Nylon taffta dispersion transfer printing color fixation and waterproof finishing method

A transfer printing and waterproof finishing technology, applied in the direction of transfer printing, dyeing, printing, etc., can solve the problem that the waterproof effect cannot be improved, the product cannot meet the customer's requirements, and the transfer fastness difference is only grade 1 or 1-2. and other problems, to achieve the effect of improving transfer fastness, reducing the chance of bonding, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

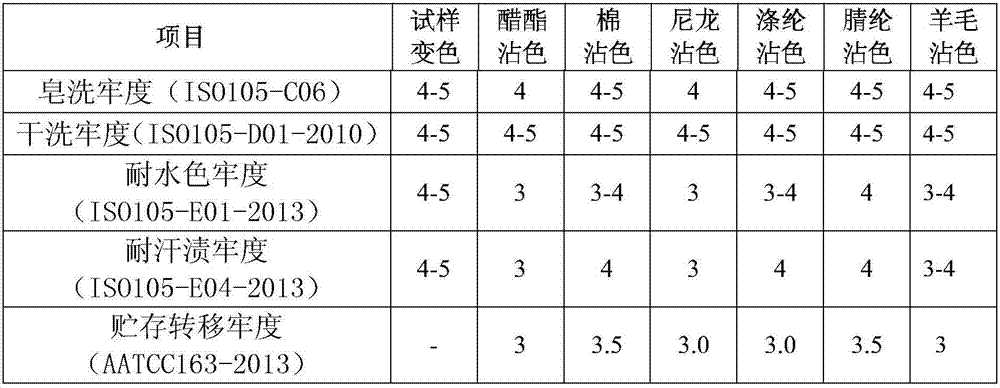

Examples

Embodiment 1

[0021] Embodiment 1, a method for color-fixing and waterproof finishing of Nisi spinning disperse transfer printing comprises the following steps:

[0022] (1) First use nylon special dye sublimation ink to carry out thermal transfer printing on nylon spinning;

[0023] (2) Prepare a certain concentration of color-fixing agent DM-2535 to carry out color-fixation treatment on the printed nylon yarn, two dips and two rollings, and wait for water rolling;

[0024] (3) After fixing the color, rinse with water, dry, and wait for waterproof finishing;

[0025] (4) Use waterproofing agent DH-3674 to carry out water-repellent treatment on the Nisi spinning after padding and drying, one soaking and one rolling, drying and baking.

[0026] In the heat transfer printing in the step (1), the transfer temperature (190~200°C, transfer time 25±15sec, transfer pressure 0.5Kg / cm 2 )

[0027] In the color-fixing treatment process in the step (2), the dosage of the acidic color-fixing agent D...

Embodiment 2

[0031] Embodiment 2, a method for color-fixing and waterproof finishing of nylon spun disperse transfer printing comprises the following steps

[0032] (1) First use nylon special dye sublimation ink to carry out thermal transfer printing on nylon spinning;

[0033] (2) Prepare a certain concentration of color-fixing agent DM-2535 to carry out color-fixation treatment on the printed nylon yarn, two dips and two rollings, and wait for water rolling;

[0034] (3) After fixing the color, rinse with water, dry, and wait for waterproof finishing;

[0035] (4) Use waterproofing agent DH-3674 to carry out water-repellent treatment on the Nisi spinning after padding and drying, one soaking and one rolling, drying and baking.

[0036] In the heat transfer printing in the step (1), the transfer temperature (190~200°C, transfer time 25±15sec, transfer pressure 0.5Kg / cm 2 )

[0037] In the color-fixing treatment process in the step (2), the acid color-fixing agent DM-2535 is used in an...

example 1

[0044] Preparation process:

[0045] Fabric type: 210T glossy whitening nylon spinning 500 meters;

[0046] Equipment: MH591-180 skew rolling mill (Fong's);

[0047] VJ1638 digital printer (MUTON);

[0048] Transfer temperature: 190°C

[0049] Transfer time: 30sec

[0050] Transfer pressure: 0.5Kg / cm 2

[0051] Speed: 10m / min;

[0052] Pressure: 1.0kg / cm 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com