Internal oblique teeth built-up crankshaft type RV speed reducer of industrial robot

A technology of industrial robots and combined crankshafts, which is applied to mechanical equipment, gear transmissions, gear lubrication/cooling, etc., can solve problems such as high cost of profiling devices, low gear shaping efficiency, and impracticality, so as to ensure machining accuracy, Good casting performance and low friction factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

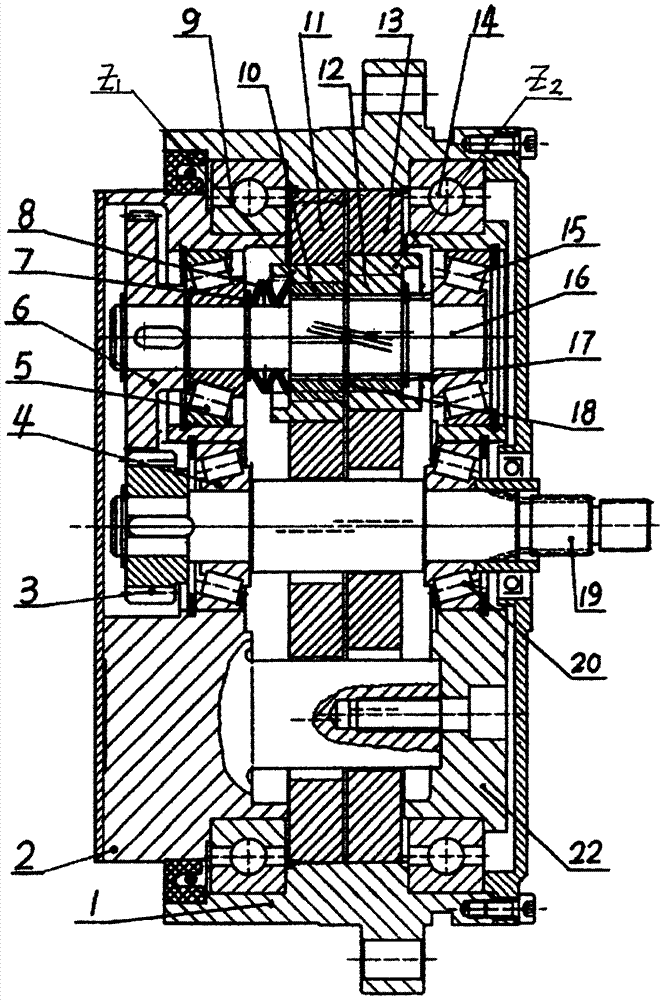

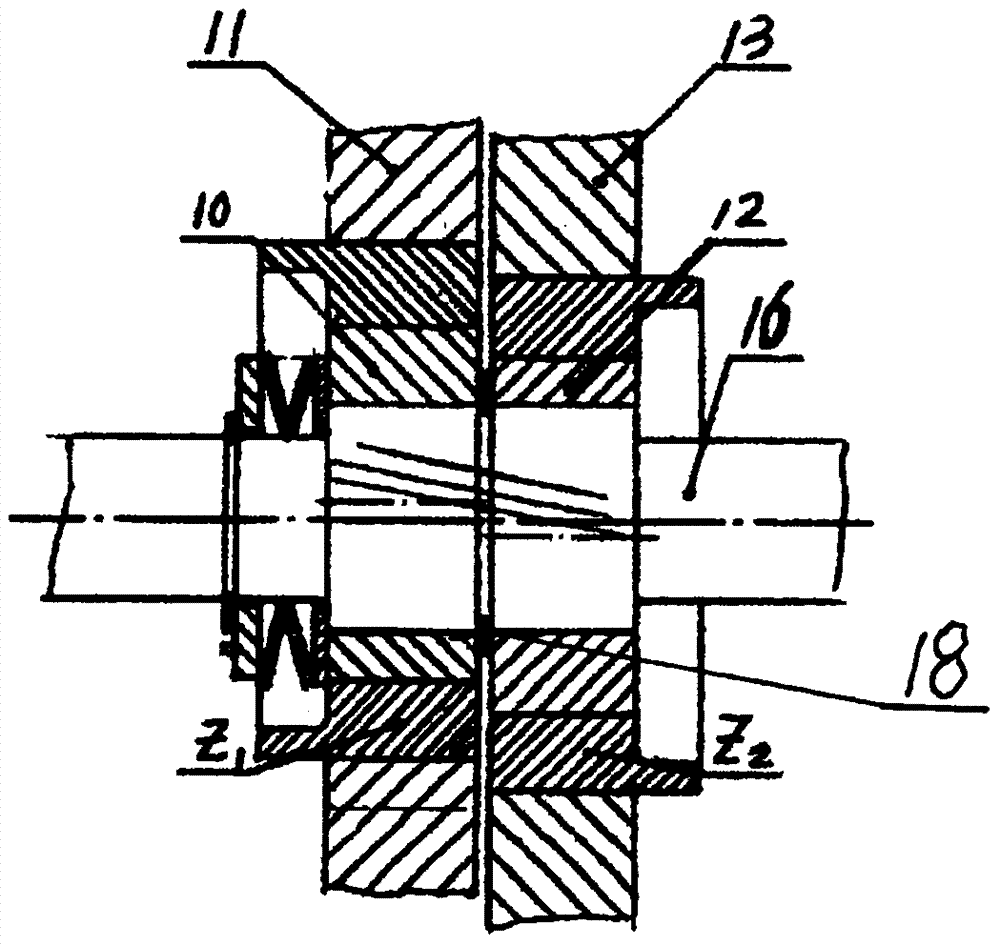

[0035] Such as Figure 1-2 As shown, an RV reducer of an industrial robot internal helical gear combined crankshaft type includes a cycloidal component and a planetary component. The cycloidal component includes a hypocycloidal ring gear 1, left and right rigid discs 2, 22 and a first , the second cycloidal wheel 11,13, the uniform flange on the left rigid plate 2 passes through the two cycloidal wheels and the right rigid plate 22 to be connected to a rigid body, and the left and right rigid plates 2,22 use the first 1. The second bearings 9, 14 are respectively supported in the inner holes on both sides of the hypocycloid ring gear 1, and the planetary components include the input shaft 19, the sun gear 3, the planetary gear 6 and the planetary shaft 16 arranged on the input shaft 19, The input shaft 19 is respectively supported on the left and right rigid discs 2 and 22 center holes with the third and fourth bearings 4 and 20, and the fifth and sixth bearings 5 and 15 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com