Electromagnetic stirring analyzing and constructing method based on electrical magnesite smelting furnace

A technology of electromagnetic stirring and electric melting magnesium furnace, which is applied in the direction of electric digital data processing, special data processing applications, instruments, etc., and can solve the problems of limited arc heat range and uneven heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

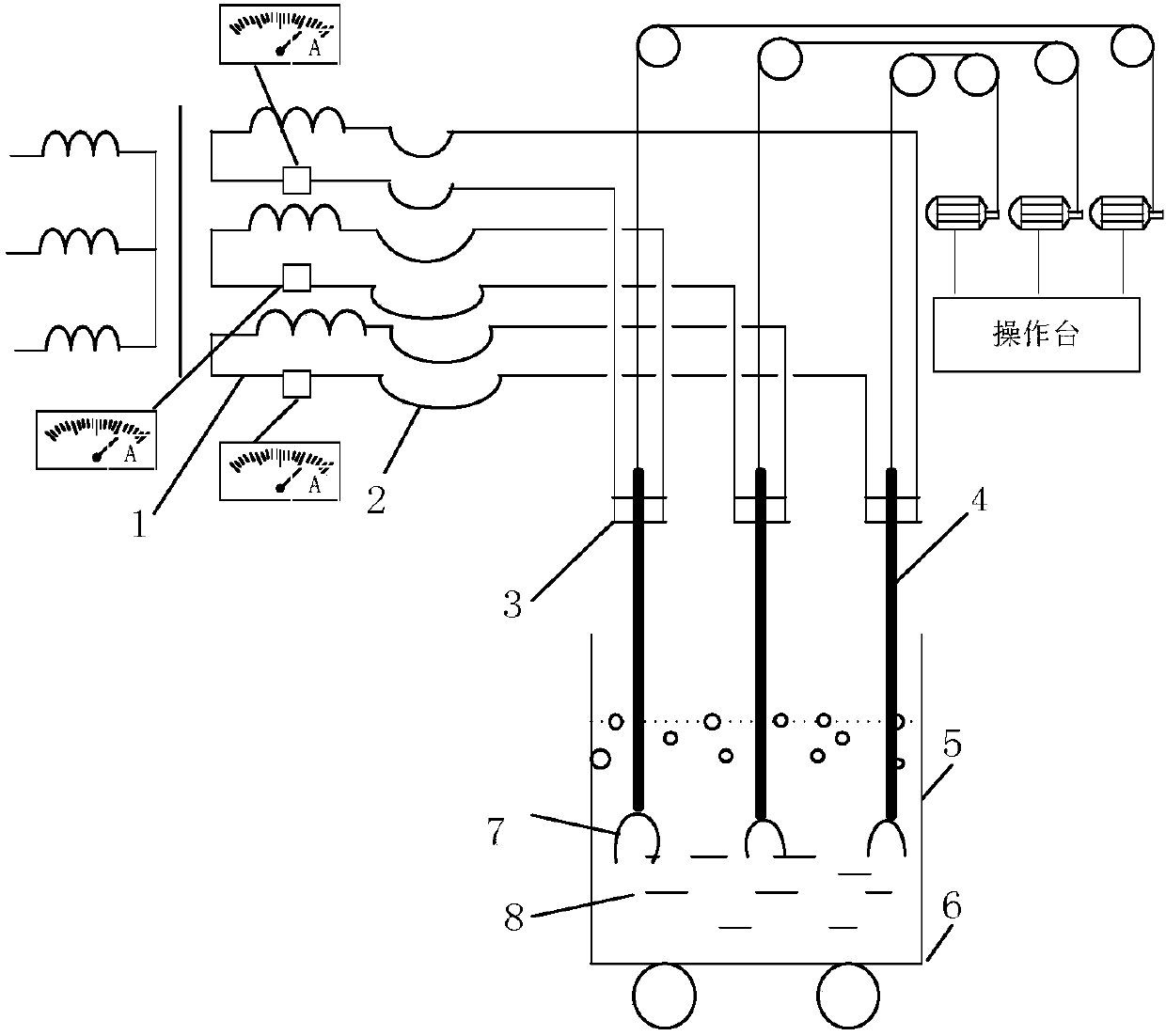

[0089] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0090] The method of the invention is analyzed and constructed according to the theory of electromagnetic stirring, which is composed of three basic theories: Biot-Savart law, Faraday's law of electromagnetic induction and Lorentz formula. In the rotating electromagnetic stirring, an alternating magnetic field is generated after the alternating current is passed through. When the alternating magnetic field passes through the conductive material solution, an induced electromotive force is induced, thereby generating an induced current. The interaction between the electromagnetic field and the induced current finally generates an electromagnetic force. The electromagnetic force can be decomposed into radial electromagnetic force and tangential electromagnetic force, and electromagnetic stirring is to stir the conductive solution under the action of low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com