A bridge vertical reinforcement tensioning equipment

A vertical reinforcement and tensioning technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve problems such as large differences in vertical prestressing design, inability to consider reinforcement deformation, and irregular tensioning process. , to achieve the effect of shortening the construction period, improving the tensioning efficiency, and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

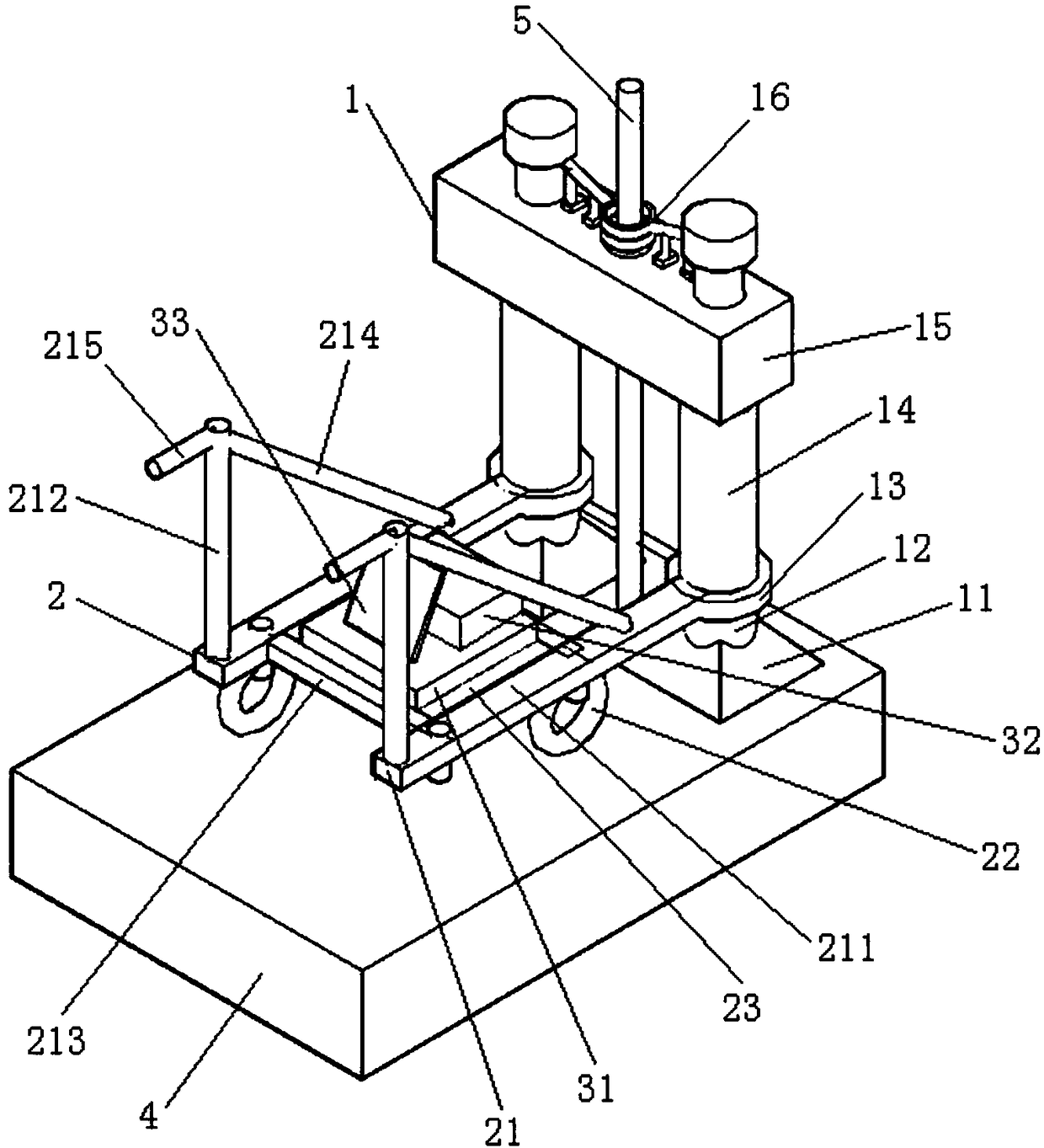

[0017] Such as Figures 1 to 3 As shown, the bridge vertical reinforcement tensioning equipment of the present invention includes a tensioning device 1, a traveling device 2, an energy source and a hydraulic device 3.

[0018] The tensioning device 1 is arranged on the bridge top plate 4 and includes a support base 11 , a support hydraulic rod 12 , a hydraulic rod support plate 13 , a tension hydraulic rod 14 , a tension platform 15 and a steel lever assembly 16 .

[0019] The support base 11 is a pair arranged along the width direction of the top surface of the bridge top plate 4; or bolted to the top of the support base 11; the hydraulic rod support disc 13 also has a pair, and the bottoms of the pair of hydraulic rod support discs 13 are all connected to the upper ends of a pair of support hydraulic rods 12 by welding or bolts; Rod 14 is a pair of vertical setting, and the bottom end of this pair of tensioning hydraulic rod 14 is connected to the top surface of a pair of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com