A friction block capable of intelligently detecting wear and real-time temperature and its detection method

A technology of real-time temperature and friction block, applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems of cumbersome detection process, ineffective detection of friction block, low accuracy, etc., to reduce detection The process and the number of times, the effect of avoiding the weakening of the braking effect and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

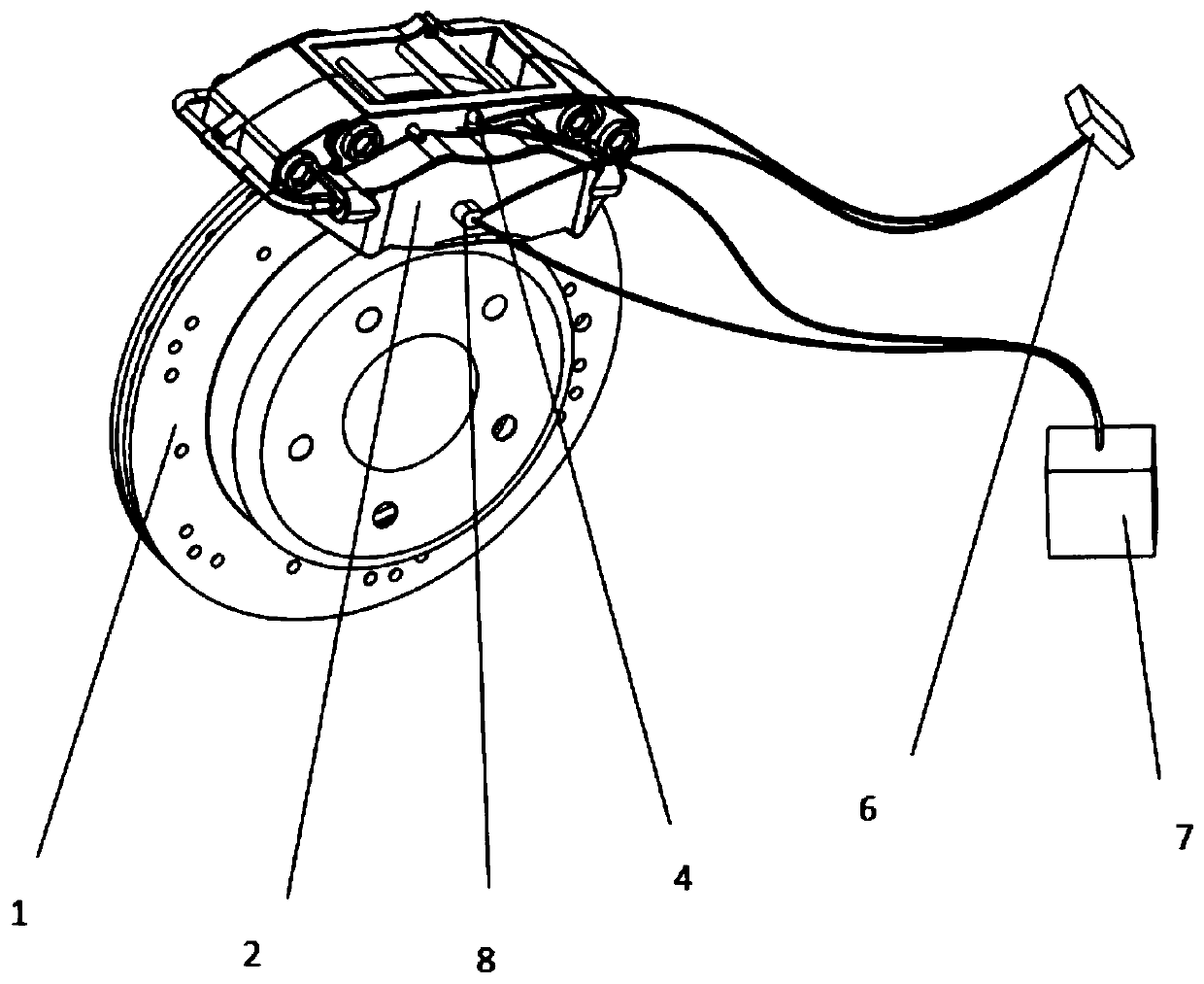

[0034] Embodiment 1: as Figure 1-5 As shown, a friction block that can intelligently detect wear and real-time temperature includes a brake friction disc 1, a caliper 2, a friction block 3, a display 6, a battery 7, a digital temperature sensor 8, a control module 9, and a friction block thickness detection module 10. LED buzzer 11, the battery 7 is connected with the friction block thickness detection module 10 and the digital temperature sensor 8 respectively, and then connected with the control module 9, and the control module 9 is connected with the display 6 and the LED buzzer 11 respectively;

[0035] The friction block thickness detection module 10 includes a plurality of precision resistors 4, each precision resistor 4 is connected in series with a fixed-value resistor respectively and then connected to the control module 9, and the precision resistors 4 are connected in parallel and then connected to the battery 7;

[0036] The friction blocks 3 are respectively fixe...

Embodiment 2

[0045] Embodiment 2: Because the voltage change is an analog quantity, and what the single-chip microcomputer needs is a discrete digital quantity, so it is necessary to convert the voltage change on the precision resistor 4 through an analog-to-digital conversion circuit to convert the analog quantity into a digital quantity. Therefore, the precision resistors 4 are respectively connected to IN0-IN7 of the A / D conversion circuit to perform analog and digital conversion. The A / D conversion circuit converts the output to the single-chip microcomputer through the bus, and then sends it to the single-chip microcomputer to analyze and calculate the relationship between the voltage on the resistor and the thickness of the friction plate. Since there is no clock in the A / D conversion circuit, the address latch enable signal (pin ALE) provided by the microcontroller is obtained after the D flip-flop (U6:A) is divided by 2, and provided to the A / D conversion circuit clock signal, D tr...

Embodiment 3

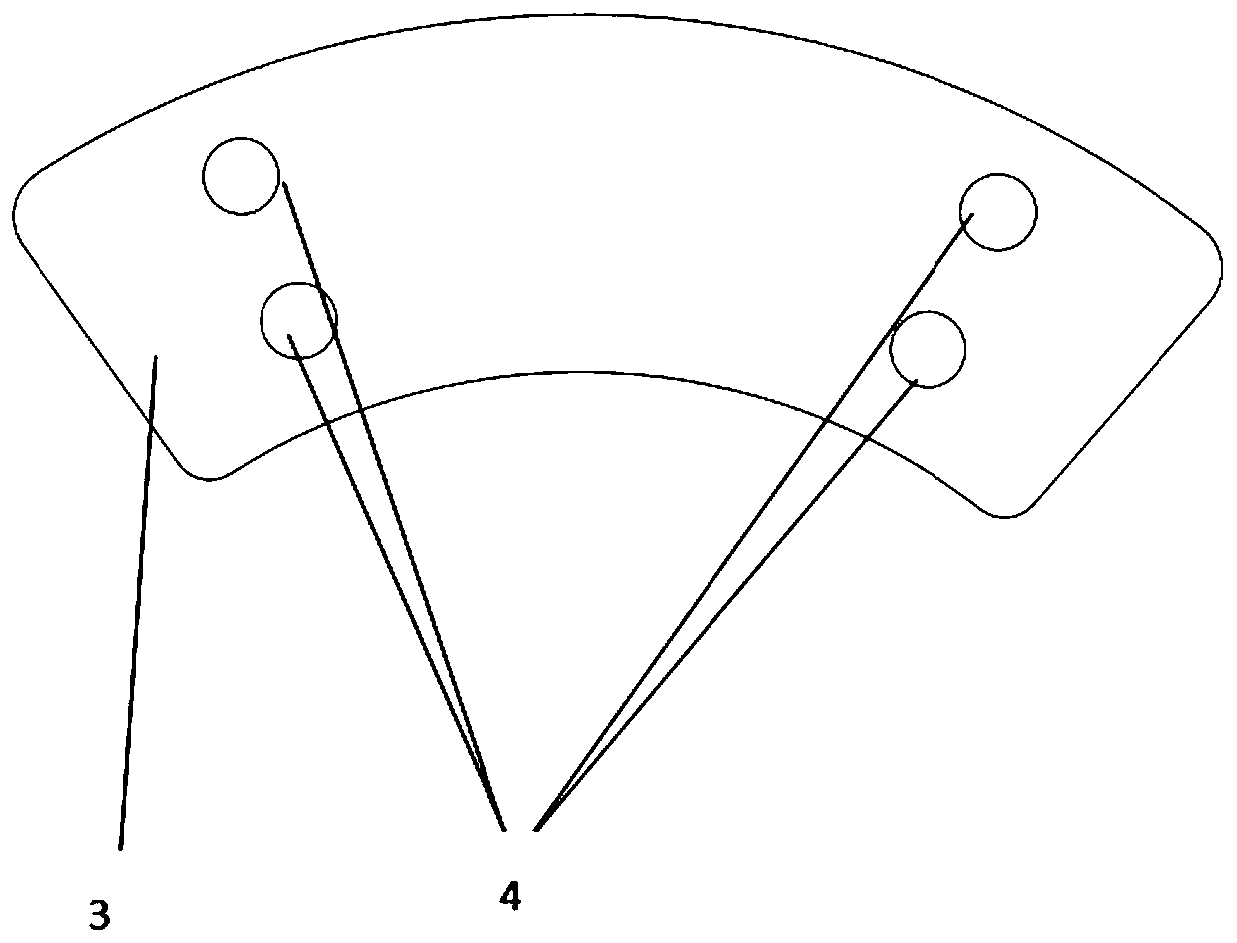

[0050] Embodiment 3: Because the length of each precision resistor 4 can only represent the thickness near the modified point, and cannot represent the thickness of the entire friction block 3, because the improper installation of the friction block 3 will cause different wear conditions in different places, each There are four precision resistors 3 on the block friction block 3, and the four precision resistors 3 form a rectangular surface, and the specific distribution is as follows: image 3 As shown, this will make the final output result most representative of the thickness of the entire friction block 3, and the wear conditions at different places can be seen according to the absolute value of the difference between different precision resistors 4. Eight 1K fixed-value resistors are respectively connected in series with eight 1K precision resistors to divide the voltage of 5V. When they are not worn out, they each occupy 2.5V, and then connect one end of the eight precisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com