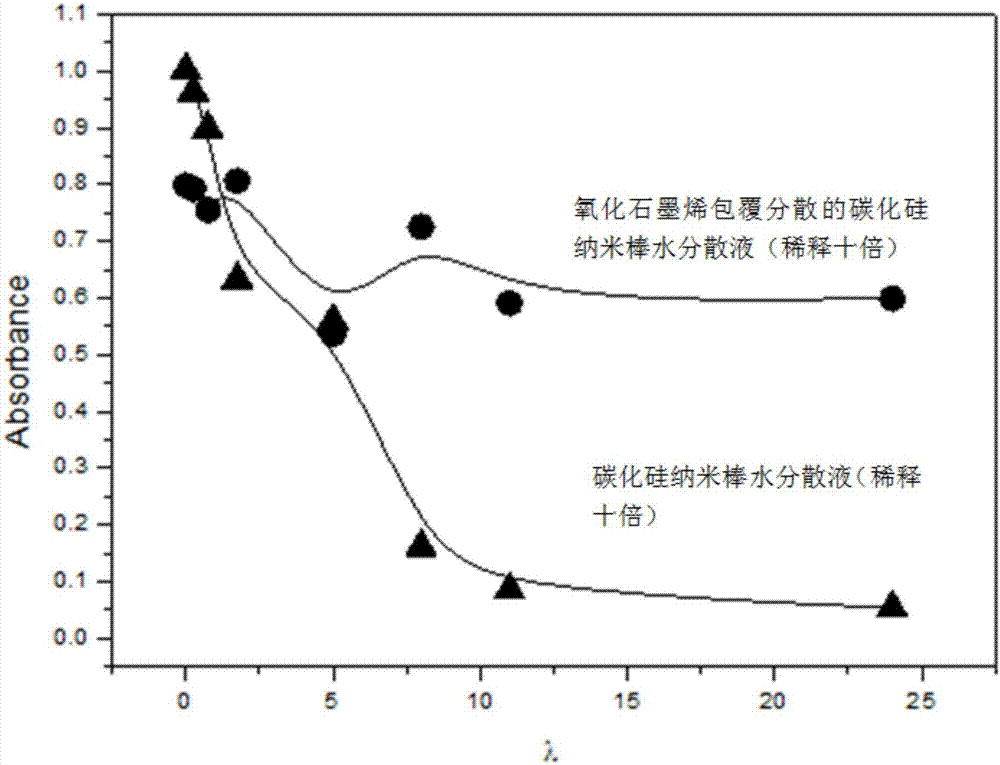

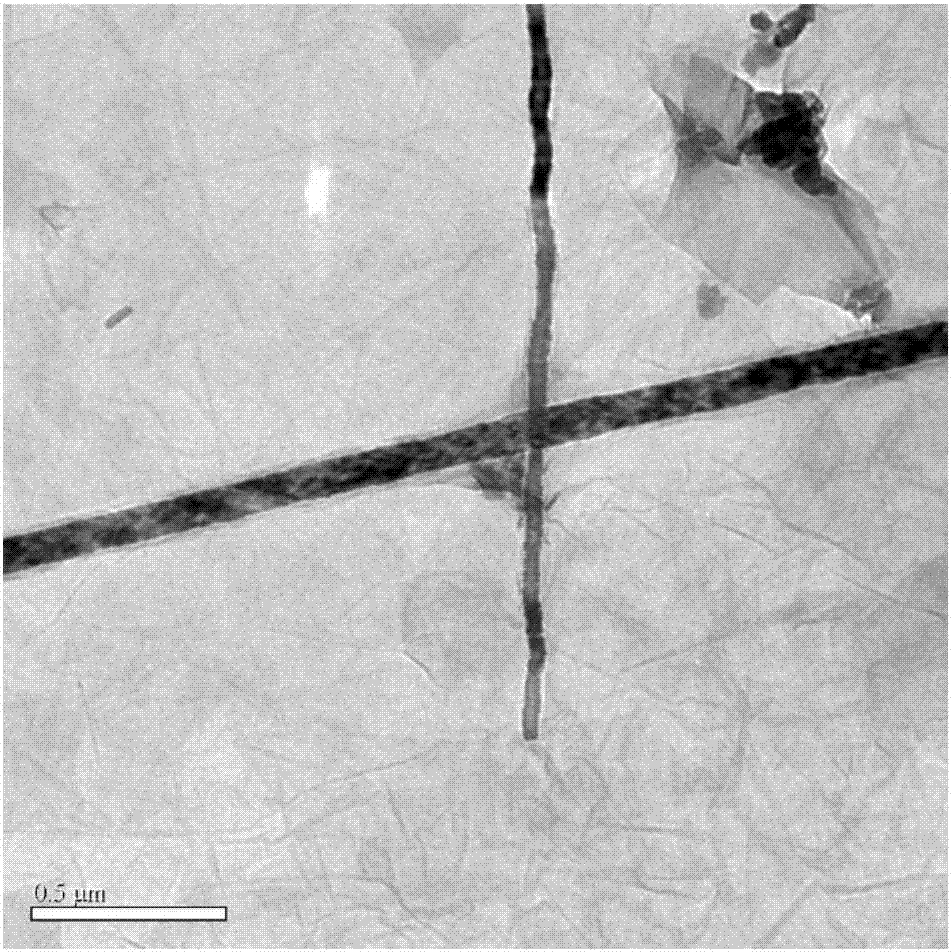

[0041] Add 500 mg of the above-mentioned surface hydroxylated silicon carbide nanorods to 500 ml of graphene oxide aqueous dispersion with a concentration of 10 mg / ml, and take it out after ultrasonic dispersion for 2 hours. Dilute the upper layer saturated dispersion liquid ten times in time intervals, and use the UV spectrophotometer to obtain the sedimentation curve (such as figure 1 Shown). After the solution is allowed to stand for 24 hours, take a small amount of the aqueous solution of the upper layer of saturated graphene oxide coated and dispersed silicon carbide nanorods, and observe the coating structure (such as figure 2 Shown). The remaining saturated upper layer liquid is freeze-dried to obtain graphene ox...

Embodiment 2

[0044] 800mg of silicon carbide nanorods and 32g of hydrogen peroxide solution were refluxed at 60°C for 5h, cooled to room temperature, filtered, washed repeatedly with deionized water, and dried to obtain silicon carbide nanorods with surface hydroxylation.

[0045] Add 500 mg of the above-mentioned surface hydroxylated silicon carbide nanorods to 500 ml of graphene oxide aqueous dispersion with a concentration of 3 mg / ml, and take it out after ultrasonic dispersion for 2 hours. The obtained mixed solution was centrifuged at 3000 r / min for 20 min. The obtained upper-layer saturated graphene oxide coated and dispersed silicon carbide nanorod aqueous solution is freeze-dried to obtain graphene oxide coated silicon carbide nanorod powder.

[0046] 700 mg of graphene oxide coated silicon carbide nanorod powder and 10 g of polypropylene carbonate were dissolved in 250 ml of N,N-dimethylformamide, and mechanically stirred at 40°C for 3 hours. The solution is re-precipitated with a lar...

Embodiment 3

[0048] 1g of silicon carbide nanorods and 25g of hydrogen peroxide solution were refluxed at 95°C for 4h, cooled to room temperature, filtered, repeatedly washed with deionized water, and dried to obtain silicon carbide nanorods with surface hydroxylation.

[0049] Add 600mg of the above-mentioned surface hydroxylated silicon carbide nanorods to 600ml of graphene oxide aqueous dispersion with a concentration of 5mg / ml, ultrasonically disperse for 3h, then take it out, stand for 24h, take the upper layer of saturated graphene oxide to disperse the silicon carbide nanorod aqueous solution Freeze drying obtains graphene oxide coated silicon carbide powder.

[0050] Dissolve 240 mg of graphene oxide coated silicon carbide nanorod powder and 4.8 g of polypropylene carbonate in 100 ml of ethanol, and mechanically stir at 40° C. for 3 hours. The solution is re-precipitated with a large amount of deionized water, washed, dried, and hot-pressed to obtain a graphene oxide-coated silicon carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Maximum tensile strength | aaaaa | aaaaa |

| Maximum tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com