Writing brush cleaning device

A technology for cleaning devices and writing brushes, which is applied to devices for removing nibs, printing, writing utensils, etc., and can solve the problems of damaged brushes, slow cleaning speed, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

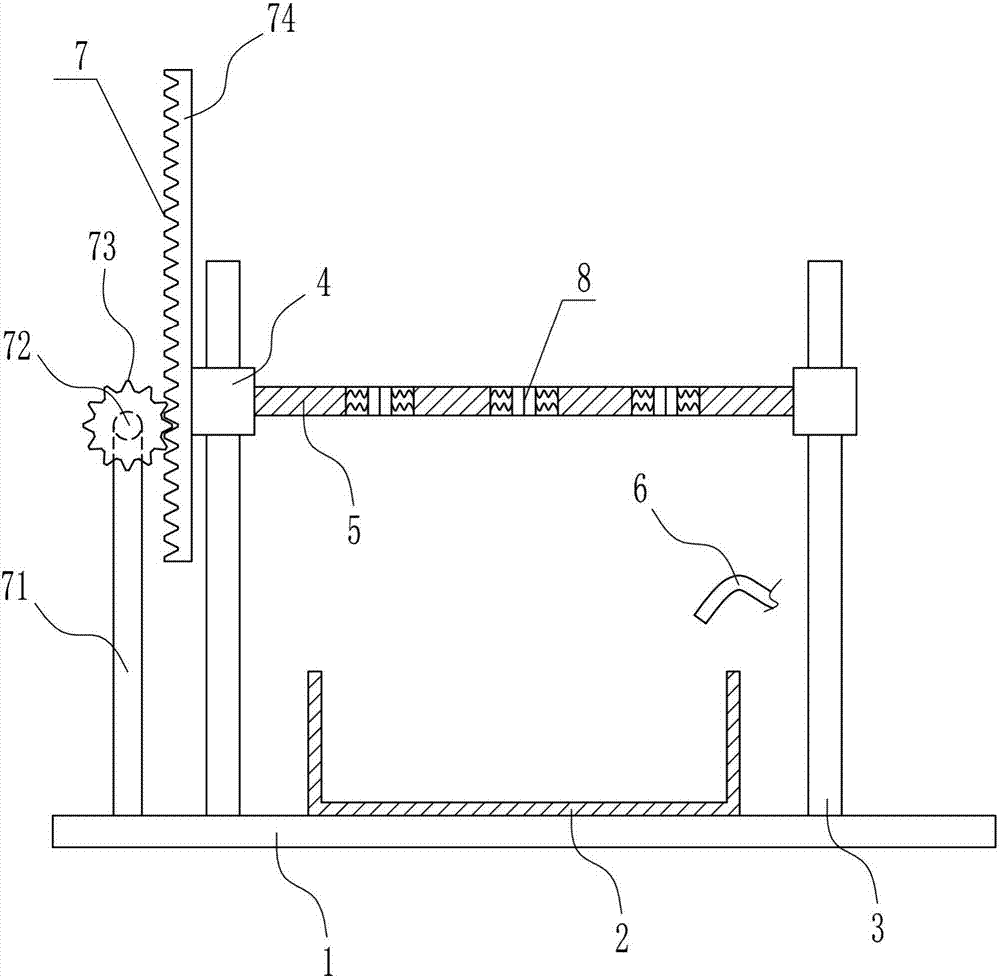

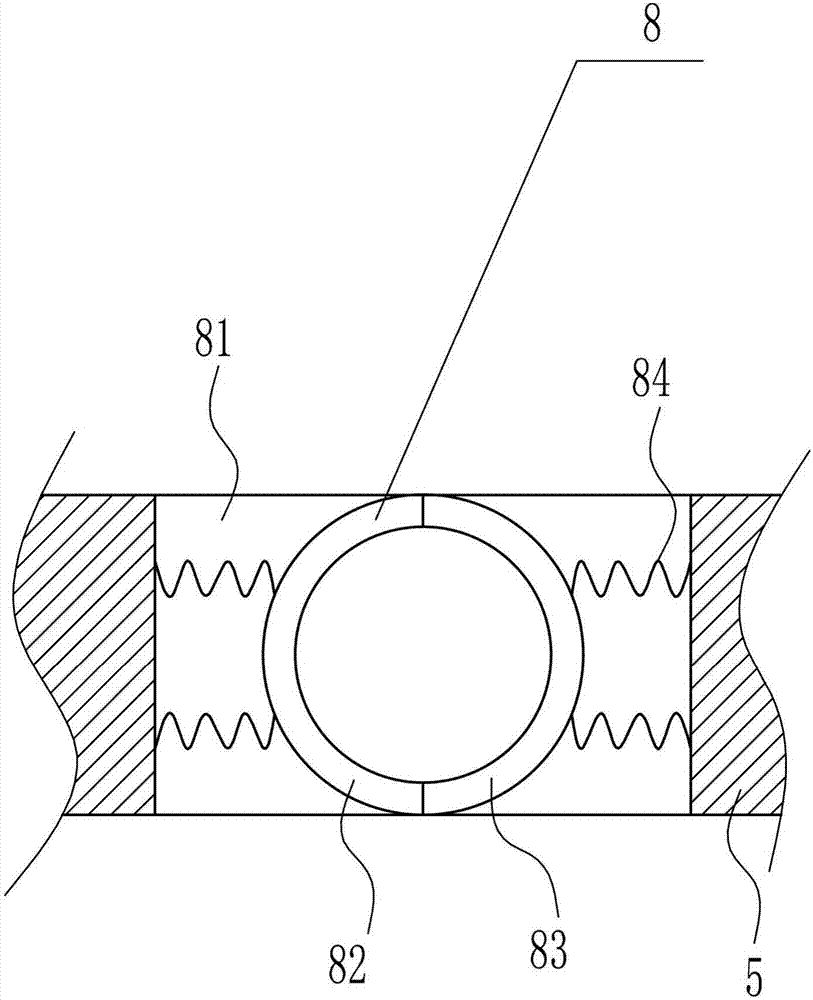

[0029] A cleaning device for brushes, such as Figure 1-5 As shown, it includes a bottom plate 1, a frame body 2, a sliding rod 3, a sliding sleeve 4, a horizontal plate 5, a water inlet pipe 6, a lifting device 7 and a fixing device 8, and the frame body 2 is installed in the middle of the top of the bottom plate 1 by bolts. , the left and right sides of the top of the bottom plate 1 are connected by bolts to install the sliding rod 3, the sliding sleeve 4 is installed on the sliding rod 3, the sliding sleeve 4 and the sliding rod 3 are slidingly matched, and the middle part of the right side of the left sliding sleeve 4 is connected to the right A horizontal plate 5 is installed between the middle part of the left side of the side sliding sleeve 4 through a bolt connection, and a fixing device 8 is provided on the horizontal plate 5, and a lifting device 7 is provided on the left side of the top of the bottom plate 1, and the lifting device 7 is located on the left sliding ro...

Embodiment 2

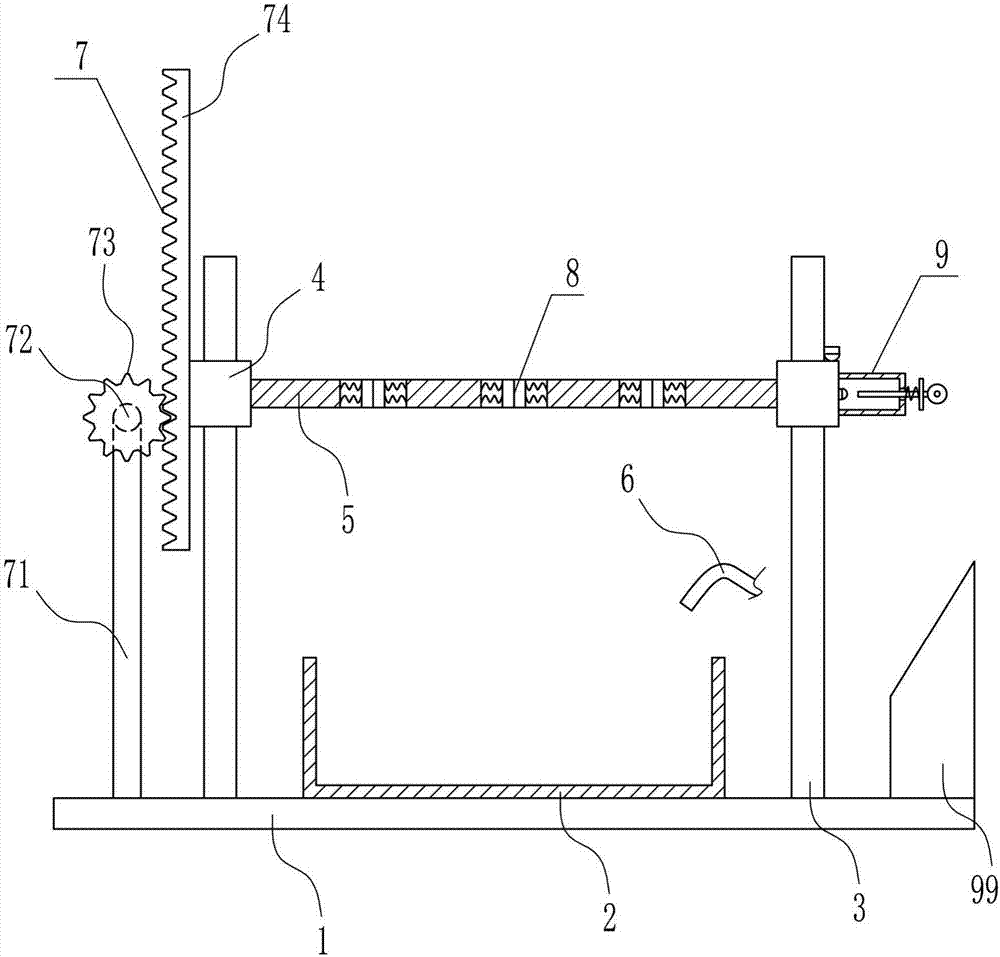

[0031] A cleaning device for brushes, such as Figure 1-5As shown, it includes a bottom plate 1, a frame body 2, a sliding rod 3, a sliding sleeve 4, a horizontal plate 5, a water inlet pipe 6, a lifting device 7 and a fixing device 8, and the frame body 2 is installed in the middle of the top of the bottom plate 1 by bolts. , the left and right sides of the top of the bottom plate 1 are connected by bolts to install the sliding rod 3, the sliding sleeve 4 is installed on the sliding rod 3, the sliding sleeve 4 and the sliding rod 3 are slidingly matched, and the middle part of the right side of the left sliding sleeve 4 is connected to the right A horizontal plate 5 is installed between the middle part of the left side of the side sliding sleeve 4 through a bolt connection, and a fixing device 8 is provided on the horizontal plate 5, and a lifting device 7 is provided on the left side of the top of the bottom plate 1, and the lifting device 7 is located on the left sliding rod...

Embodiment 3

[0034] A cleaning device for brushes, such as Figure 1-5 As shown, it includes a bottom plate 1, a frame body 2, a sliding rod 3, a sliding sleeve 4, a horizontal plate 5, a water inlet pipe 6, a lifting device 7 and a fixing device 8, and the frame body 2 is installed in the middle of the top of the bottom plate 1 by bolts. , the left and right sides of the top of the bottom plate 1 are connected by bolts to install the sliding rod 3, the sliding sleeve 4 is installed on the sliding rod 3, the sliding sleeve 4 and the sliding rod 3 are slidingly matched, and the middle part of the right side of the left sliding sleeve 4 is connected to the right A horizontal plate 5 is installed between the middle part of the left side of the side sliding sleeve 4 through a bolt connection, and a fixing device 8 is provided on the horizontal plate 5, and a lifting device 7 is provided on the left side of the top of the bottom plate 1, and the lifting device 7 is located on the left sliding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com