Integrated rudder-enhancing textile and knitting method thereof

A technology for reinforcing fabrics and fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems that cannot meet the bearing capacity of the control rudder, and achieve the effects of good bending resistance, strong operability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

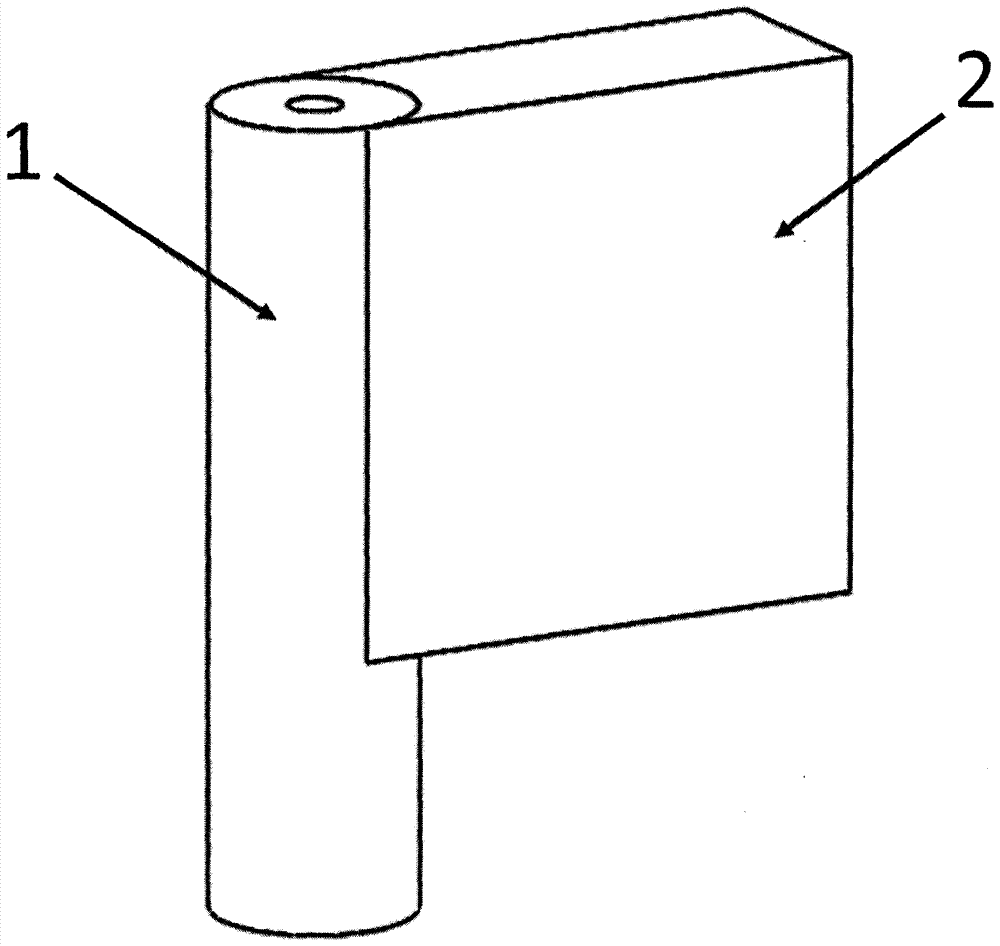

[0037] Develop an integral rudder reinforcement fabric, the outer diameter of the hollow rudder shaft is 30mm, the inner diameter is 15mm, and the length is 90mm; the width of the rudder surface is 60mm, the thickness is 30mm, and the length is 60mm. Warp yarn 4, weft yarn 5, normal yarn 6, +θ diagonal yarn 7 and -θ diagonal yarn 8 are all 12K carbon fibers. The yarn arrangement density in the fabric cross section is 6×6 / cm 2 , the diagonal yarn arrangement is [45 / -45] 2, where 45 represents the inclination angle between +θ oblique yarn 7 and the length direction of the fabric is 45°, -45 represents the inclination angle between -θ oblique yarn 8 and the length direction of the fabric is -45°, subscript 2 represents the oblique yarn The number of groups is 2 groups.

[0038] Fabric process parameter design:

[0039] (1) The hollow cylinder-shaped rudder shaft is transformed into a hollow cube-shaped rudder shaft. The outer diameter of the converted rudder shaft corresponds ...

Embodiment 2

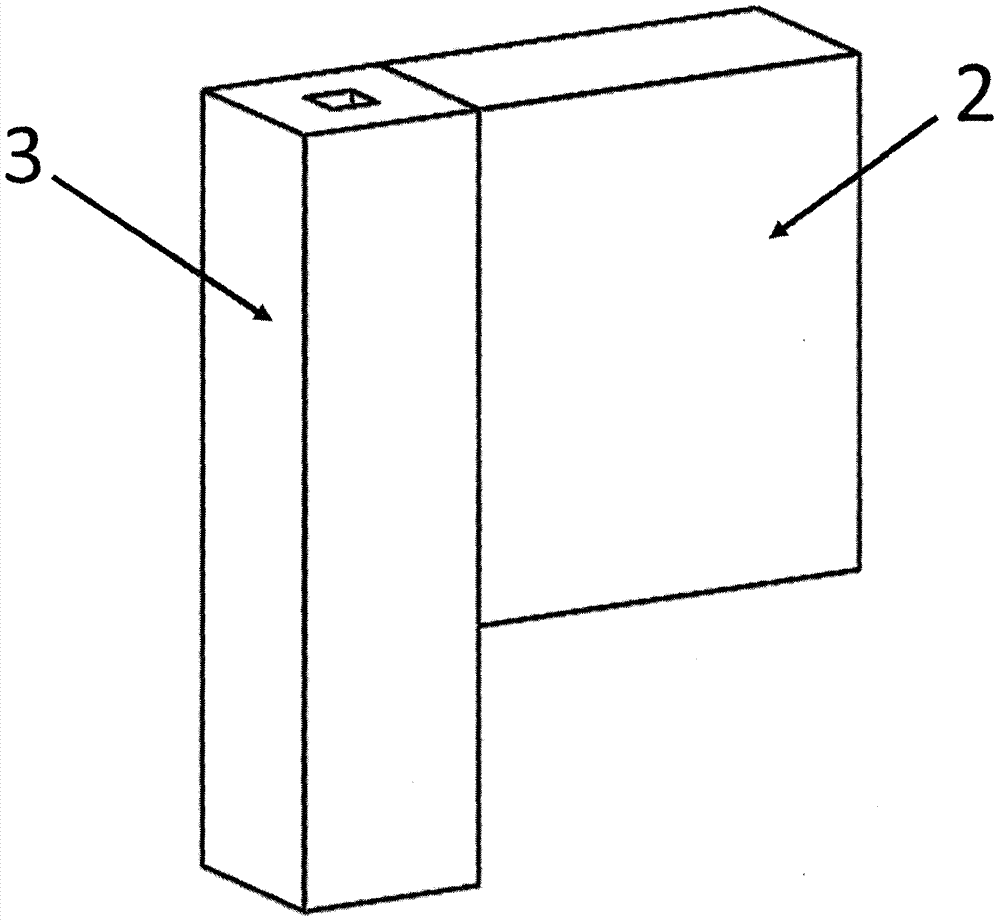

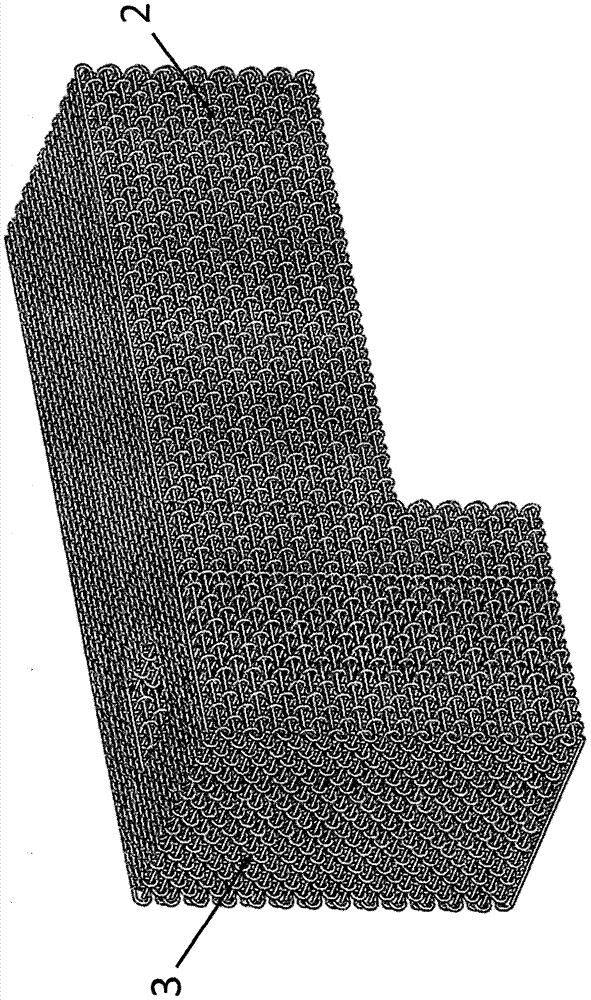

[0056] Develop an integral rudder reinforcement fabric (see attached Figure 10 ), the rudder shaft is located in the middle of the control rudder, the size of the rudder shaft is 80×80mm, the inner hole is 20×20mm, and the length is 600mm; 200mm, thickness 80mm, length 300mm. Warp yarn 4, normal yarn 6, +θ oblique yarn 7 and -θ oblique yarn 8 are all 12K carbon fibers, and weft yarn 5 is 3K×5 strands of carbon fiber. The yarn arrangement density in the cross section of the fabric is 5×5 yarns / cm 2 , the weft density is 6 threads / cm 2 , the oblique yarn arrangement is [θ / -θ] 3 .

[0057] Fabric process parameter design:

[0058] (1) The number of yarn rows (columns) in the rudder shaft area I: the number of yarn rows (columns) = fabric cross-sectional thickness (width) × yarn row (column) density + 1, and the inner yarn row (column) of the circumscribed square ( Column) number N=80 / 10×5+1=41 rows (columns), yarn row (column) number C=20 / 10×5+1=11 rows (columns) in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com