A hydraulic oil intelligent purification detection and control device

A technology for purifying detection and control devices, used in fluid pressure actuation devices, fluid pressure actuation system testing, fluid pressure actuation system components, etc. There are many problems such as uncertainty, to achieve the effect of reducing work intensity, good application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

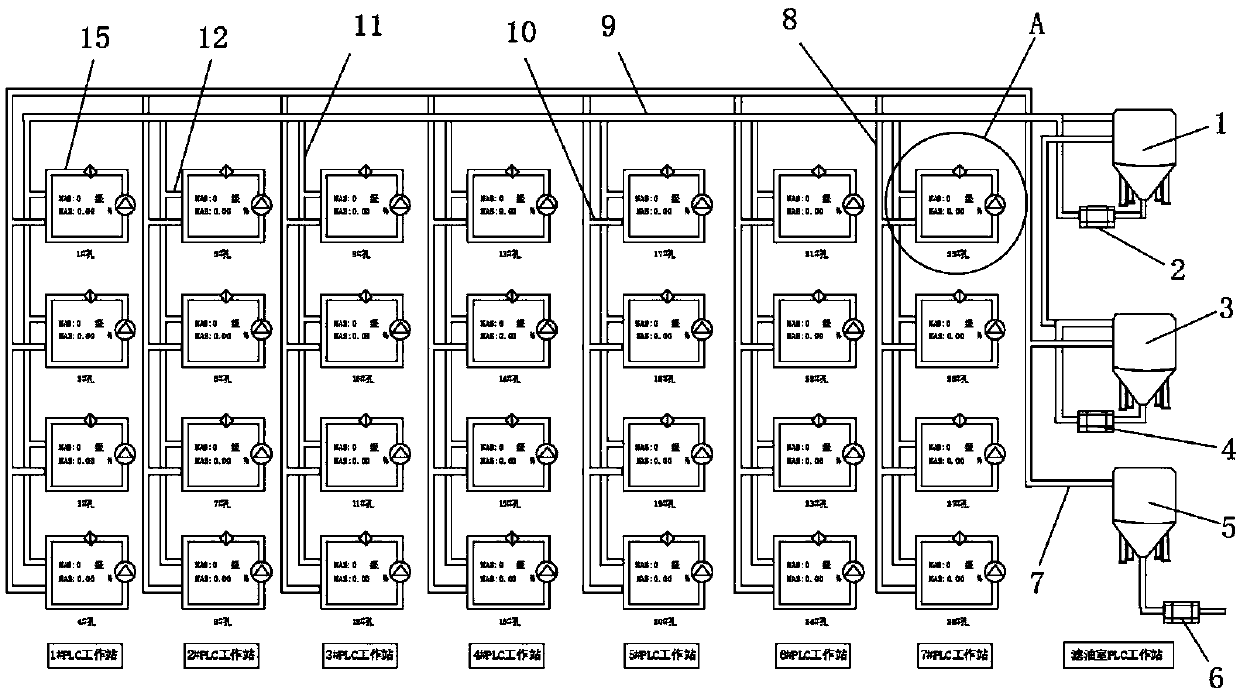

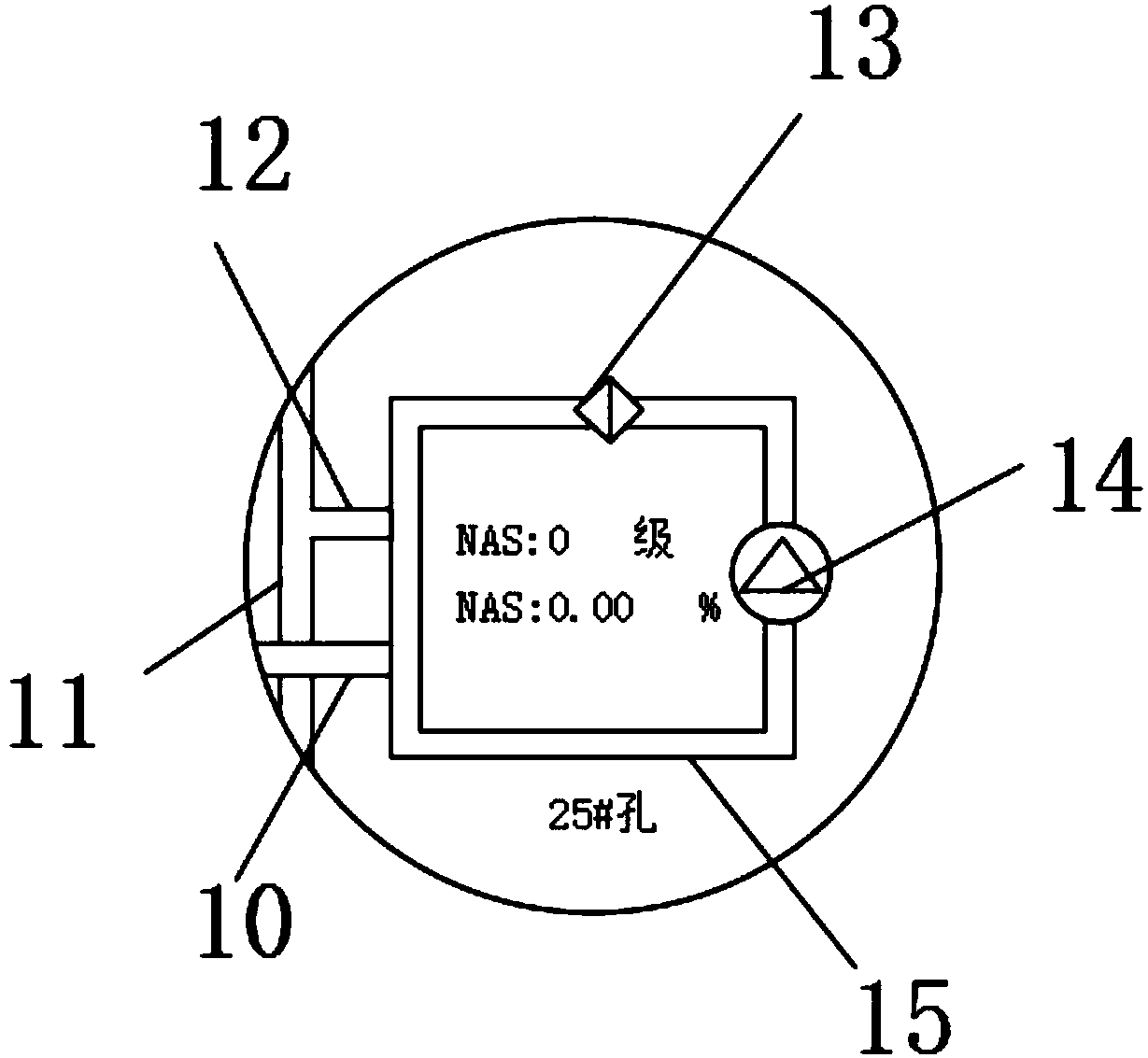

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0016] refer to Figure 1-2 , a hydraulic oil intelligent purification detection control device, including a plurality of online particle size detection sensors 14, clean oil tank 1, operating oil tank 3 and dirty oil tank 5, both sides of the online particle size detection sensor 14 are connected with circulation Pipeline 15, the two ends of circulating pipeline 15 are respectively connected with first pipeline 10 and second pipeline 12, and first pipeline 10 is connected with third pipeline 8, and the upper end of third pipeline 8 is connected with fourth pipeline 7, and the fourth pipeline 7 Connect with the clean oil tank 1, the running oil tank 3 and the dirty o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com