Fixing type sunshade plate net three-layer sunshade glass arranged in middle

A sun visor and fixed technology, applied in the field of sun shading, can solve the problems of limited sun shading performance, affecting indoor lighting, unable to block direct light well, etc., to achieve simple processing technology, high convenience, and low material and processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

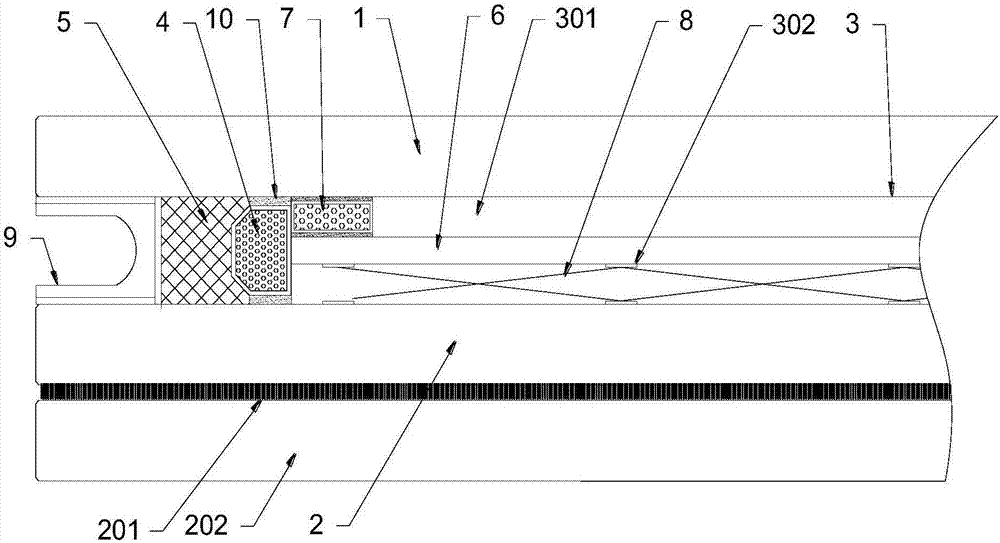

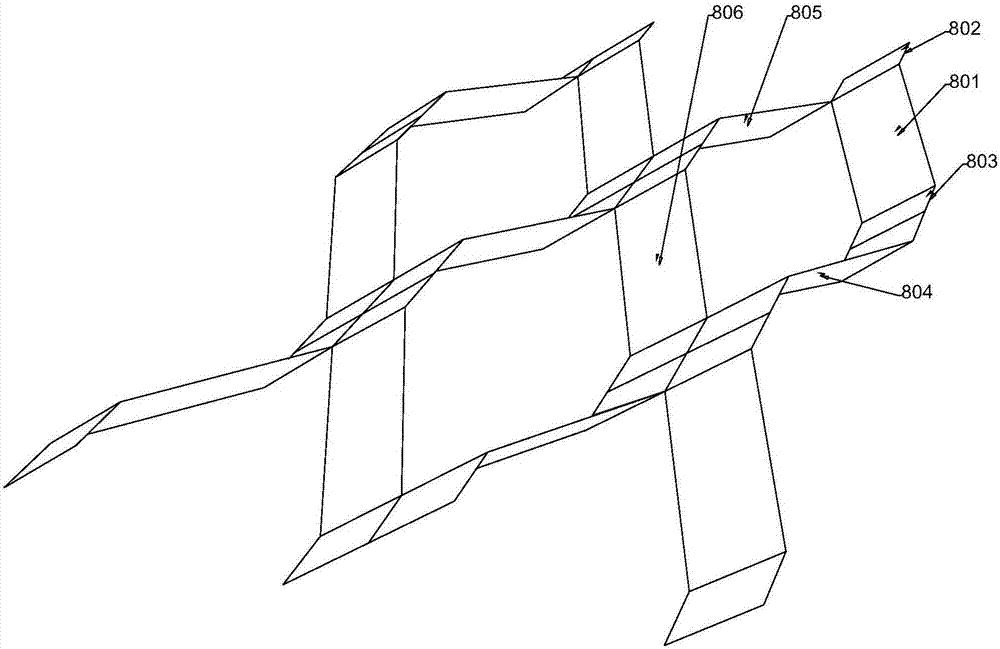

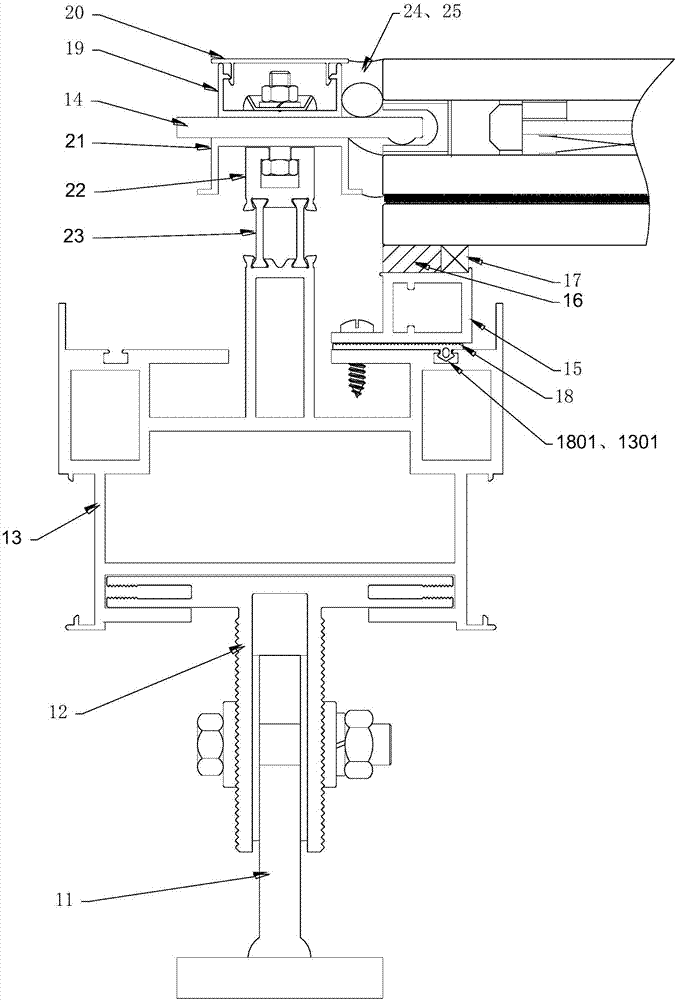

[0022] Such as figure 1 As shown, a three-layer sunshade glass with a fixed sunshade net in the middle includes a first outer layer tempered glass 1, a second outer layer laminated tempered glass 2, the first outer layer tempered glass 1 and the second outer layer laminated glass There is an accommodating cavity 3 between the glue tempered glass 2, and the first outer layer tempered glass 1 and the second outer layer laminated tempered glass 2 are fixedly supported by the first aluminum spacer 4 arranged on the edge, and the first aluminum spacer 4 The exterior is coated with sealing structural glue 5, and the storage chamber 3 is built with a middle tempered glass 6. The middle tempered glass 6 divides the storage chamber 3 into an upper cavity 301 and a lower cavity 302. The upper cavity 301 is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com