Aluminum electrolysis high-temperature smoke and aluminum ladle combined conveying system

A technology of high-temperature flue gas and conveying system, which is applied in the field of aluminum electrolysis, can solve the problems of low temperature of aluminum electrolysis flue gas and is not suitable for recycling and processing, and achieve the effects of optimizing aluminum electrolysis operation, reducing energy loss, and reducing labor workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

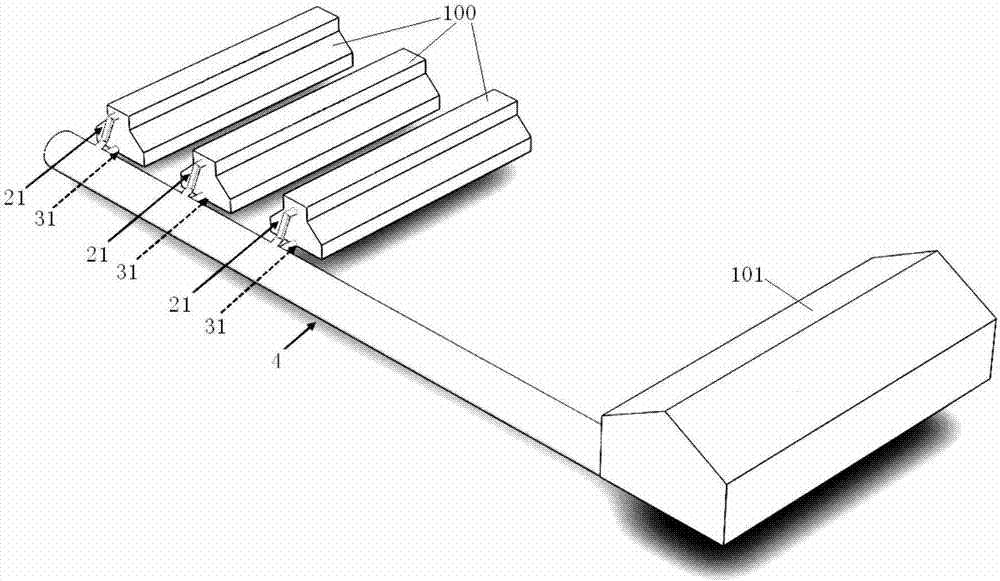

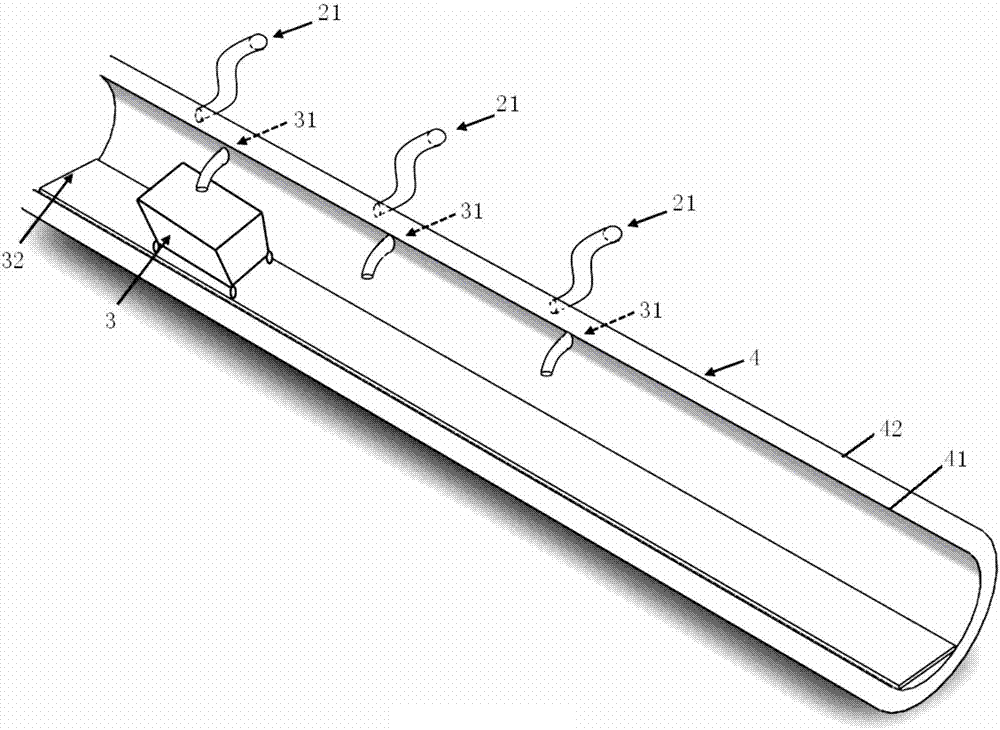

[0019] see figure 1 and figure 2 , the conveying pipeline in the illustration is a preferred solution of the present invention, which provides a combined conveying scheme of aluminum electrolysis high-temperature flue gas and aluminum ladle, including conveying pipeline 4 for conveying aluminum ladle and high-temperature flue gas and automatic aluminum tapping Package 3, aluminum outlet pipe 31, aluminum outlet track 32, wherein the transportation pipeline 4 is a two-layer composite structure, including an inner pipeline 41 and an outer pipeline 42 that are set inside and outside, wherein the inside of the inner pipeline 41 is used for the pipeline for aluminum package transportation, Connect the aluminum electrolytic cell 100 and the melting and casting workshop 101 respectively, and the interior is equipped with an aluminum ladle self-feeding and conveying component to realize the automatic delivery of the aluminum ladle to automatically transport the molten aluminum in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com