Hole drilling and protecting construction method of soft-broken coal seam

A construction method and hole protection technology, which is applied in the direction of drilling equipment and methods, drill bits, drilling equipment, etc., to achieve the effect of solving the problem of easy collapse and shrinkage of holes, solving the difficulty of gas discharge, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

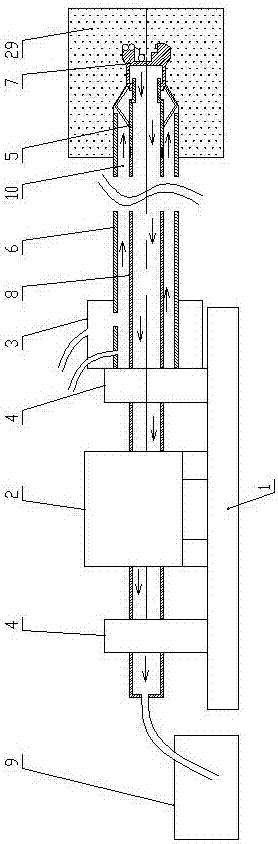

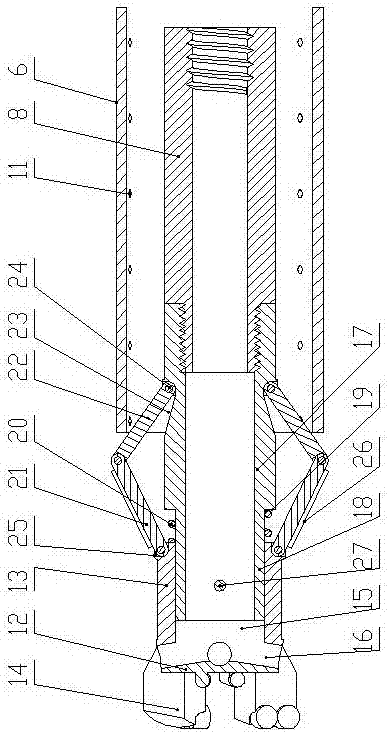

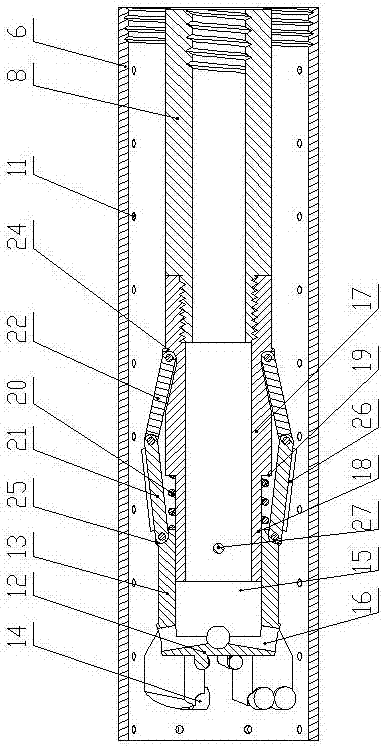

[0025] like Figure 1-Figure 7 As shown, the soft and broken coal seam drilling and reaming device in the present invention includes a support 1, a power drive device 2, a rotary sealing water supply and air supply device 3, a guide support frame 4, a drill connector 5, a hole protection pipe 6, and a central return flow The drill bit 7, the inner chip removal drill pipe 8 and the slag collection container 9, the hole protection pipe 6 is set outside the inner chip removal drill pipe 8, the hole protection pipe 6 and the inner chip removal drill pipe 8 are provided with several pieces, two adjacent Both the hole protection pipes 6 and the adjacent two inner chip removal drill rods 8 are threadedly connected, and an annular channel 10 is formed between the inner wall of the hole protection pipe 6 and the inner chip removal drill rods 8 . In the direction to the front, the rear end of the inner chip removal drill pipe 8 is connected to the slag collection container 9, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com