Press anvil crack detection method

A technology of crack detection and anvil, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, and using acoustic wave emission technology for material analysis, etc. It can solve the impact of difficult-to-predict alternating magnetic field on the detection system, debris and synthetic blocks Splash, top hammer breakage and other problems, to achieve the effect of improving detection continuity and automation, low cost of signal acquisition and analysis, and reducing installation complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

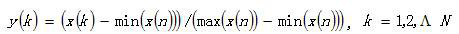

Method used

Image

Examples

Embodiment 1

[0040] As shown in the figure, the top hammer crack detection device of the press top hammer is used to detect the cracks of the top hammer. The top hammer crack detection device of the press includes an acoustic emission detection module 2, a signal adjustment module 3, and a press control cabinet located on one side of the press 6. The press control cabinet 6 is provided with a data acquisition device 4 and a storage device 5 . The acoustic emission detection module 2 includes a piezoelectric element, a preamplifier circuit, a housing, a damping agent, an acoustic coupling agent and cables, and the acoustic emission detection module 2 is installed on the steel ring of the top hammer 1, so that the pressure The electric element is in close contact with the anvil ring, and an acoustic couplant is applied between the piezoelectric element and the anvil ring.

[0041] A method for detecting cracks in an anvil of a press, comprising the following steps:

[0042] Step 1. Install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com